Preparation method of graphene functional aviation tire

A technology of aviation tires and graphene, applied in special tires, tire parts, rolling resistance optimization, etc., can solve the problems of difficult dispersion and difficulty in adding conductive media, and achieve the effects of easy dispersion, uniform stress, and convenient addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

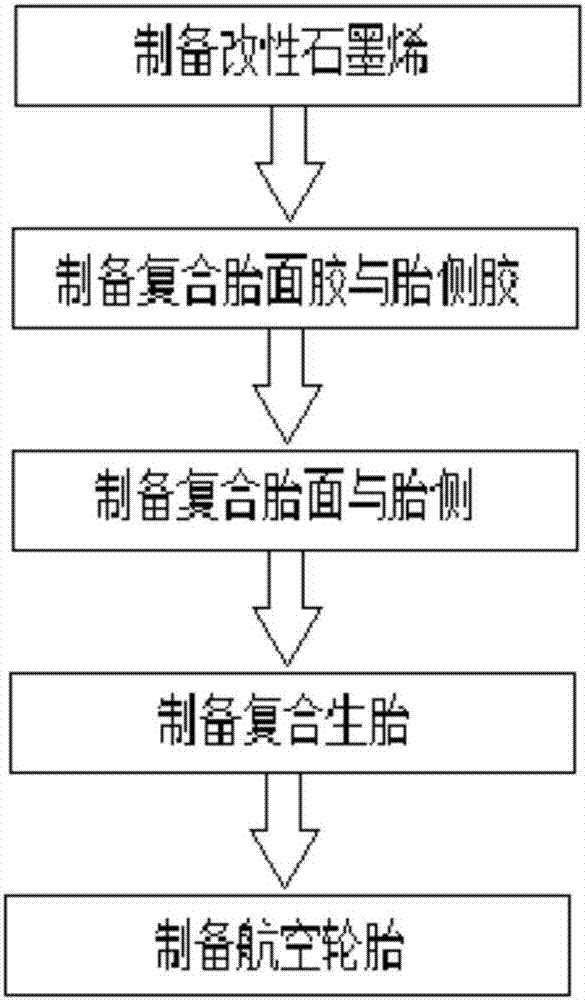

[0017] The technical process of the graphene functional aviation tire preparation method involved in this embodiment includes the preparation of modified graphene, the preparation of composite tread rubber and sidewall rubber, the preparation of composite tread and sidewall, the preparation of composite raw tires, and the preparation of aviation tires. steps:

[0018] (1) Preparation of modified graphene: successively add 1 mass part of graphite and 1 mass part of strong oxidant in the reactor, graphite and strong oxidant form a mixed material, start the reactor, when the color of the mixed material becomes golden yellow , close the reaction kettle, take out the mixed material and carry out drying and high-temperature reduction to obtain modified graphene, and complete the preparation of modified graphene;

[0019](2) Preparation of composite tread rubber and sidewall rubber: respectively adding the modified graphene prepared by 0.1 parts by mass of step (1) to the tread rubbe...

Embodiment 2

[0025] The technical process of the graphene functional aviation tire preparation method involved in this embodiment includes the preparation of modified graphene, the preparation of composite tread rubber and sidewall rubber, the preparation of composite tread and sidewall, the preparation of composite raw tires, and the preparation of aviation tires. steps:

[0026] (1) Preparation of modified graphene: successively add 5 mass parts of graphite and 20 mass parts of strong oxidant in the reactor, graphite and strong oxidant form a mixed material, start the reactor, when the color of the mixed material becomes golden yellow , close the reaction kettle, take out the mixed material and carry out drying and high-temperature reduction to obtain modified graphene, and complete the preparation of modified graphene;

[0027] (2) Preparation of composite tread rubber and sidewall rubber: after adding the modified graphene prepared by 15 parts by mass of step (1) to the tread rubber an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com