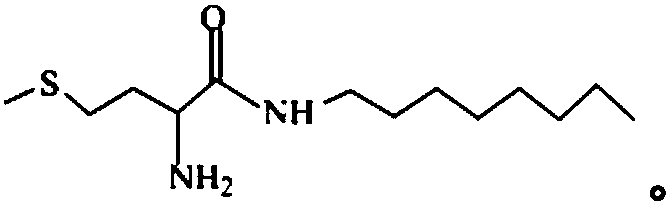

A kind of methionine derivative corrosion inhibitor for iron and steel pickling and its synthesis method

A synthesis method and methionine technology are applied in the field of methionine derivative corrosion inhibitor and its synthesis, which can solve the problems of poor water solubility of the final product, and achieve the effects of good corrosion inhibition effect, good water solubility and strong adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

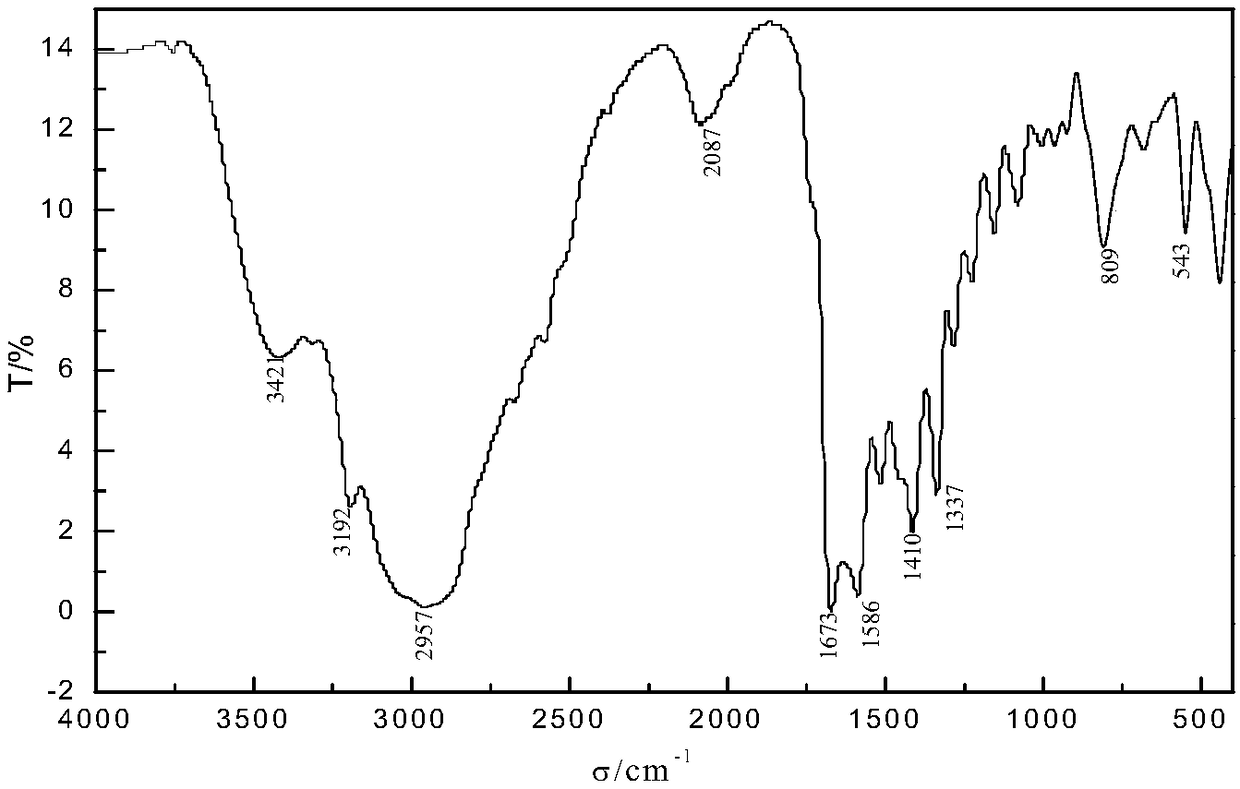

Method used

Image

Examples

preparation example Construction

[0026] 1) Preparation of thionyl chloride-methanol solution

[0027] Add 150mL of methanol to the reaction vessel, cool it in an ice-salt bath to below -10°C, and add 21.60mL of thionyl chloride dropwise under electromagnetic stirring. In order to avoid the chemical reaction between methanol and thionyl chloride, the dropping rate should be controlled The reaction temperature did not exceed 0°C, and after 1 hour of reaction, it was naturally raised to room temperature to obtain 150 mL of 2 mol / L thionyl chloride-methanol solution. Transfer the above solution to a brown reagent bottle, seal it, and store it away from light.

