Mobile Gaza wave-making muddy water model test device and method with automatic sand removal function

A model test device and automatic cleaning technology, applied to hydraulic models, etc., can solve problems such as failure to meet the requirements of simulation tests, free movement of Gaza equipment, and coupling of wave-making systems that cannot meet test requirements, so as to avoid blockage and ensure concentration Uniformity, the effect of correcting wave-making errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but should not be construed as limiting the present invention.

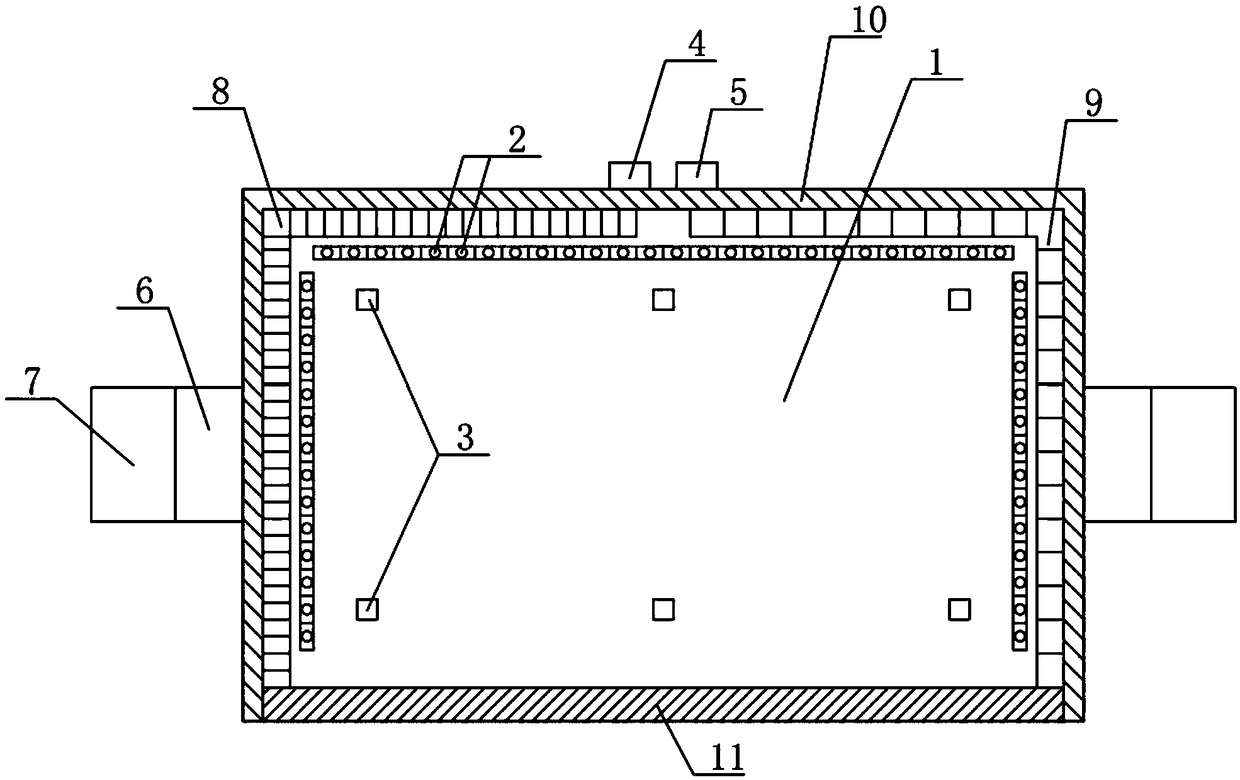

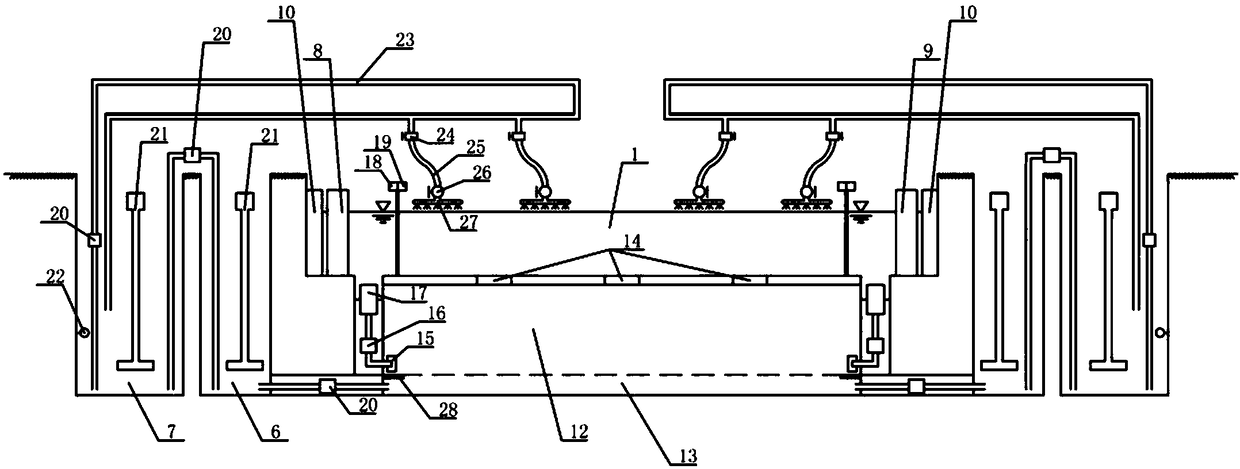

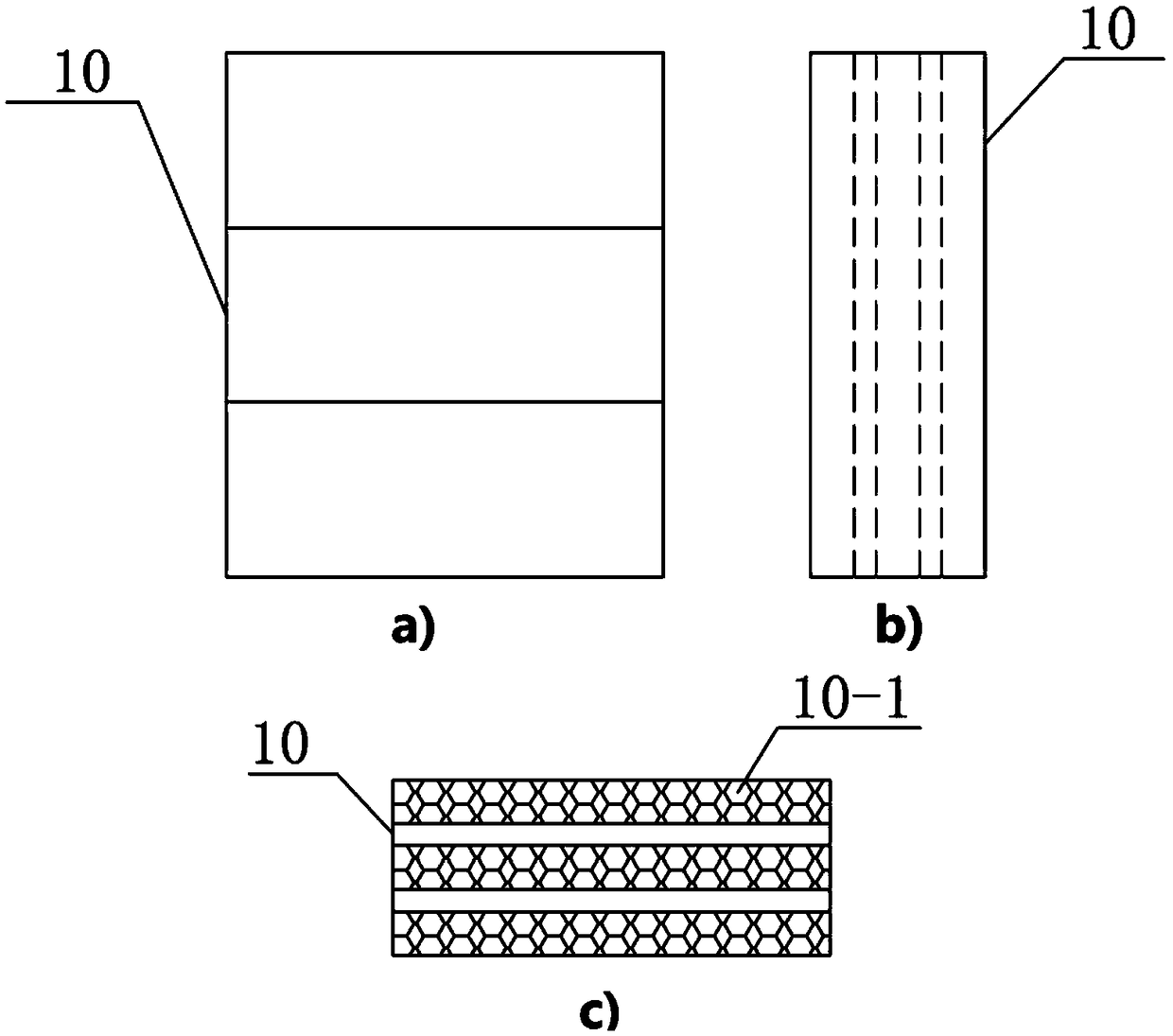

[0036] Such as Figure 1 to Figure 2 As shown, a mobile Gaza wave-making muddy water model test device with automatic sand cleaning function includes a test pool system, a wave-making system, a Gaza sand cleaning system, a monitoring system 3, and a control system. The implementation of each system is as follows:

[0037]The test pool system includes a test pool 1 , an underground reservoir 12 , and a drainage hole 14 . Wherein the test pool 1 is the layout area of wading engineering structures; the underground reservoir 12 is located below the test pool 1, as a place for storing and collecting test water, and the bottom of the test pool is provided with a drainage hole 14, which is used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com