Titanium and titanium alloy electrochemical polishing liquid and polishing method

A technology of electrochemistry and polishing liquid, applied in the direction of electrolysis process, electrolysis components, etc., to achieve the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for electrochemical polishing of titanium and titanium alloy workpieces, comprising the steps in turn:

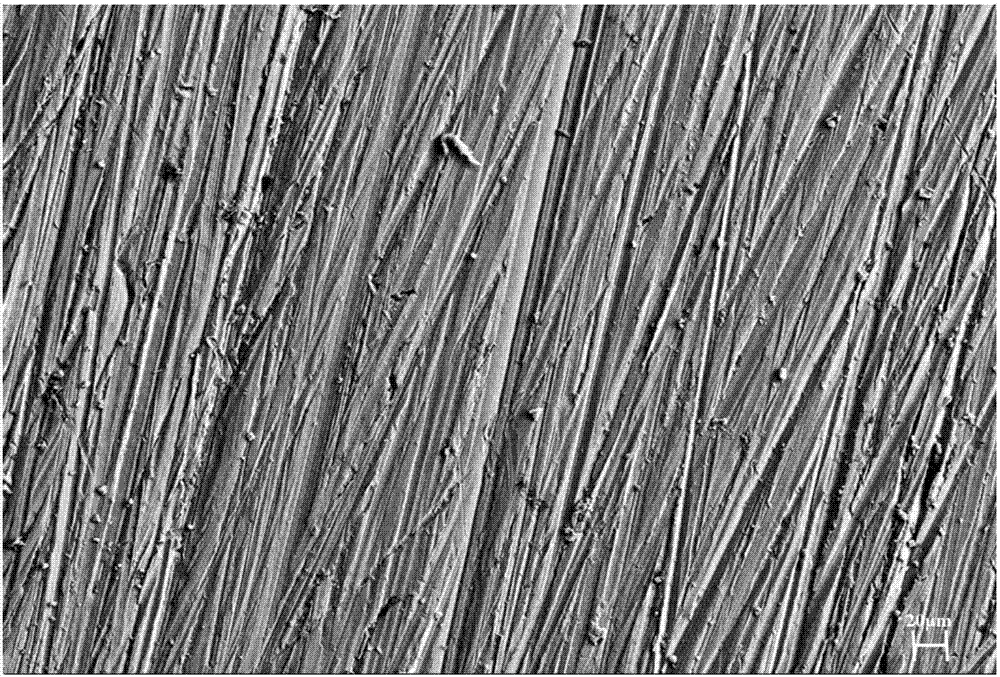

[0051] (1) Polish the titanium alloy workpiece with metallographic sandpaper of 400 mesh, 600 mesh, 800 mesh, 1000 mesh and 1200 mesh in sequence, and ultrasonically clean the workpiece in the order of deionized water, acetone, absolute ethanol and deionized water after polishing ;

[0052] (2) According to HF: HNO 3 :H 2 The volume ratio of O is 3:10:87 to prepare a mixed acid solution, soak the workpiece in the acid solution for 1min, take it out, rinse it with deionized water and dry it;

[0053] (3) Using glycerin as a solvent, measure 400mL of glycerin, add 400ml of ethylene glycol, 200mL of ethanol, 1mL of perchloric acid, 40g of sodium chloride, 1g of citric acid, 0.5g of glucose and 0.5g of urea in sequence under stirring, and stir evenly Obtain an electrolytic polishing solution;

