Atomization synthesizer and application thereof in synthesis of alkylaluminoxane

A technology of chemical synthesis and stirring devices, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical nozzle reactors, etc., can solve problems that are not suitable for industrial production and operation High risk, complex equipment operation and other problems, to achieve good catalytic effect, low energy/material consumption, stable reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

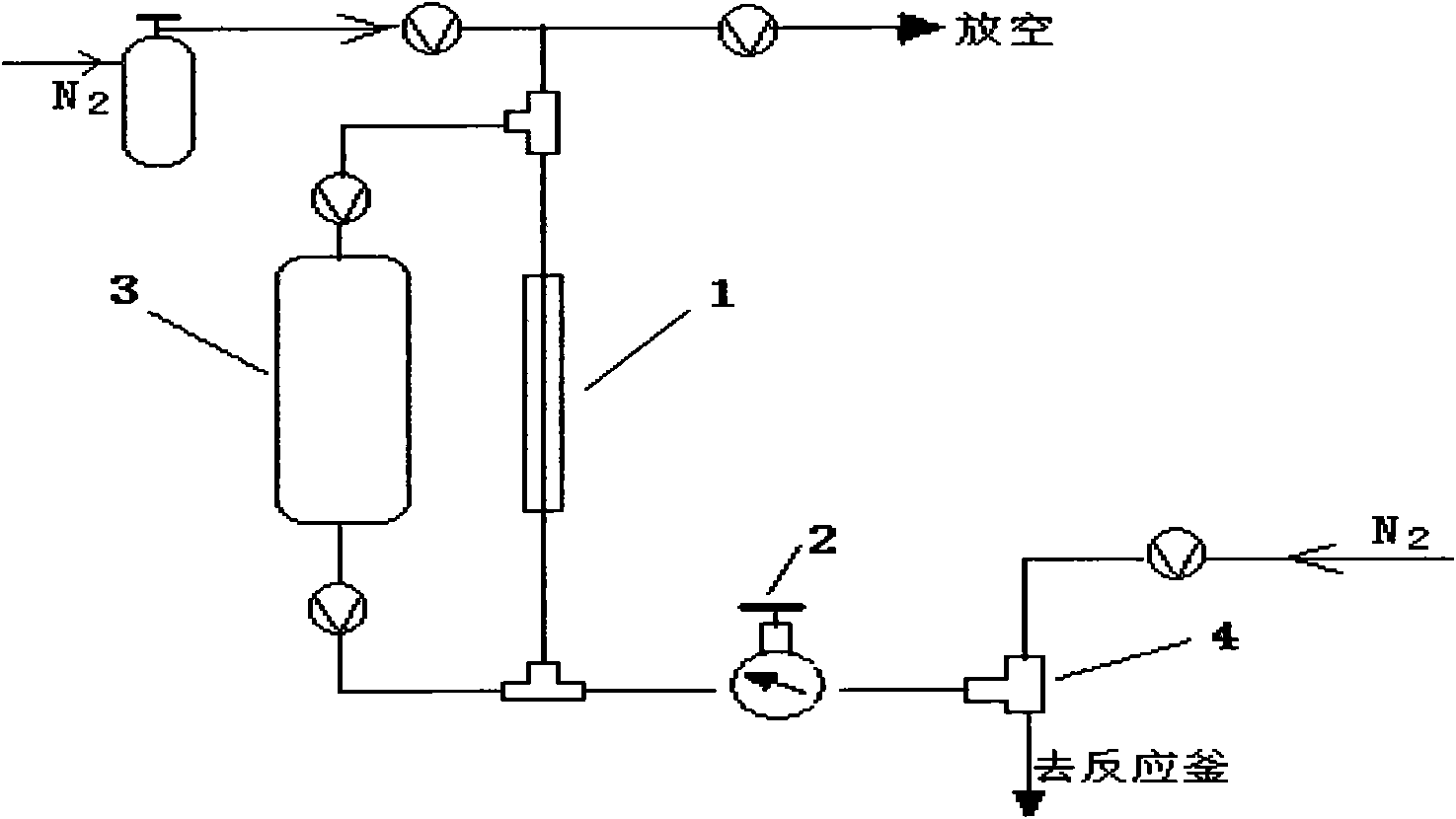

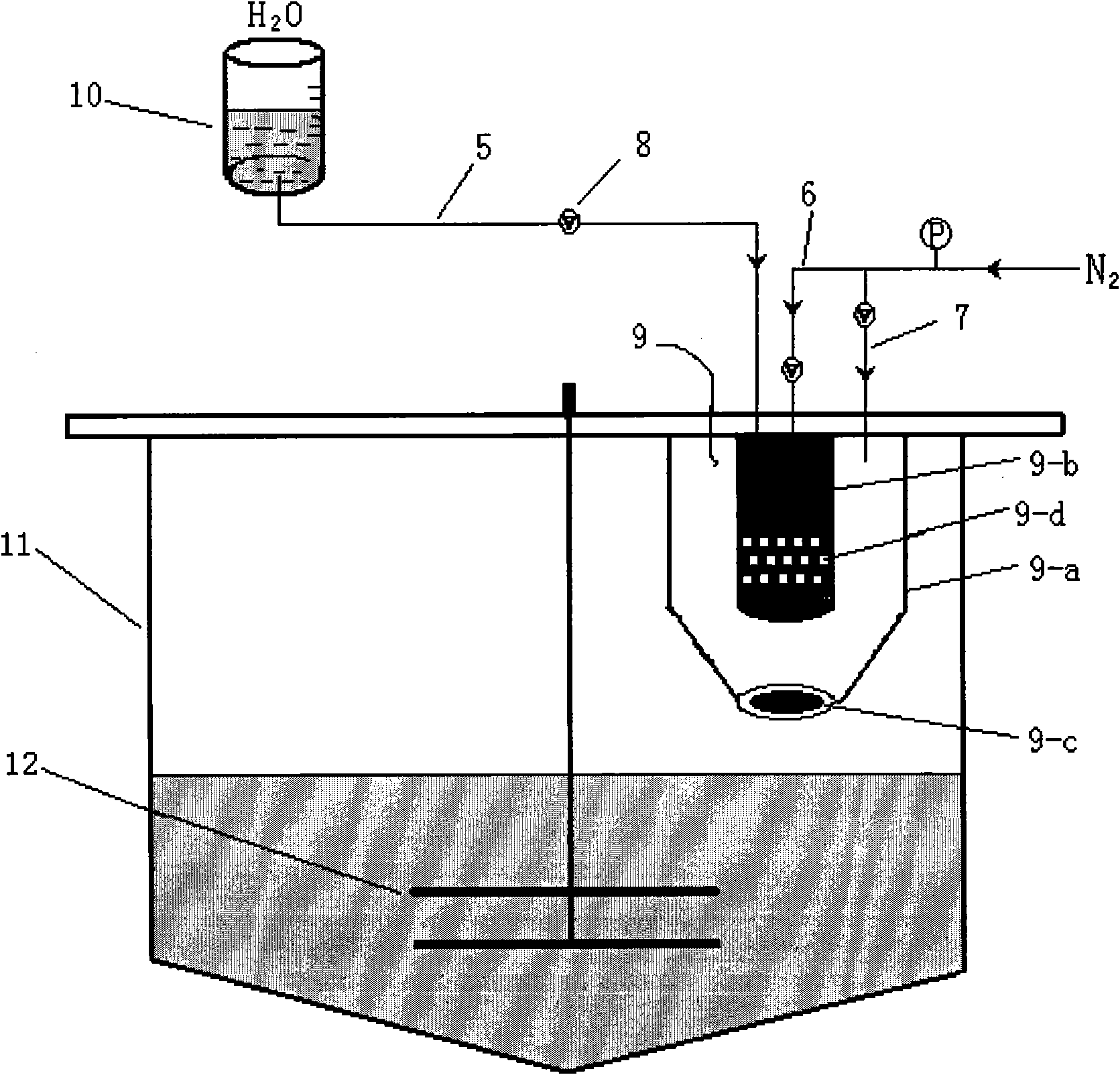

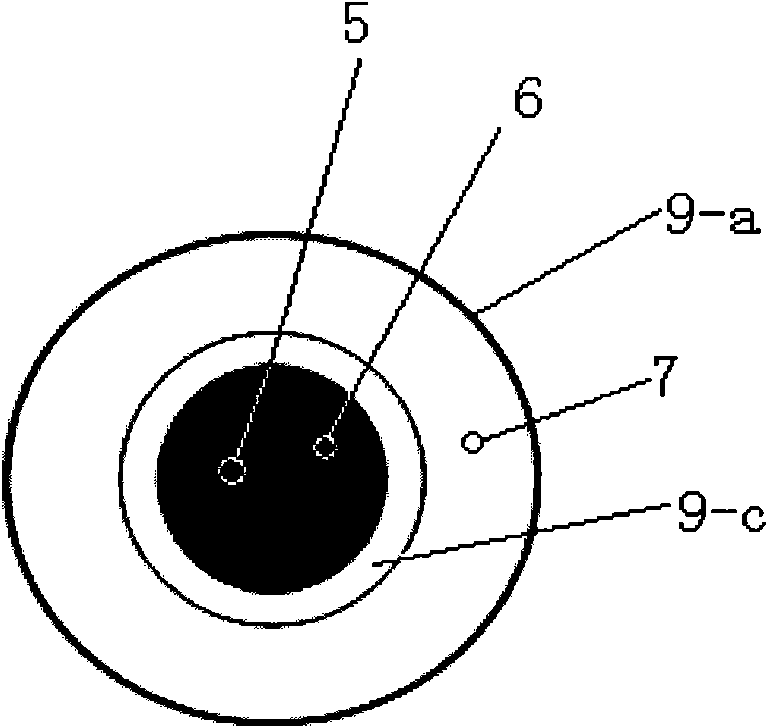

Method used

Image

Examples

Embodiment 1

[0031] Add 250ml of 3.0mol·L -1Trimethylaluminum (TMA) / toluene solution, start stirring, when the temperature of the solution in the reaction bottle is reduced to -20°C, adopt the device of the present invention to gradually add 9.5ml of atomized deionized water in the reaction bottle within 