A kind of preparation method of composite bone repair material

A bone repair and freeze-dried bone technology, applied in the field of biomedical engineering, can solve problems such as deep wound infection, affecting surgical efficacy, and graft settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

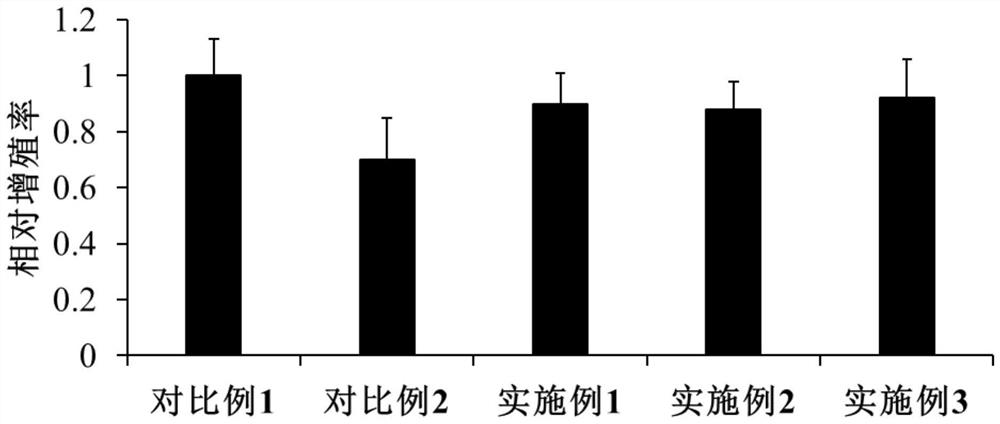

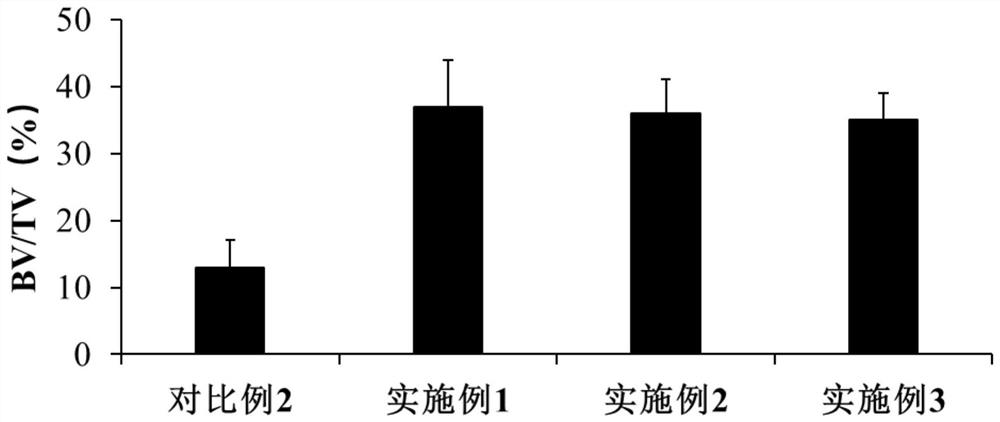

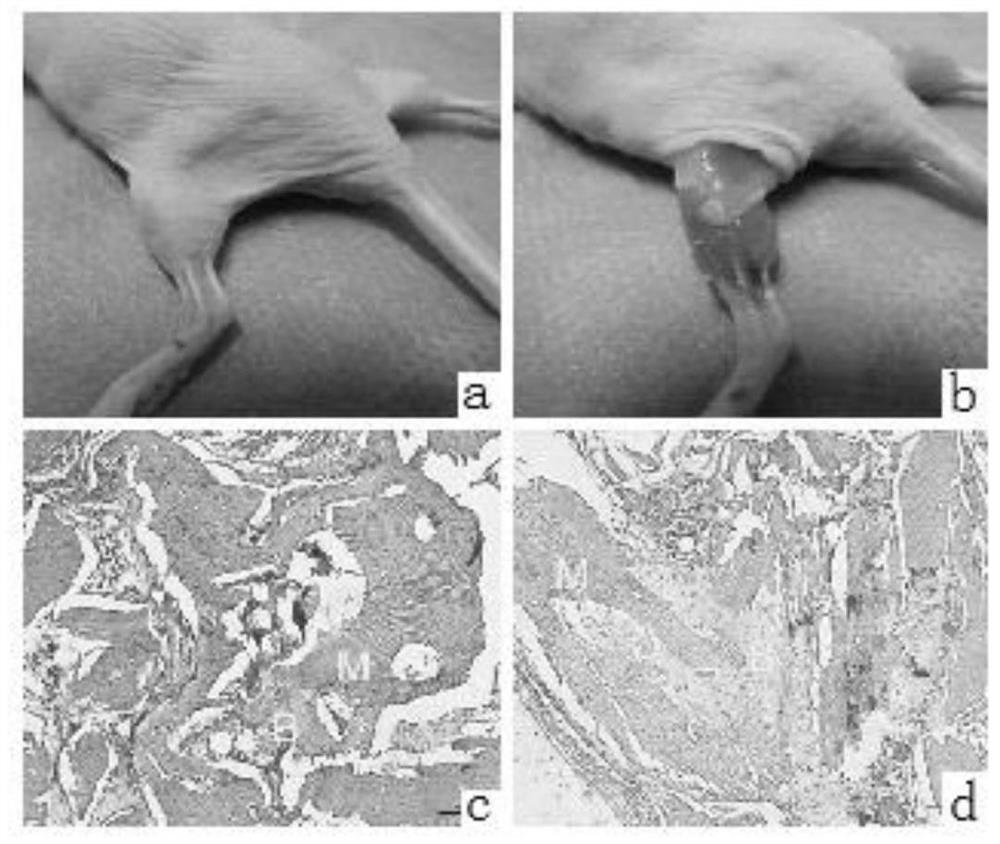

Examples

Embodiment 1

[0033] The preparation method of the composite bone repair material of this embodiment comprises the following steps:

[0034]Step 1. Preparation of allogeneic freeze-dried bone (FDB): remove the soft tissue of the donor, cut the bone into 3-8mm×3-8mm×3-8mm, freeze at -80°C for 5w, initially remove the antigenicity, and further remove Clean soft tissue, degrease with supercritical carbon dioxide according to the content recorded in the patent number ZL201510134565.3, vacuum freeze-dry at -40°C for 72 hours, and sterilize by irradiation;

[0035] Step 2, prepare hot dog ridge polar extract (PRCHP) solution:

[0036] 1) Prepare scalded dog ridge: take the cleaned dog ridge slices of uniform size, put 8 times the amount of river sand in a pot, heat to control the temperature of the river sand at 180°C, put in the dog ridge slices, fry and bury them , fry for 6.5 minutes, take out and sieve to remove sand, let cool, set aside;

[0037] 2) Polysaccharide extract of dog ridge: tak...

Embodiment 2

[0043] The preparation method of the composite bone repair material of this embodiment comprises the following steps:

[0044] Step 1. Preparation of allogeneic freeze-dried bone (FDB): same as in Example 1;

[0045] Step 2, prepare hot dog ridge polar extract (PRCHP) solution:

