Multipoint zoning sampling system and method for monitoring multiphase flow medium ingredient

A partitioned sampling and multi-phase flow technology, applied in sampling, sampling device, test sample preparation, etc., can solve problems such as easy blockage of samplers, low representativeness of single-point sampling, large deviation of measurement results, etc., to achieve Ensure long-term use, reduce operation and equipment maintenance costs, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

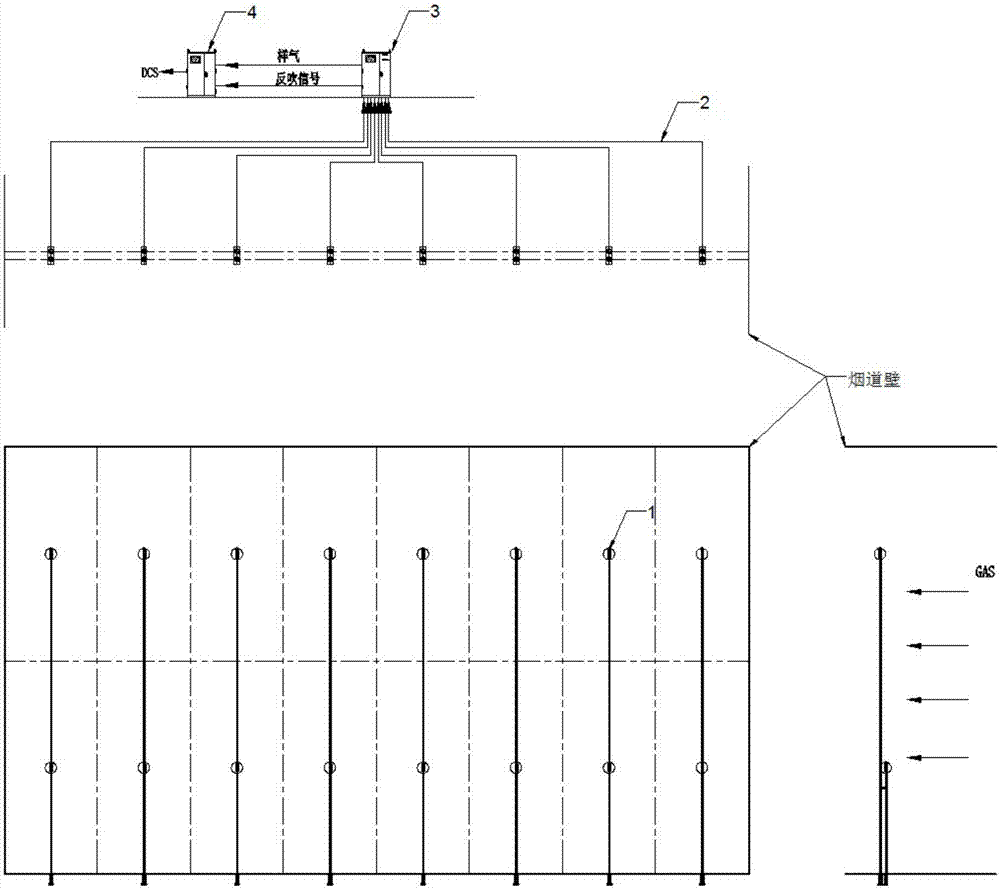

[0031] Embodiment 1: as figure 1 The shown multi-point partition sampling system for monitoring the composition of multiphase flow media includes a sampling unit 1, a high-temperature heat tracing pipeline 2, a control cabinet 3, and a medium analysis cabinet 4; the sampling unit 1 includes sixteen sampler components (according to The size of the specific flue can be increased or decreased by the sampler assembly).

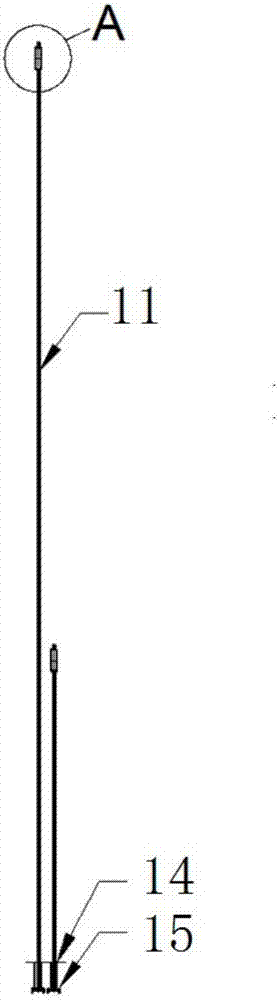

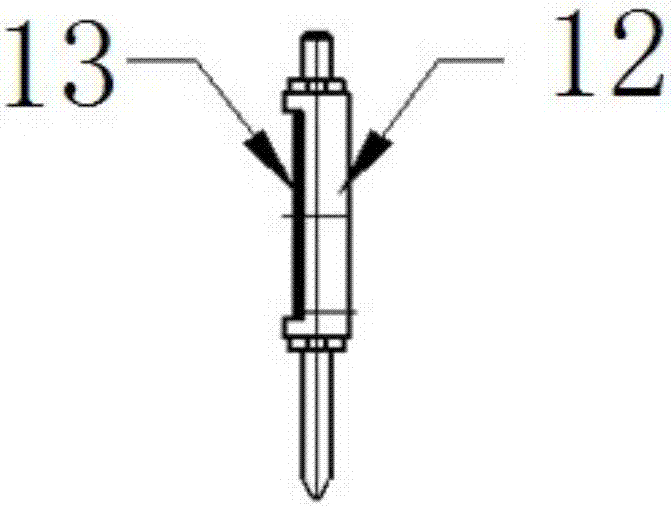

[0032] like figure 2 , image 3 The shown sampler assembly comprises a sampling gun barrel 11, a protective shell 12, a filter core 13, a welding flange 14, and a bolt 15; the welding flange 14 is welded on the flue wall, and the tail end of the sampling gun barrel 11 passes through the bolt 15 and The welding flange 14 is connected, and the outlet end opposite to the tail end is provided with an internal threaded hole, which is used to install a hose quick-twist joint and connect with the high-temperature heat tracing pipeline 2; the sampling gun barrel 11 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com