Power semiconductor device and manufacturing method thereof

A technology of power semiconductors and devices, which is applied in the field of power semiconductor devices and their production, and can solve problems such as controlling base reverse bias turn-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

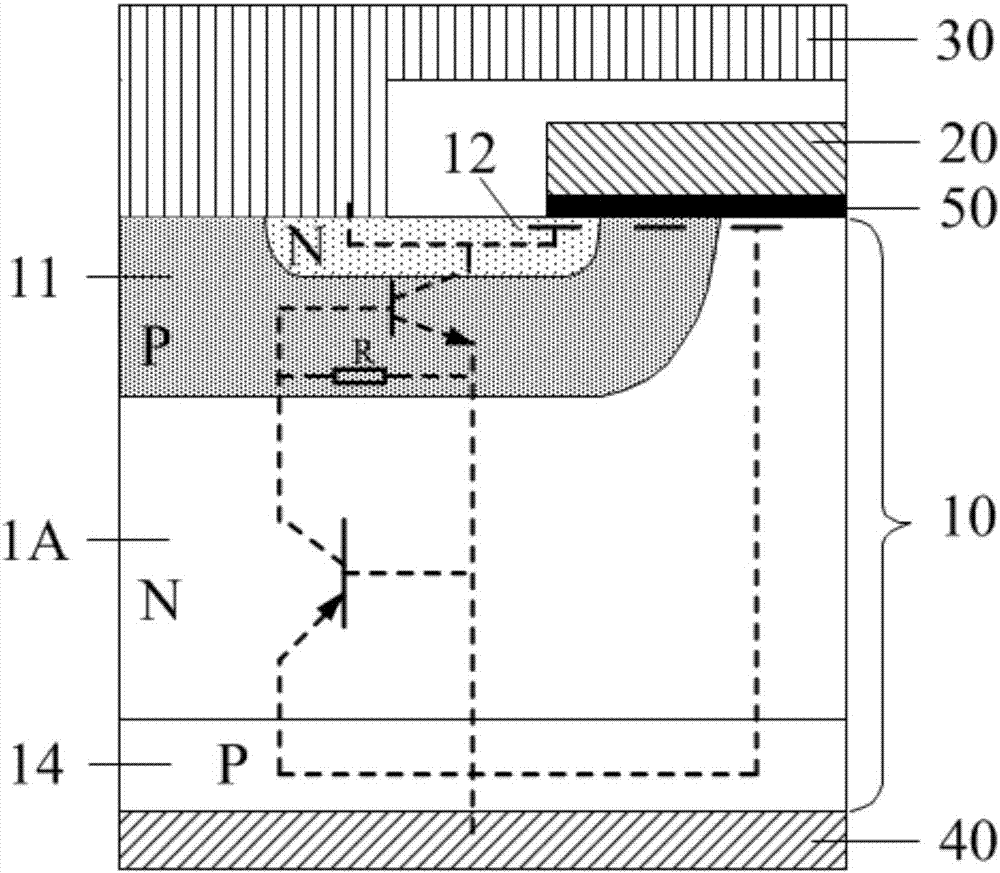

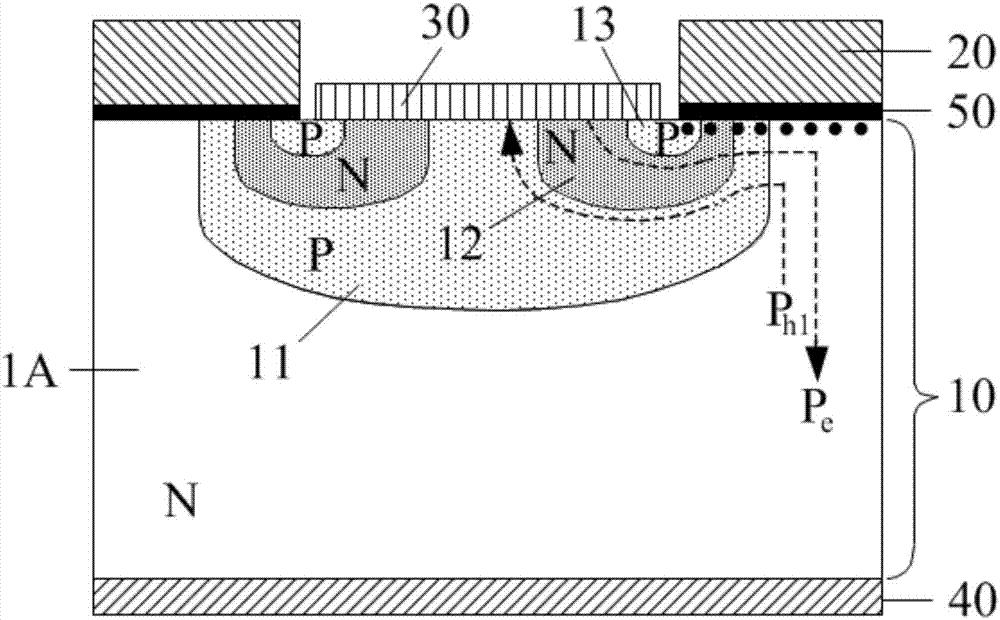

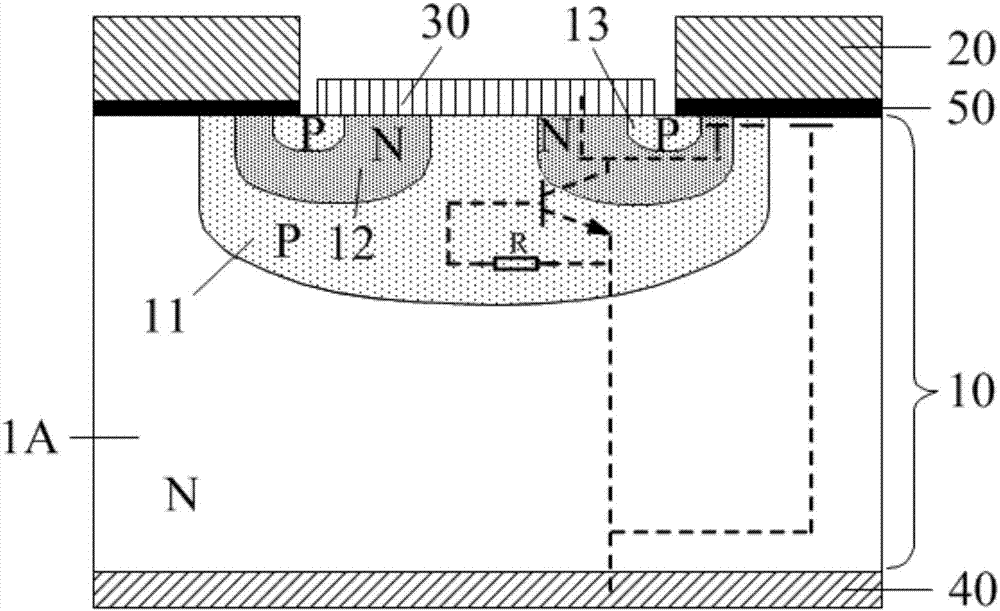

[0028] An embodiment of the present invention provides a power semiconductor device, such as Figure 2 to Figure 4 As shown, the power semiconductor device includes a substrate 10, a first doped layer 11, a second doped layer 12, a third doped layer 13, a control electrode 20, a first electrode 30 and a second electrode 40, wherein the control electrode 20 may be, for example, a gate or a base, the first electrode 30 may be, for example, a source or a collector, and the second electrode may be, for example, a drain or an emitter.

[0029] The substrate 10 has a first surface and a second surface opposite to the first surface, and the substrate 10 is of the first conductivity type, Figure 2 to Figure 4 1A is the original doping type layer of the substrate 10 , that is, the first conductivity type. The first doped layer 11 is disposed in the substrate 10 and is of a second conductivity type opposite to the first conductivity type. The second doped layer 12 is disposed in the ...

Embodiment 2

[0042] An embodiment of the present invention provides a power semiconductor device, such as Figure 5 to Figure 7 As shown, the power semiconductor device includes a substrate 10, a first doped layer 11, a second doped layer 12, a third doped layer 13, a control electrode 20, a first electrode 