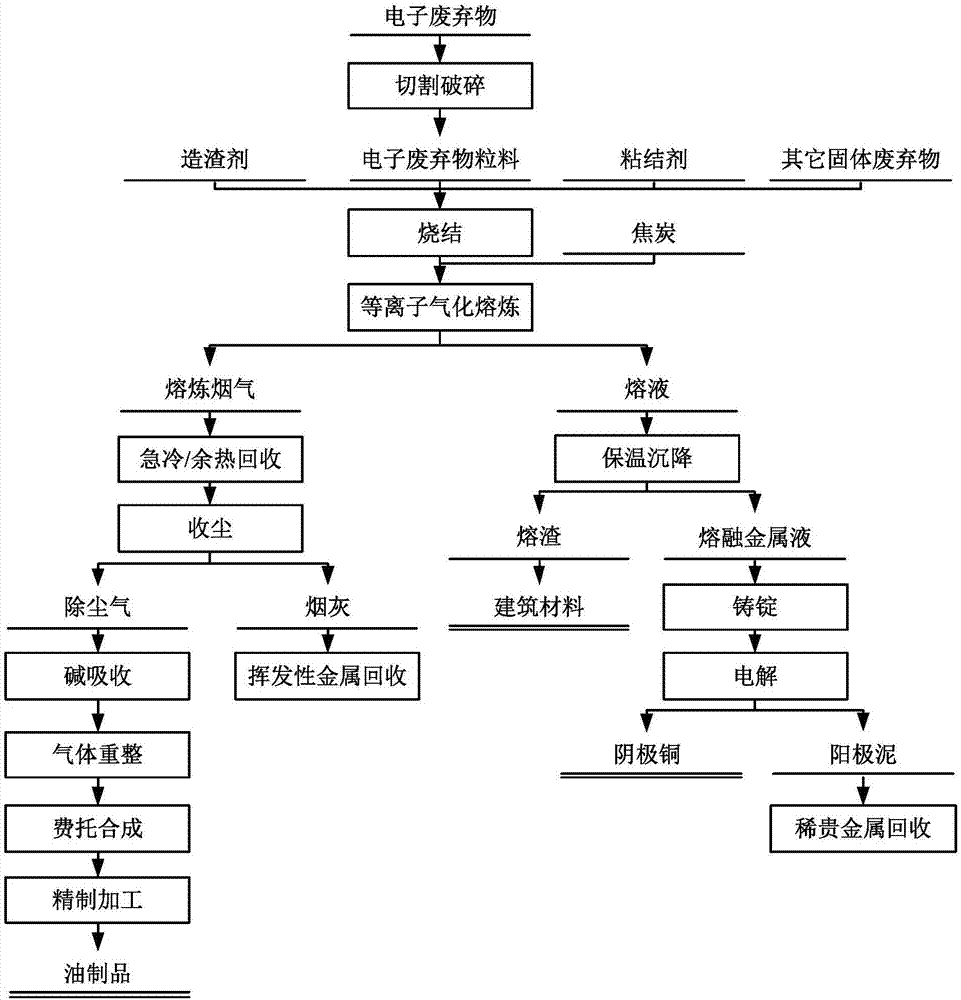

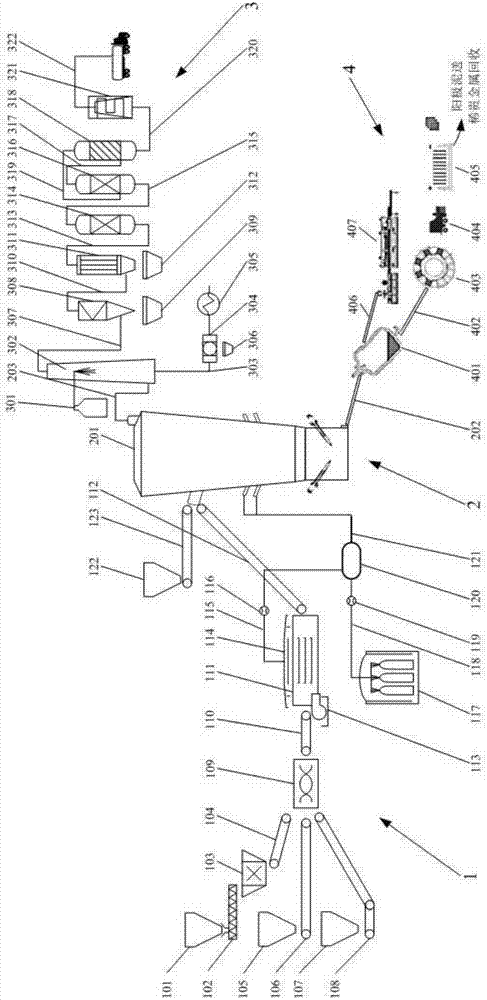

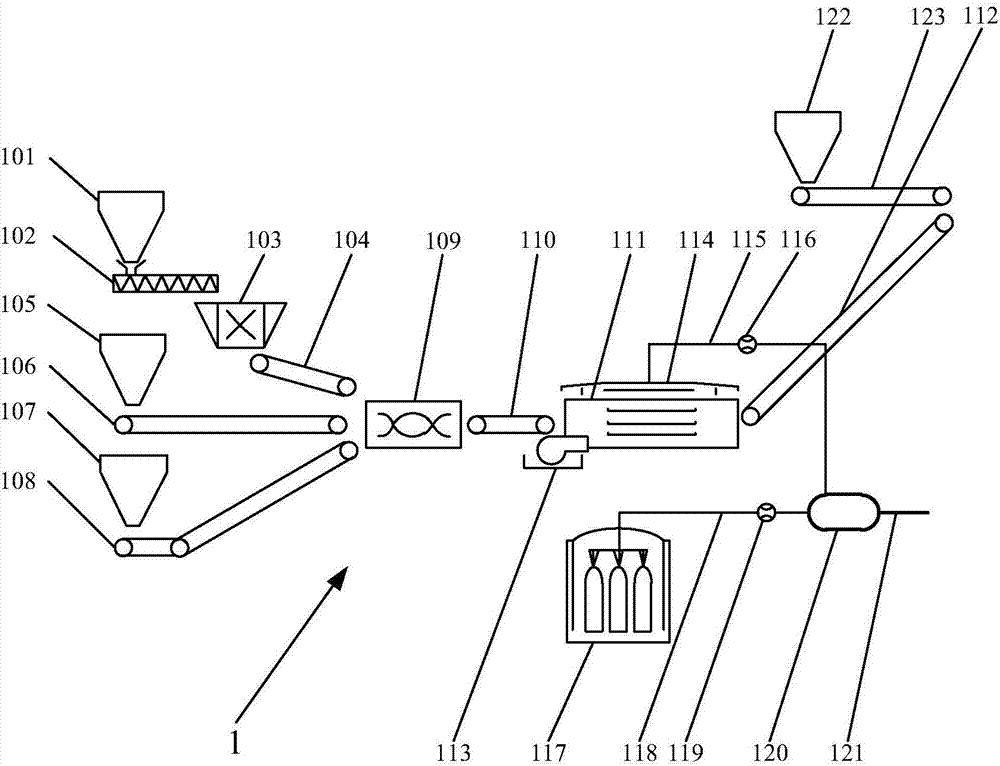

Comprehensive resourceful treatment system and method of electronic wastes

An electronic waste and comprehensive resource technology, applied in the field of electronic waste comprehensive resource treatment system, can solve the problems of low pyrolysis temperature, required vacuum environment, pipeline blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: A method for comprehensive recycling of electronic waste, comprising the following steps:

[0068] 1) Pellet sintering: first cut and crush the waste computer mainframe into electronic waste pellets with a particle size of 5-10mm, and then mix the electronic waste pellets with slagging agent and binder according to the mass ratio of 1:0.5: 0.1 Use N after uniform mixing 2 In the protected indirect heating sintering method, the sintering process is carried out at a temperature of 600°C to obtain agglomerates and generate sintering gas at the same time; among them, the slagging agent is limestone and quartz sand mixed in a mass ratio of 2:3, and the binder is soap. earth;

[0069] 2) Plasma gasification smelting: Alternately put the agglomerates and coke obtained in step 1) into the plasma gasification smelting furnace at a mass ratio of 1:0.7, so that the two are alternately arranged longitudinally in layers, and at the same time, the After the sintering ...

Embodiment 2

[0072] Embodiment 2: A method for comprehensive recycling of electronic waste, comprising the following steps:

