Double-component mould-proof silane-modified polyether gum and preparation method thereof

A anti-mildew silane, two-component technology, applied in the direction of polyether adhesives, adhesives, polymer adhesive additives, etc., can solve problems such as failure, easy decomposition of environmental temperature changes, unstable structure of anti-mold agents, etc. achieve good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

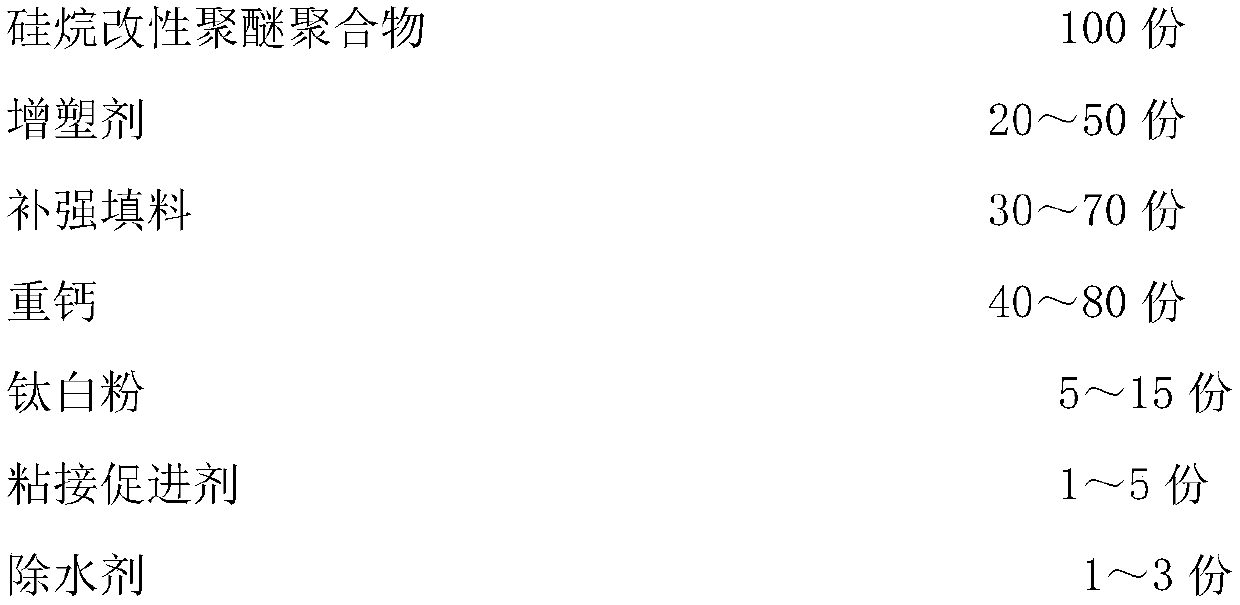

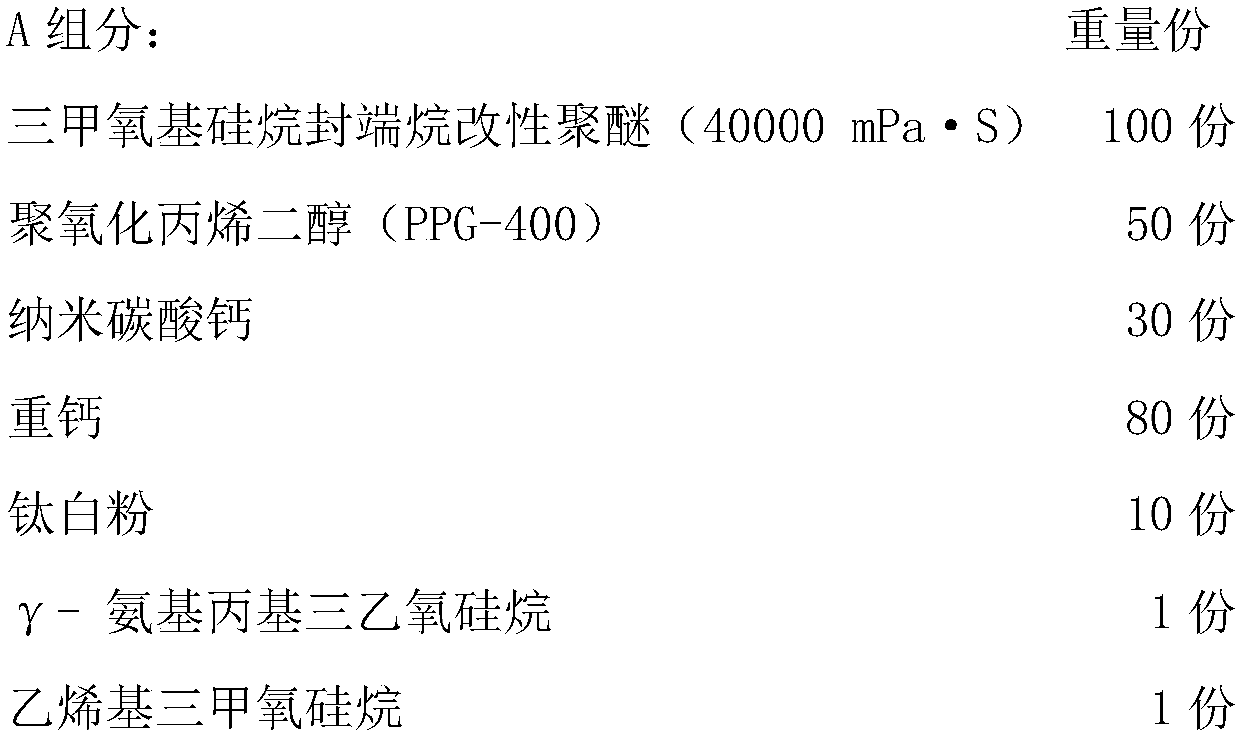

[0035] The two-component antifungal glue described in this embodiment is specifically prepared according to the following proportions by weight:

[0036]

[0037] B component:

[0038]

[0039] The two-component antifungal glue described in this embodiment is specifically prepared according to the following process:

[0040] Preparation of component A:

[0041] First, put the amount of PPG-400, nano-calcium carbonate, heavy calcium, and titanium dioxide into the kneader, at a temperature of 110 ° C, pump to a vacuum of 0.08 MPa, dehydrate and knead for 120 minutes, cool to room temperature, and discharge to obtain the base material.

[0042] Put the base material and silane-modified polyether into the planetary mixer according to the amount, and stir and mix for 10 minutes. Then add vinyltrimethoxysilane according to the amount, evacuate to a vacuum of 0.08MPa, and stir and mix for 5 minutes. Release the vacuum, then add γ-aminopropyltriethoxysilane according to the a...

Embodiment 2

[0047]

[0048] B component:

[0049]

[0050] The two-component antifungal glue described in this embodiment is specifically prepared according to the following process:

[0051] Preparation of component A:

[0052] First, put the amount of PPG-400, white carbon black, heavy calcium, and titanium dioxide into the kneader, at a temperature of 130 ° C, pump to a vacuum of 0.09 MPa, dehydrate and knead for 150 min, cool to room temperature, and discharge to obtain the base material.

[0053]Put the base material and silane-modified polyether into the planetary mixer according to the amount, and stir and mix for 15 minutes. Then add vinyltriethoxysilane according to the amount, evacuate to a vacuum of 0.09MPa, and stir and mix for 5 minutes. Release the vacuum, then add γ-aminopropyltrimethoxysilane according to the amount, evacuate to a vacuum degree of 0.08MPa, stir and mix for 15min, and obtain component A.

[0054] Preparation of component B:

[0055] First weigh de...

Embodiment 3

[0058]

[0059] B component:

[0060]

[0061] The two-component antifungal glue described in this embodiment is specifically prepared according to the following process:

[0062] Preparation of component A:

[0063] First, put the amount of PPG-600, nano-calcium carbonate, heavy calcium, and titanium dioxide into the kneader, at a temperature of 120°C, pump to a vacuum of 0.09MPa, dehydrate and knead for 130min, cool to room temperature, and discharge to obtain the base material.

[0064] Put the base material and silane-modified polyether into the planetary mixer according to the amount, and stir and mix for 10 minutes. Then add vinyltriethoxysilane according to the amount, evacuate to a vacuum of 0.09MPa, and stir and mix for 10min. Release the vacuum, then add N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane according to the amount, evacuate to a vacuum degree of 0.08MPa, stir and mix for 20min to obtain component A.

[0065] Preparation of component B:

[0066] Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com