30, and a second electrode 40. For details, please refer to Implementation example one. The difference between the embodiment of the present invention and the first embodiment is that the fourth doped layer 14 is further included. The fourth doped layer 14 is disposed between the substrate 10 and the second electrode 40 , and the fourth doped layer 14 is of the second conductivity type.

[0043] The working principle of the above-mentioned power semiconductor device will be described below with the first conductivity type being N-type and the second conductivity type being P-type.

[0044] When the control electrode 20 is connected to a positive voltage, such as Figure 5 As shown, m...

Embodiment 3

[0054] An embodiment of the present invention provides a method for manufacturing a power semiconductor device, which is used to manufacture the power semiconductor device described in Embodiment 1, such as Figure 8 As shown, this step includes the following steps:

[0055] S101: Form a first doped layer in a first surface of a substrate of a first conductivity type, where the first doped layer is of a second conductivity type opposite to the first conductivity type.

[0056]S102: Form a second doped layer of the first conductivity type in the first doped layer.

[0057] S103: forming a third doped layer of the second conductivity type in the second doped layer.

[0058] S104: forming an isolation layer on the first surface of the substrate, the isolation layer is in contact with surfaces of the first doped layer, the second doped layer, and the third doped layer.

[0059] S105: forming a control electrode on the isolation layer.

[0060] S106: forming a first electrode on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com