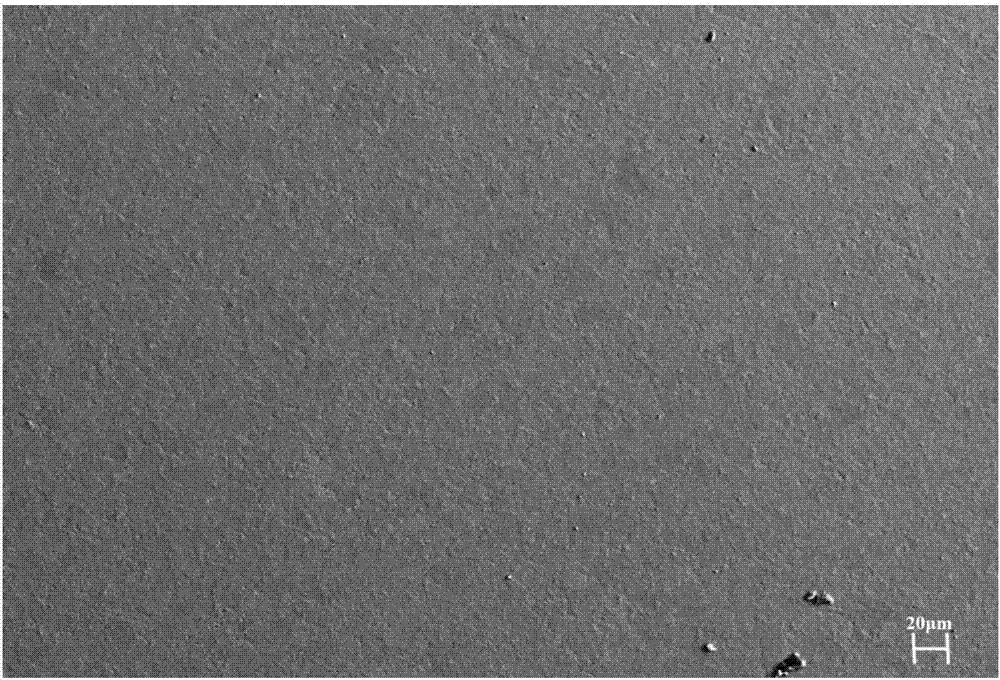

[0054] (4) Fully immerse the titanium alloy workpiece in the ele...

Embodiment 2

[0058] A method for electrochemical polishing of titanium and titanium alloy workpieces, comprising the steps in turn:

[0059] (1) Polish the titanium metal workpiece with 400 mesh, 600 mesh, 800 mesh, 1000 mesh and 1200 mesh metallographic sandpaper in sequence. After polishing, perform ultrasonic cleaning on the workpiece in the order of deionized water, acetone, absolute ethanol and deionized water ;

[0060] (2) According to HF: HNO 3 :H 2 The volume ratio of O is 3:10:87 to prepare a mixed acid solution, soak the workpiece in the acid solution for 1min, take it out, rinse it with deionized water and dry it;

[0061] (3) Using glycerin as a solvent, measure 400mL of glycerin, add 400ml of ethylene glycol, 200mL of ethanol, 1mL of perchloric acid, 40g of sodium chloride, 1g of citric acid, 0.5g of glucose and 0.5g of urea in sequence under stirring, and stir evenly Obtain an electrolytic polishing solution;

[0062] (4) Fully immerse the titanium metal workpiece in the...

Embodiment 3

[0066] A method for electrochemical polishing of titanium and titanium alloy workpieces, comprising the steps in turn:

[0067] (1) Polish the titanium alloy workpiece with metallographic sandpaper of 400 mesh, 600 mesh, 800 mesh, 1000 mesh and 1200 mesh in sequence, and ultrasonically clean the workpiece in the order of deionized water, acetone, absolute ethanol and deionized water after polishing ;

[0068] (2) According to HF: HNO 3 :H 2 The volume ratio of O is 3:10:87 to prepare a mixed acid solution, soak the workpiece in the acid solution for 1min, take it out, rinse it with deionized water and dry it;

[0069] (3) Using glycerin as a solvent, measure 700 mL of glycerin, add 250 mL of ethylene glycol, 50 mL of ethanol, 10 mL of perchloric acid, 15 g of sodium chloride, 1 g of tartaric acid, 0.5 g of sulfamic acid and 0.5 g of glucose in sequence under stirring, and stir Obtain electrolytic polishing liquid evenly;

[0070] (4) Fully immerse the titanium alloy workpi...

PUM

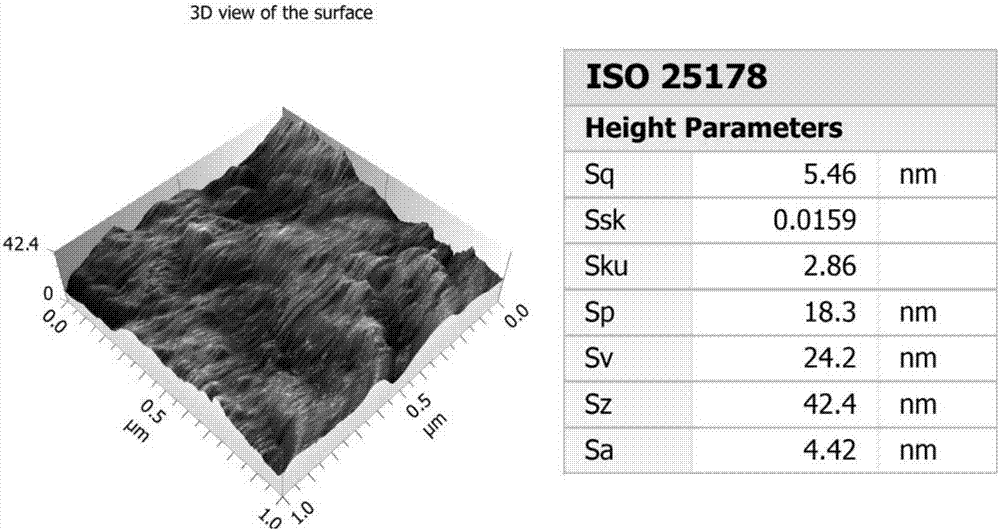

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com