Multilayered composite material and objects comprising same

A composite and polymer material technology, applied in the direction of transportation and packaging, packaging item types, special packaging items, etc., can solve the problems of copolymer processability and flexibility decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

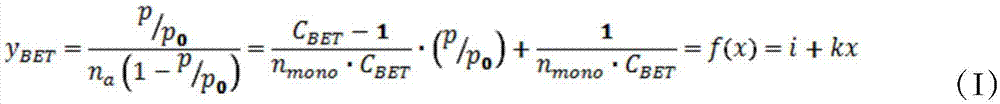

Method used

Image

Examples

Embodiment 1

[0097] Example 1. Production of test panels with and without adsorbent material

[0098] Aperture is [0.4 nm] molecular sieves, such as BASF Molekularsieb 4A (BASF, Ludwigshafen, Germany), and metal-organic frameworks based on aluminum fumarate known under the trade name Basolite A520 (BASF, Ludwigshafen, Germany) , used as an adsorbent material. The synthesis of such metal-organic frameworks is described, for example, in WO 2012 / 042410 A1.

[0099] The spherical adsorbent material was manually pulverized in a laboratory mortar. The ground material is passed through an analytical sieve having a wire mesh according to DIN ISO 3310-1:2001 and a mesh opening of 500 μm. The sieved fraction was used for subsequent blending with polymer. The obtained powdered adsorbent material is used directly for mixing with polymers without prior manual comminution.

[0100] A mixture containing 10% by weight of the corresponding adsorbent material and 90% by weight of HPDE (Lupolen 4261AG ...

Embodiment 2

[0102] Example 2. Lamination of test panels with 5 layers of COEX material

[0103] A film produced by coextrusion and having a layer structure HDPE / adhesive / EVOH / adhesive / HDPE with a total thickness of 220 μm was used as a 5-layer COEX material, with two HDPE layers (Lupolen 4261AG) having a thickness of 90 μm in each case, the thickness of the two adhesive layers (Admer GT6, Mitsui Chemicals, Tokyo, Japan) was 10 μm in each case, and the thickness of the EVOH layer (EVAL F101A, Chiyoda Kuraray, Japan) was 20 μm.

[0104] By applying in each case a test plate as described in Example 1 to one side of the film and pressing the structure for 5 minutes at 190° C. and a pressure of 90 bar, followed by watering the sample press The resulting laminate was cooled to a temperature below 60° C. and the laminate was demoulded, and the 5-layer film was laminated to the test panels described in Example 1 in a Schwabenthan sample press.

[0105] This example shows that conventional lamin...

Embodiment 3

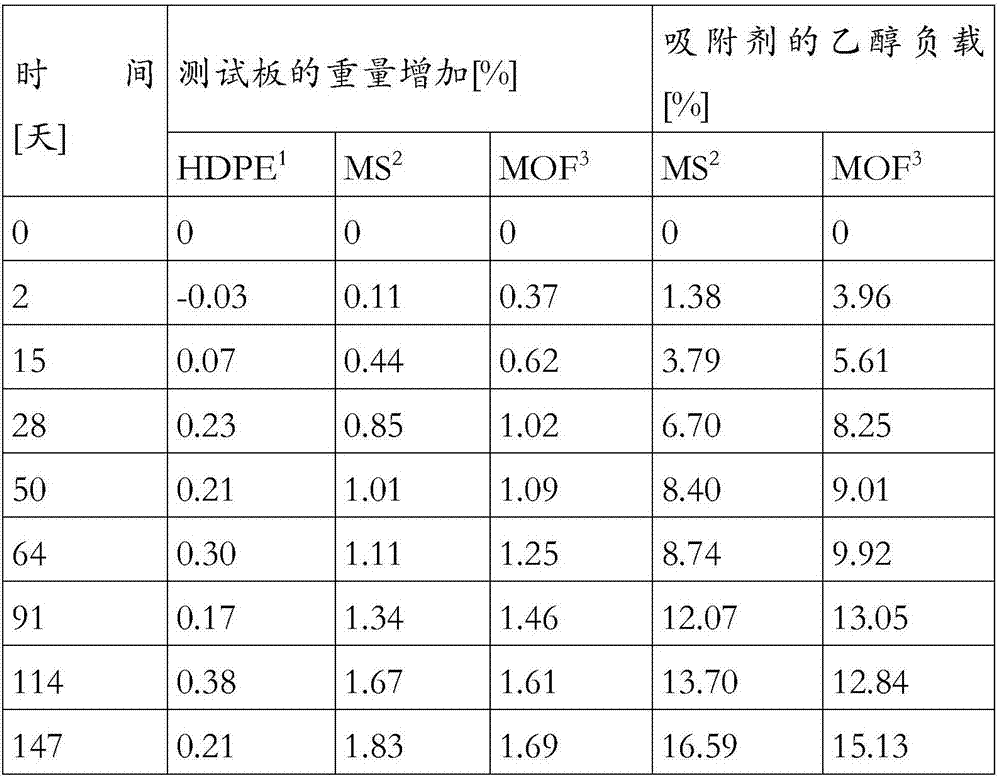

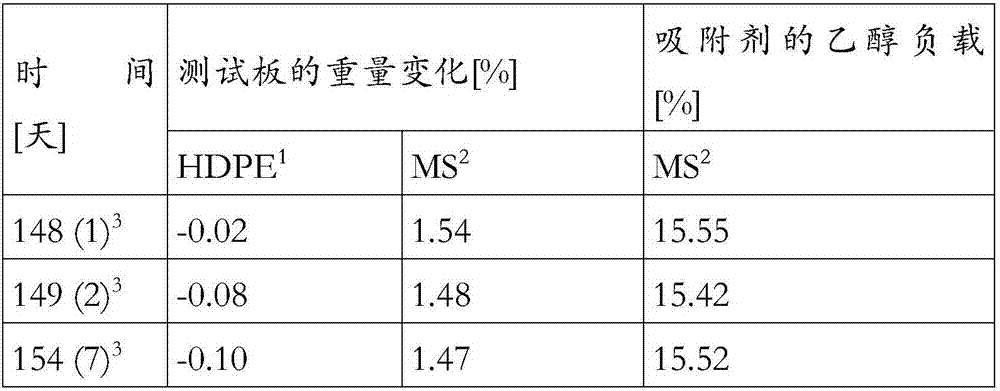

[0106] Example 3. Adsorption and desorption measurements

[0107] As comparative samples, test panels without added sorbent (called HPDE in Table 1) weighing approximately 20 g and consisting of pure HPDE (i.e. no laminated 5-layer film) and in each case added with 10 Test panels with molecular sieves described in Example 1 (referred to as MS in Table 1) or metal-organic frameworks (referred to as MOF in Table 1) as adsorbents in % by weight were produced as described in Example 1. These test panels were exposed to an atmosphere of gaseous ethanol at room temperature (approximately 20-23° C.) in a glass container. High-purity absolute ethanol (denatured with 1% methyl ethyl ketone), commercially available eg from VWR International GmbH (Darmstadt, Germany) under catalog number APPCA5007.2500, was used as alcohol. The weight gain was determined over a period of 147 days with the aid of a Sartorius 2007 MP6 analytical balance (Sartorius, Göttingen, Germany).

[0108] The perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com