Efficient low-foam refining agent and preparation method thereof

A refining agent and high-efficiency technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of difficult elimination of foam, high metal ion content, easy anti-sticking, insufficient refining, etc., to achieve good whiteness, good capillary effect, sensitive low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

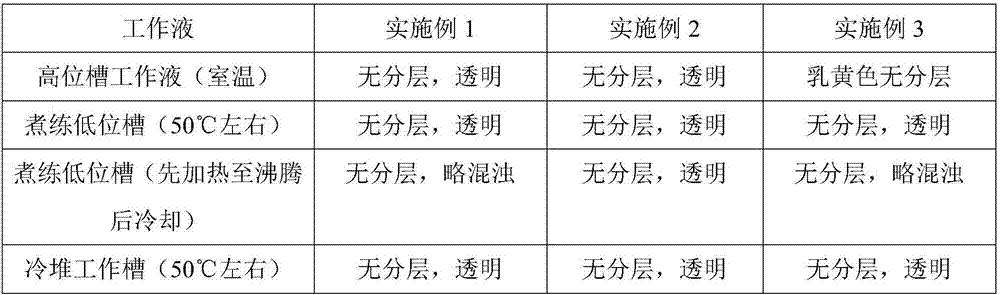

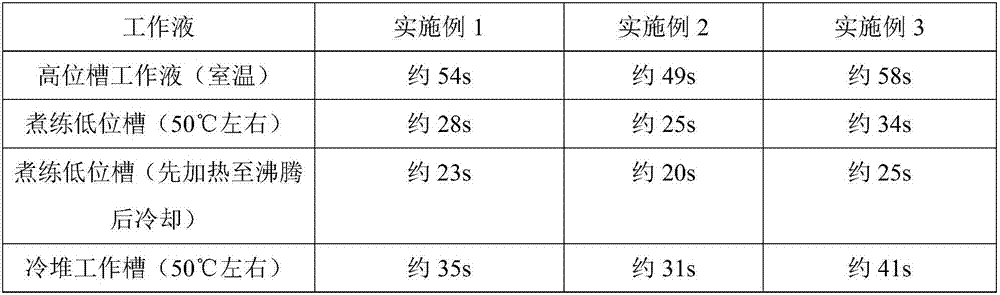

Embodiment 1

[0023] Scouring agent components:

[0024] 30 parts of didodecanyl polyglucoside (DP=1.8), 2 parts of isohexyl alcohol polyoxypropylene polyoxyethylene ether (3EO0.8PO), 4 parts of sodium polyacrylate, 8 parts of decane diphenyl ether disulfonate, The balance is water, 100 parts in total.

[0025] Preparation method of scouring agent:

[0026] A method for preparing a high-efficiency low-foaming refining agent. First, 30 parts of didodecanyl polyglucoside (DP=1.8) are slowly added to 50 parts of water, and stirred rapidly. After the solution is completely dissolved, the temperature of the solution is raised to 50°C; Slowly add 2 parts of isohexyl alcohol polyoxypropylene polyoxyethylene ether (3EO0.8PO) and stir for 30 minutes; finally add 4 parts of sodium polyacrylate and 8 parts of decane diphenyl ether disulfonate, stir well and cool to room temperature , and slowly make up the remaining water to obtain a light yellow transparent liquid.

Embodiment 2

[0028] Scouring agent components:

[0029] 35 parts of didodecanyl polyglucoside (DP=1.5), 5 parts of isooctyl alcohol polyoxypropylene polyoxyethylene ether (3EO1PO), 2 parts of sodium polyacrylate, 12 parts of dodecyl diphenyl ether disulfonate , and the balance is water, a total of 100 parts.

[0030] Preparation method of scouring agent:

[0031] A method for preparing a high-efficiency low-foaming refining agent. First, 35 parts of didodecanyl polyglucoside (DP=1.5) are slowly added to 40 parts of water, and stirred rapidly. After the solution is completely dissolved, the temperature of the solution is raised to 50°C; Slowly add 5 parts of isopolyoxypropylene polyoxyethylene ether (3EO1PO) and stir for 30 minutes; finally add 2 parts of sodium polyacrylate and 12 parts of dodecyl diphenyl ether disulfonate, stir evenly and cool to room temperature. Slowly make up the remaining water to obtain light yellowish brown transparent liquid.

Embodiment 3

[0033] Scouring agent components:

[0034] 32 parts of didodecanyl polyglucoside (DP=1.6), 3.5 parts of isooctyl alcohol polyoxypropylene polyoxyethylene ether (3EO1.2PO), 3 parts of sodium polyacrylate, undecyl diphenyl ether disulfonate 10 parts, the balance is water, a total of 100 parts.

[0035] Preparation method of scouring agent:

[0036] A method for preparing a high-efficiency low-foaming refining agent. First, 32 parts of didodecanyl polyglucoside (DP=1.6) are slowly added to 50 parts of water, and stirred rapidly. After the solution is completely dissolved, the temperature of the solution is raised to 50°C; Slowly add 3.5 parts of isooctyl alcohol polyoxypropylene polyoxyethylene ether (3EO1.2PO) and stir for 30 minutes; finally add 3 parts of sodium polyacrylate and 10 parts of undecyl diphenyl ether disulfonate, stir well and cool to Room temperature is sufficient, and the remaining water is slowly replenished to obtain a light yellow-brown transparent liquid. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com