A biodegradable high-strength-tough-corrosion-resistant magnesium alloy for orthopedics and preparation method thereof

A magnesium alloy and biological technology, which is applied in the field of high-strength, toughness and corrosion-resistant orthopaedic magnesium alloy and its preparation, and achieves the effects of increasing the degree of supercooling, reducing the activation energy of nucleation, and increasing the rate of nucleation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

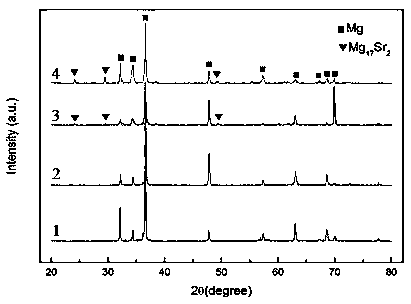

[0033] In the present embodiment, the raw material composition is as follows: Sr 0.5%, Zr 0.4%, the rest is Mg and contains a small amount of impurity elements Fe, Ni, Al, Cu, impurity elements are calculated by mass percentage, and each content is no more than 0.1%. The amount does not exceed 0.4%.

[0034]The preparation method of magnesium alloy in the present embodiment is as follows:

[0035] First, use ZnO and talcum powder paint to evenly brush the inner wall of the self-made non-magnetic stainless steel crucible to white, and preheat the slag removal spoon, stirring spoon, and mold to 200°C; then when the furnace temperature rises to 400°C, put 500g magnesium block Put it into the crucible and continue to heat up to 710°C, keep it warm for 15 minutes to melt the magnesium block; when the temperature of the magnesium-based melt rises to 750°C, remove the slag, add 2.5g of pure Sr and 6.6g of Mg-30wt.%Zr master alloy at the same time , use a stirring spoon to stir sligh...

Embodiment 2

[0040] In the present embodiment, the raw material composition is as follows: Sr 4.0%, Zr 0.7%, the rest is Mg and contains a small amount of impurity elements Fe, Ni, Al, Cu, impurity elements are calculated by mass percentage, and each content is no more than 0.1%. The amount does not exceed 0.4%.

[0041] The preparation method of magnesium alloy in the present embodiment is as follows:

[0042] First, use ZnO and talcum powder paint to evenly brush the inner wall of the self-made non-magnetic stainless steel crucible to white, and preheat the slag removal spoon, stirring spoon, and mold to 205°C; then when the furnace temperature rises to 420°C, put 500g magnesium block Put it into the crucible and continue to heat up to 720°C, keep it warm for 20 minutes to melt the magnesium block; when the temperature of the magnesium-based melt rises to 760°C, remove the slag, add 21.3g of pure Sr and 12.3g of Mg-30wt.%Zr master alloy at the same time, Use a stirring spoon to stir sli...

Embodiment 3

[0047] In the present embodiment, raw material composition is as follows: Sr 0.5%, Zr0.5%, all the other are Mg and contain a small amount of impurity element Fe, Ni, Al, Cu, impurity element is calculated by mass percentage, each content is no more than 0.1%, The total amount shall not exceed 0.4%.

[0048] The preparation method of magnesium alloy in the present embodiment is as follows:

[0049] First, paint the inner wall of the self-made non-magnetic stainless steel crucible evenly with ZnO and talcum powder to white, and preheat the slag removal spoon, stirring spoon, and mold to 210°C; then when the furnace temperature rises to 430°C, put 500g magnesium block Put it into the crucible and continue to heat up to 715°C, keep it warm for 18 minutes to melt the magnesium block; when the temperature of the magnesium-based melt rises to 755°C, remove the slag, add 2.6g of pure Sr and 8.35g of Mg-30wt.%Zr master alloy at the same time , use a stirring spoon to stir slightly be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com