Sliding component and method

A technology of sliding parts and particles, applied in the direction of anti-centrifugal rotating parts, engine components, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

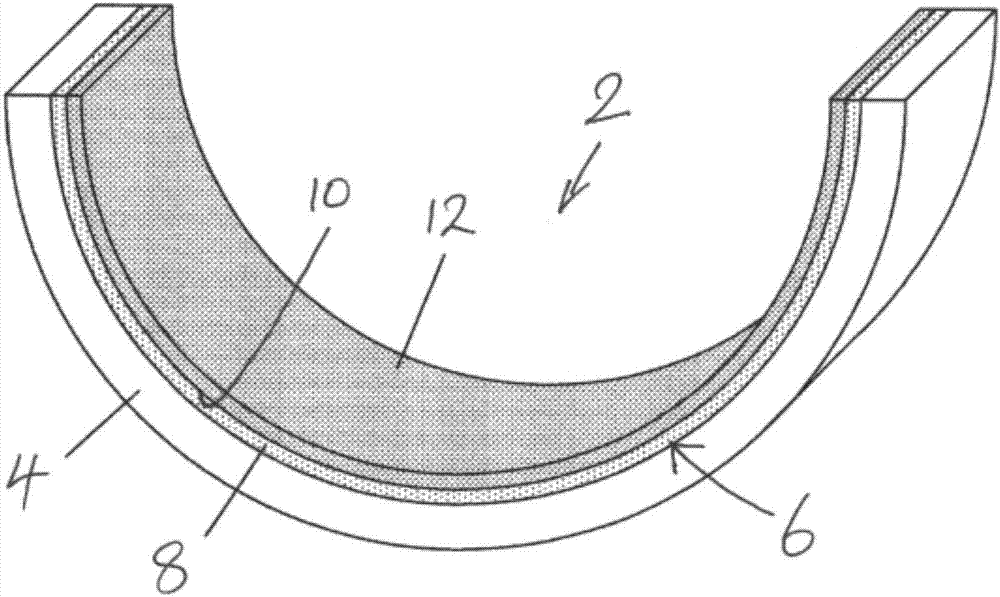

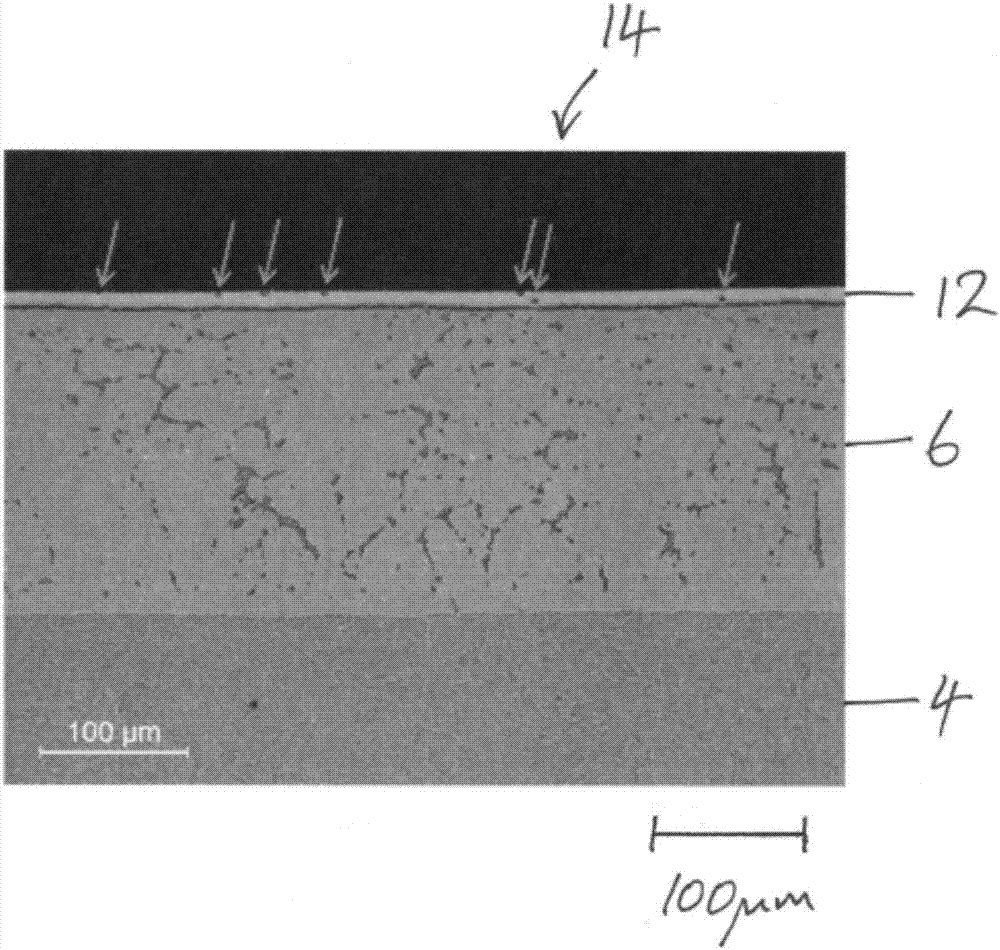

[0035] figure 1 Shown is a half-bearing, or half-cylindrical bearing shell 2 , of a main bearing assembly of an internal combustion engine for holding a cylindrical journal of a crankshaft. The bearing half includes a half-cylindrical bearing shell. The bearing shell has a layered structure incorporating a steel backing 4 . The backing is coated or bonded to a liner layer 6 comprising a copper-tin bronze and nickel diffused