Enhanced high-density ductile anti-channeling cement slurry for oil and gas well cementing

An enhanced, high-density technology, applied in the field of petroleum drilling engineering, can solve the problems that it is difficult to ensure the long-term sealing performance of the cement sheath, reduce the compressive strength of cement slurry, and cannot be used for well cementing, so as to achieve rheology and stability Good effect of improving compressive strength and fast gelling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

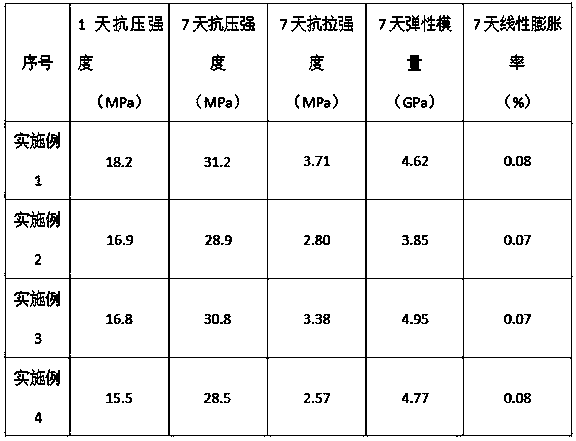

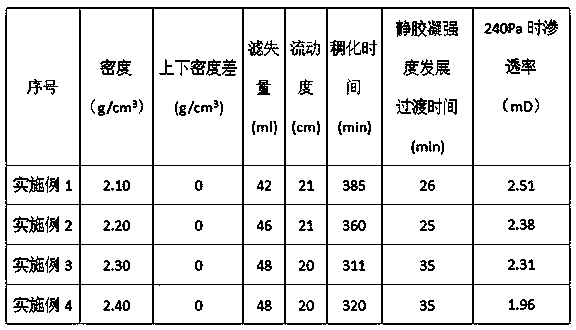

Embodiment 1

[0021] Weigh 500g G grade oil well cement, 330g iron ore powder, 120g silicon powder, 50g reinforcing agent, 50g flexible anti-channeling agent, 10g dispersant, 5g toughening agent, 30g fluid loss reducer, 10g retarder, 1g defoamer , 289g tap water. Dry mix iron ore powder, silicon powder, reinforcing agent, flexible anti-channeling agent, toughening agent and dispersant with cement first, then add fluid loss reducer, retarder and defoamer into tap water and mix evenly, press Prepare cement slurry according to GB / T19139-2012 standard.

Embodiment 2

[0023] Weigh 420g G grade oil well cement, 430g iron ore powder, 100g silicon powder, 50g reinforcing agent, 50g flexible anti-channeling agent, 10g dispersant, 5g toughening agent, 30g fluid loss reducer, 10g retarder, 1g defoamer , 269g tap water. Dry mix iron ore powder, silicon powder, reinforcing agent, flexible anti-channeling agent, toughening agent and dispersant with cement first, then add fluid loss reducer, retarder and defoamer into tap water and mix evenly, press Prepare cement slurry according to GB / T19139-2012 standard.

Embodiment 3

[0025] Weigh 450g G grade oil well cement, 400g iron ore powder, 110g silicon powder, 40g reinforcing agent, 50g flexible anti-channeling agent, 10g dispersant, 5g toughening agent, 25g fluid loss reducer, 10g retarder, 1g defoamer , 244g tap water. Dry mix iron ore powder, silicon powder, reinforcing agent, flexible anti-channeling agent, toughening agent and dispersant with cement first, then add fluid loss reducer, retarder and defoamer into tap water and mix evenly, press Prepare cement slurry according to GB / T19139-2012 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com