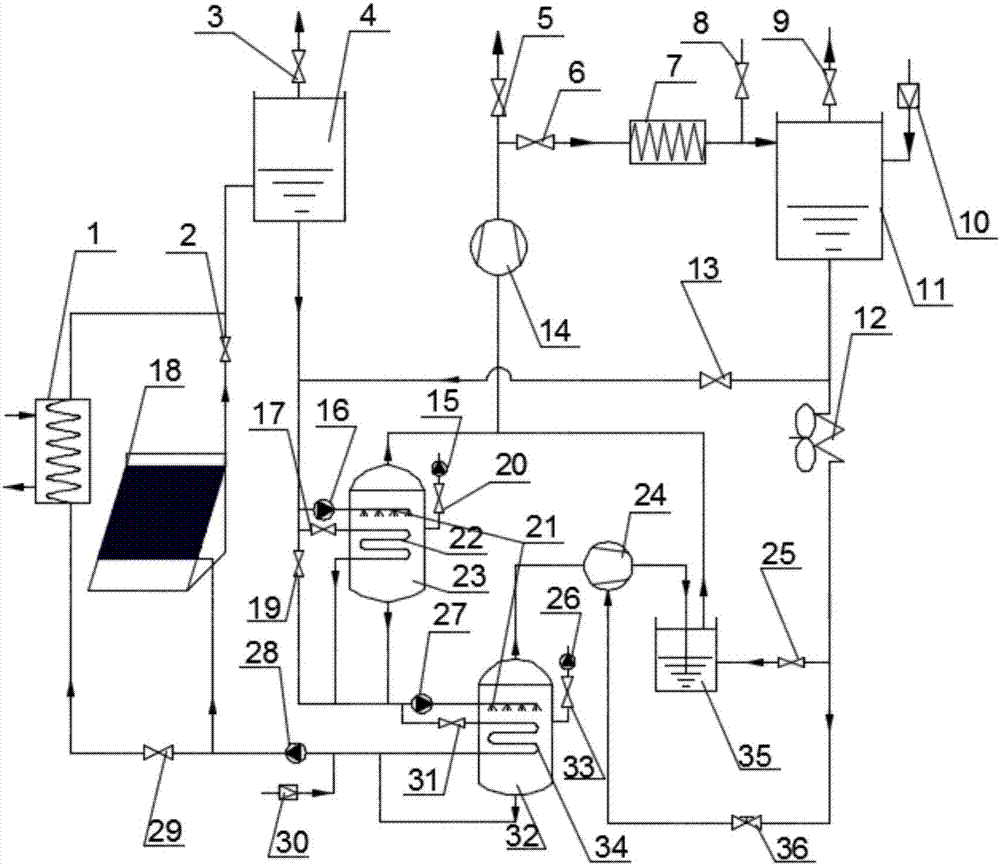

Two-stage flash evaporation and two-stage compression heat pump device with double heat sources and operating method

A two-stage flash evaporation and two-stage compression technology, applied in the field of energy and heat pumps, can solve the degradation of heat quality (the obtained steam temperature is much lower than the 190 ℃ condensate temperature, the heat pump technology has a low condensation temperature, and low-grade heat recovery. Insufficient efficiency and other problems, to achieve the effect of large heat release, high energy efficiency, energy saving and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, characteristics and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] Furthermore, the directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "top", etc. , is only for reference to the direction of the attached drawing. Therefore, the use of directional terms is used to illustrate and understand the present invention, but not to limit the present invention.

[0037] Such as figure 1 As shown, it is a two-stage flash two-stage compression heat pump device with dual heat sources according to an embodiment of the present invention, including four parts: a heat collection system, a primary flash system, a secondary flash system, and a vapor compression system. The heat collection system includes: a first replenishment val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com