film, or layer 8 of the intermediate layer 10 . The coating 12 is formed by electroplating on the intermediate layer.

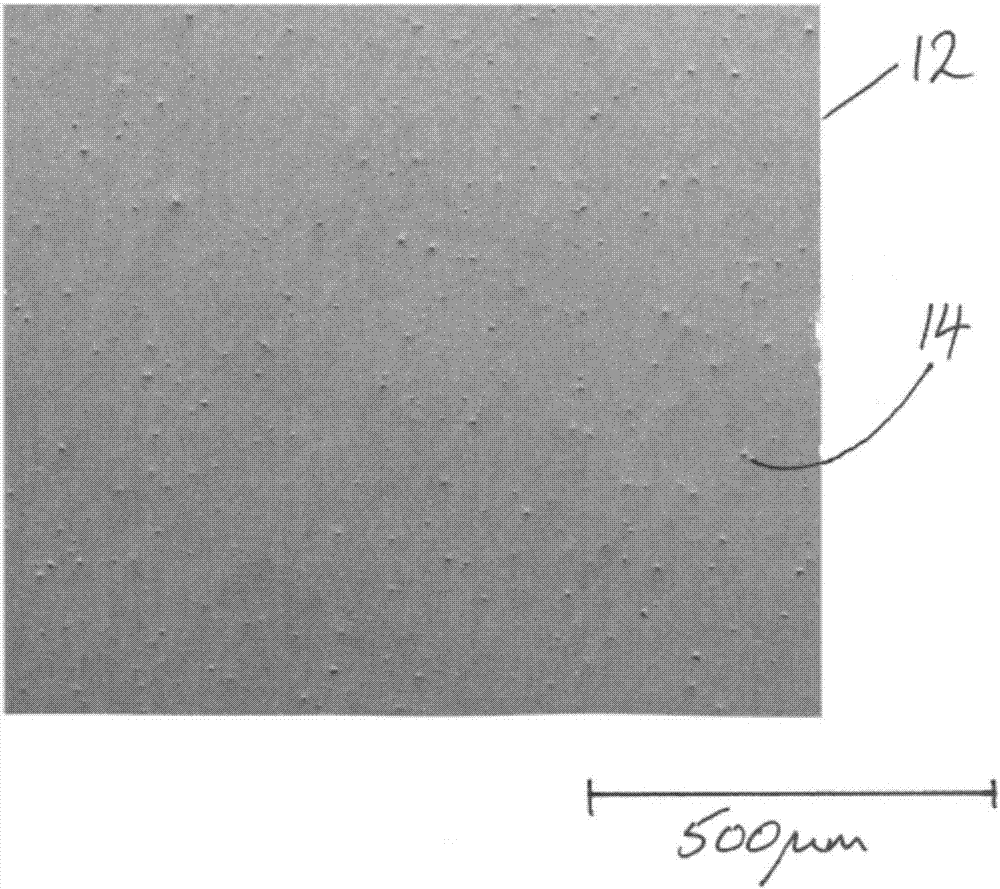

[0036] Coatings include Ni in a tin matrix 3 particles of Al, the tin matrix is formed by electroplating on the intermediate layer. The intermediate layer is arranged as a cathode in a bath containing a plating electrolyte and an anode, and a cathode bias (ie, a negative bias) is applied to the cathode relative to the anode. The cathode bias drives the positively charged metal ions, such as tin, towards the cathode and deposits the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| interface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com