[0046] 1) Prepare scalded dog ridge: take the cleaned dog ridge slices of uniform size, put 8 times the amount of river sand in a pot, heat to control the temperature of the river sand at 190°C, put in the dog ridge slices, fry and bury them , fry for 6 minutes, take out the sieve to remove the sand, let cool, and set aside;

[0047] 2) Polysaccharide extract of dog ridge: take scalded dog ridge of uniform size, crush it through a 100-mesh sieve to obtain hot dog ridge powder, decoct it with 8 times the amount of water for 40 minutes each time, and combine the decoction liquid , concentrated under reduced pressure, added ethanol to make the final concentration 80%, kept overnight, and obtained crude...

Embodiment 3

[0053] The preparation method of the composite bone repair material of this embodiment comprises the following steps:

[0054] Step 1. Preparation of allogeneic freeze-dried bone (FDB): same as in Example 1;

[0055] Step 2, prepare hot dog ridge polar extract (PRCHP) solution:

[0056] 1) Prepare scalded dog ridge: take the cleaned dog ridge slices of uniform size, put 8 times the amount of river sand in a pot, heat to control the temperature of the river sand at 180°C, put in the dog ridge slices, fry and bury them , fry for 6 minutes, take out the sieve to remove the sand, let cool, and set aside;

[0057] 2) Polysaccharide extract of dog ridge: take hot dog ridge of uniform size, crush it through a 60-mesh sieve to obtain hot dog ridge powder, decoct it twice with 6 times the amount of water, 40 minutes each time, and combine the decoction liquid , concentrated under reduced pressure, added ethanol to make the final concentration 80%, kept overnight, and obtained crude p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com