High-performance environment-friendly rubber dispersing agent

An environmentally friendly rubber and dispersant technology, applied in the field of dispersants, can solve the problems of water environment pollution, low biodegradation rate, incomplete degradation, etc., and achieve the effects of reducing pollution, reducing the impact on the human body, and strengthening environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

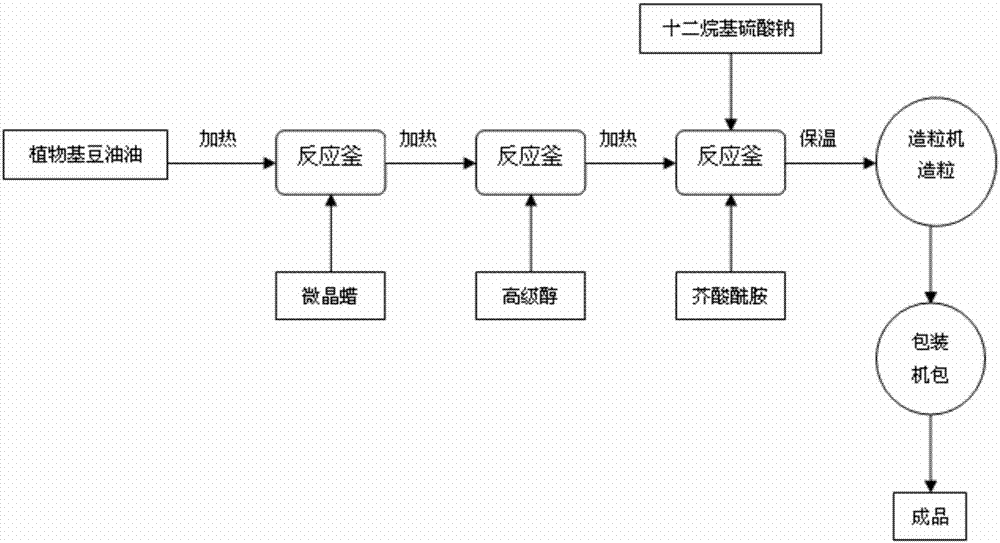

[0045] A kind of high-performance environment-friendly rubber dispersant provided by this embodiment has a structure such as figure 1 As shown, the raw materials of the dispersant according to the formulation quality include: 200 kg of plant-based soybean oil oleic acid, 37.5 kg of sodium lauryl sulfate, 77.5 kg of higher alcohol, 160 kg of erucamide, and 25 kg of microcrystalline wax.

[0046]The higher alcohol is a solid fatty alcohol mixture of cetyl alcohol and stearyl alcohol, and the solid fatty alcohol of cetyl alcohol: the solid fatty alcohol of stearyl alcohol = 2:1 by mass ratio.

[0047] The preparation method of above-mentioned high-performance environment-friendly dispersant comprises the following steps:

[0048] Step (1): First put 200kg of vegetable-based soybean oil into a 1000L stainless steel reactor, start the stirring paddle and turn on the steam heating to ensure that the soybean oil is completely melted in the reactor;

[0049] Step (2): When the temper...

Embodiment 2

[0055] A kind of high-performance environment-friendly rubber dispersant provided by the present embodiment, this dispersant comprises according to the raw material of formula quality: 207.5kg of plant-based soybean oil oleic acid, 45 kg of sodium lauryl sulfate, 70 kg of higher alcohol, 152.5 kg of erucamide kg, microcrystalline wax: 25 kg.

[0056] The higher alcohol is a solid fatty alcohol mixture of cetyl alcohol and stearyl alcohol, and the solid fatty alcohol of cetyl alcohol: the solid fatty alcohol of stearyl alcohol = 2:1 by mass ratio.

[0057] A preparation method of a novel high-performance environment-friendly dispersant, comprising the following steps:

[0058] Step (1): First put 207.5kg of vegetable-based soybean oil into a 1000L stainless steel reactor, start the stirring paddle and turn on the steam heating to ensure that the soybean oil is completely melted in the reactor;

[0059] Step (2): When the temperature of the reactor reaches 60-70°C, control the ...

Embodiment 3

[0065] A kind of high-performance environment-friendly rubber dispersant provided in this embodiment, the raw material of this dispersant according to formula quality comprises: plant-based soybean oil oleic acid 190 kg, sodium lauryl sulfate 40 kg, higher alcohol 72.5 kg, erucamide 175 kg kg, microcrystalline wax: 22.5 kg.

[0066] The higher alcohol is a solid fatty alcohol mixture of cetyl alcohol and stearyl alcohol, and the solid fatty alcohol of cetyl alcohol: the solid fatty alcohol of stearyl alcohol = 2:1 by mass ratio.

[0067] A preparation method of a novel high-performance environment-friendly dispersant, comprising the following steps:

[0068] Step (1): First put 190kg of plant-based soybean oil into a 1000L stainless steel reactor, start the stirring paddle and turn on the steam heating to ensure that the soybean oil is completely melted in the reactor;

[0069] Step (2): When the temperature of the reactor reaches 60-70°C, control the steam to continue heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com