Carbon fiber reinforced wear-resistant high-temperature nylon composite and preparation method thereof

A nylon composite material and carbon fiber technology, applied in the field of high temperature nylon materials, can solve the problems of long fiber length, complex process, reduction of material friction coefficient and wear, etc., and achieve the effect of low friction coefficient, excellent comprehensive performance and improved bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

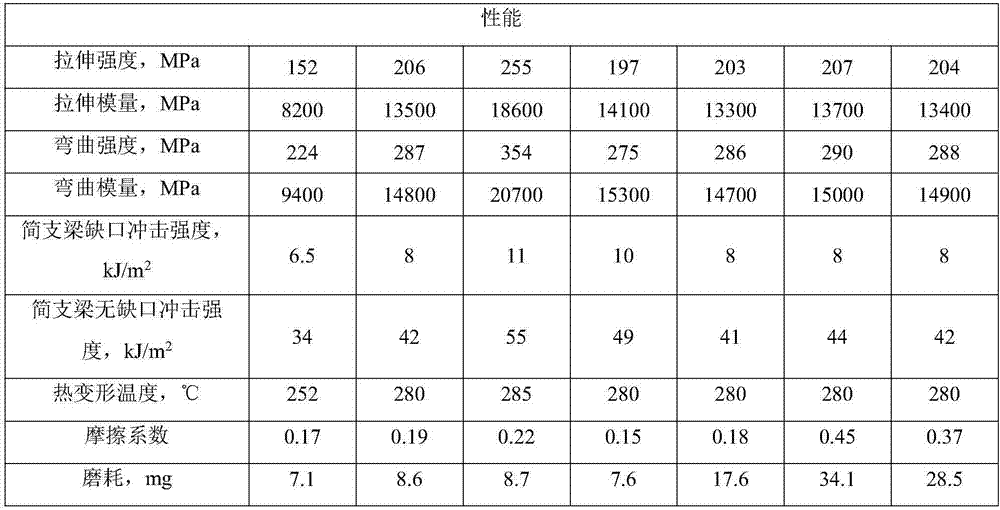

Embodiment 1

[0034] A carbon fiber-reinforced wear-resistant high-temperature nylon composite material, the components and contents of which are shown in Table 1 below, wherein the Mohs hardness of the soft filler is ≤2, the Mohs hardness of the hard filler is ≥5, and the carbon fiber is made of nitric acid liquid phase The PAN-based ground carbon fiber after the oxidation treatment, the single filament diameter of the PAN-based ground carbon fiber before the nitric acid liquid phase oxidation treatment is 7 μm, and the average fiber length is 100 μm.

[0035] The preparation method of the carbon fiber reinforced wear-resistant high-temperature nylon composite material is as follows:

[0036] (1) Put the soft filler and the hard filler in an electric blast drying oven, dry them at 100°C for 8 hours, and mix them evenly to obtain a mixed filler. Dissolve the coupling agent in isopropanol to prepare a coupling agent solution , and keep the mass of isopropanol 20 times the mass of the couplin...

Embodiment 2-4

[0041] A carbon fiber-reinforced wear-resistant high-temperature nylon composite material, compared with Example 1, differs in the content of its constituent components, and the specific differences are shown in Table 1 below. The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com