5min; When no obvious bubbles were released in the reaction flask, the temperature was gradually raised to 40°C, and the stirring was continued for 5 hours to stop the reaction. use G 4 The reaction solution was filtered through a sand core, and the solvent was removed under reduced pressure to obtain 27.4 g of white methylaluminoxane solid, with a yield of 62.9%.

Embodiment 2

[0036] Add 250ml of 3.0mol·L -1 Stir the triisobutylaluminum / toluene solution, and when the temperature of the solution in the reaction bottle drops to -25°C, gradually add 10ml of atomized deionized water into the reaction bottle within 5 minutes through the device of the present invention. After the addition, the temperature was gradually raised to 75° C., and the stirring was continued for 5 hours to stop the reaction. use G 4 The reaction solution was filtered through a sand core, and the solvent was removed under reduced pressure to obtain 43.9 g of white isobutylaluminoxane solid, with a yield of 60.5%.

Embodiment 3

[0038] After the 1 liter reaction bottle equipped with nitrogen, venting and cooling system has been fully vacuum-nitrogen replaced, add 100ml of 2.0mol·L -1 Trimethylaluminum (TMA) / toluene solution and 100ml 3.0mol L -1 Triisobutylaluminum / toluene solution, start stirring, and when the temperature of the solution in the reaction bottle is reduced to -20°C, gradually add 5.4ml of deionized water atomized by the device of the present invention into the reaction bottle within 2min; When no obvious bubbles were released, the temperature was gradually raised to 40°C, and stirring was continued for 5 hours to stop the reaction. use G 4 The reaction solution was filtered through a sand core, and the solvent was removed under reduced pressure to obtain 24.9 g of a white modified alkylaluminoxane solid, with a yield of 61.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com