[0073] 1) Pellet sintering: first cut and crush the discarded CRT TV mainboard into electronic waste pellets with a particle size of 10-15mm, and then mix the electronic waste pellets with slagging agent and binder according to the mass ratio of 1: 0.4∶0.1 After uniform mixing, use N 2 In the protected indirect heating sintering method, the sintering process is carried out at a temperature of 600°C to obtain sintered agglomerates and generate sintering gas at the same time; among them, the slagging agent is limestone, dolomite, and quartz sand mixed in a mass ratio of 2:1:1. The binder is peat;

[0074] 2) Plasma gasification smelting: Alternately put the agglomerates and coke obtained in step 1) into the plasma gasification smelting furnace at a mass ratio of 1:0.6, so that the two are alternately arranged in layers in the longitudinal direction, and at the same t...

Embodiment 3

[0077] Embodiment 3: A method for comprehensive recycling of electronic waste, comprising the following steps:

[0078] 1) Pellet sintering: first cut and crush waste mobile phones into electronic waste pellets with a particle size of 0.1-3mm, and then combine the electronic waste pellets with slagging agent and binder at a mass ratio of 1:0.5:0.1 After uniform mixing, use N 2 In the protected indirect heating sintering method, the sintering process is carried out at a temperature of 780°C to obtain sintered blocks and generate sintering gas at the same time; among them, the slagging agent is limestone and quartz sand mixed at a mass ratio of 2:3, and the binder is clay. ;

[0079] 2) Plasma gasification smelting: put the sintered agglomerates and coke obtained in step 1) into the plasma gasification smelting furnace alternately at a mass ratio of 1:1, so that the two are alternately arranged in layers in the longitudinal direction; After the sintering gas is collected and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com