[0028] 2) Synthesis of methionine methyl ester hydrochloride

[0029] Install a reflux condenser, a dropping funnel and a thermometer on the three-necked container. Add 50mL of methanol into the reaction bottle, cool it to below -10°C with an ice-salt bath, slowly add 3.6mL of thionyl chloride dropwise under stirring, control the dropping speed and react...

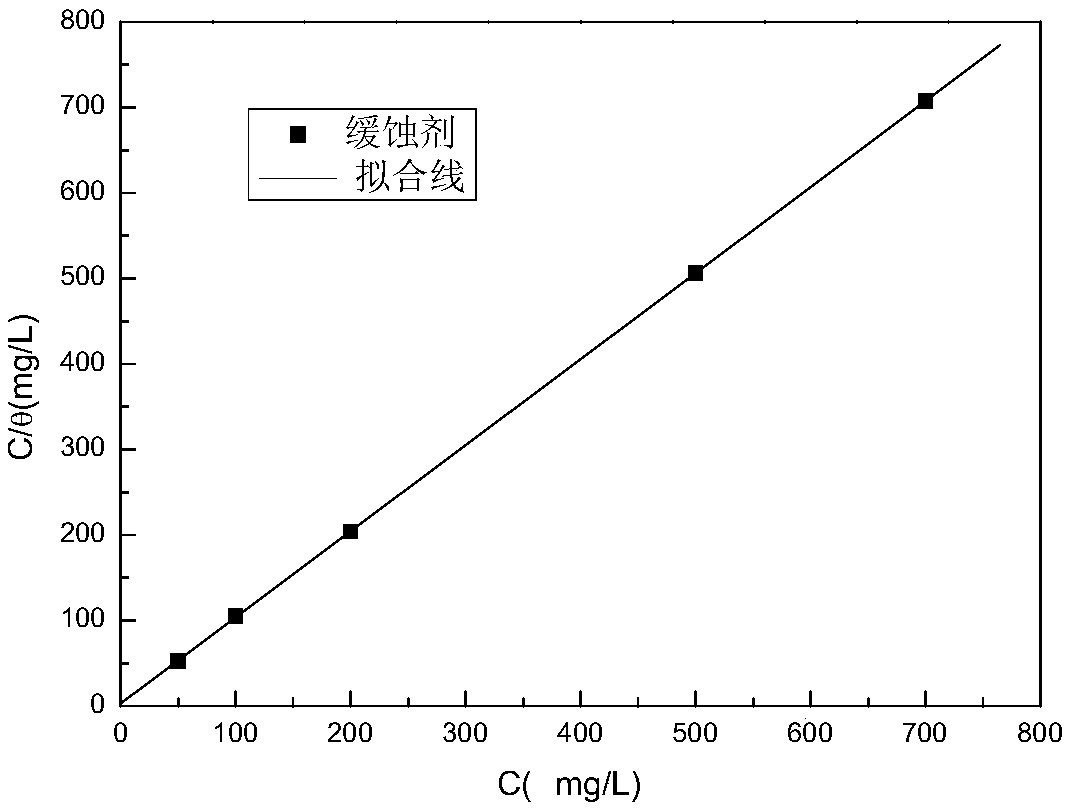

Embodiment 1

[0039] The pickling solution is 0.5mol / L sulfuric acid, and the pickling temperature is 30°C. Add 2-amino-3-methylthio-N-octyl-butyramide to the pickling solution, and the concentration of corrosion inhibitor added to each liter of pickling solution is 50mg / L. Immerse the carbon steel sheet in the pickling solution After 8 hours, after the experiment, remove the carbon steel sheet, clean the surface, dry it with cold air, and calculate the corrosion inhibition rate.

[0040] Conclusion: The calculated corrosion inhibition rate is 95%, indicating that the corrosion inhibitor has a good corrosion inhibition effect.

Embodiment 2

[0042] The pickling solution is 0.5mol / L sulfuric acid, and the pickling temperature is 30°C. Add 2-amino-3-methylthio-N-octyl-butyramide to the pickling solution, and the concentration of corrosion inhibitor added in each liter of pickling solution is 100mg / L. Immerse the carbon steel sheet in the pickling solution After 8 hours, after the experiment, remove the carbon steel sheet, clean the surface, dry it with cold air, and calculate the corrosion inhibition rate.

[0043] Conclusion: The calculated corrosion inhibition rate is 98%, which shows that the corrosion inhibitor has a good corrosion inhibition effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com