Coaxial extruder and extrusion method thereof

An extruder, coaxial technology, applied in the field of coaxial extruder and its extrusion, can solve the problems such as the inability to greatly increase the power and the number of revolutions, the increase of the torque of the screw, and the difficulty of the output limit, and to save energy. The effect of material cost and floor space, improved torsional and bending strength, and easy to ensure machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

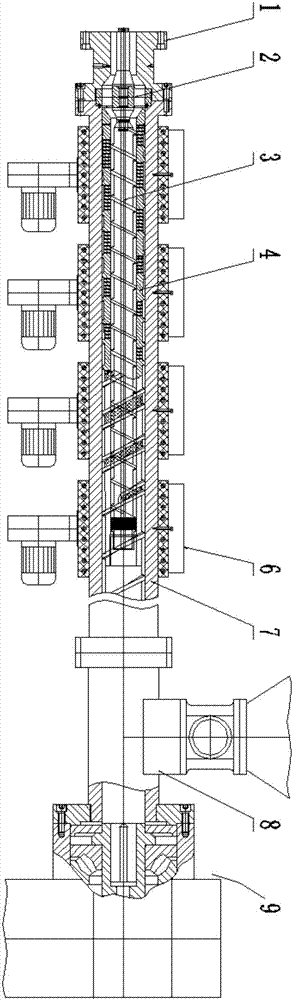

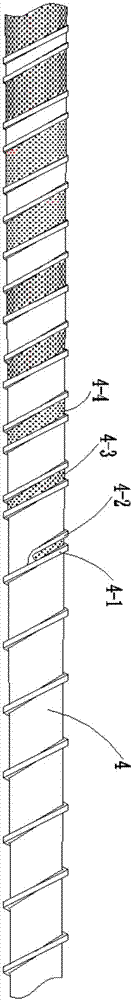

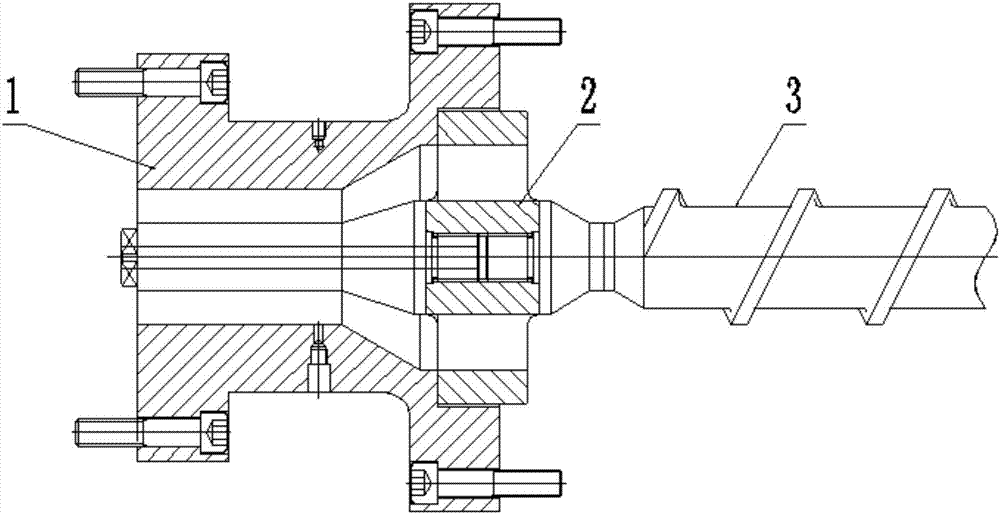

[0019] Embodiment 1: as Figure 1 to Figure 3 As shown, a coaxial extruder of this embodiment includes a mold 1, a rectifying disc 2, an extrusion device, a heater 6, a feeding seat 8 and a power unit 9, and it is characterized in that the extrusion device includes Main screw barrel 7, outer screw 4 and inner screw 3, the two ends of the main screw barrel 7 are respectively connected with the feeding seat 8 and the mold 1, the outer screw 4 is arranged in the main screw barrel 7, and is driven by a power unit 9 It rotates in the main screw barrel 7; the inner screw 3 is arranged in the outer screw 4, and is threadedly connected with the rectifier disc 2 arranged at the joint between the mold 1 and the main screw barrel 7; the inner screw 3 and the outer screw 4 The direction of rotation of the threads is opposite, and an additional thread 4-2 with the same direction of rotation as the main thread 4-1 is added between the main threads 4-1 on the outside of the external screw 4,...

Embodiment 2

[0027] Embodiment 2: An extrusion method of a coaxial extruder, the outer screw 4 rotates, and the raw material in the thread groove of the outer screw 4 is transported to the direction of the mold 1 under the rotation of the outer screw 4, and the raw material is added during the transport process. The thread groove 4-3 gradually melts, and the molten raw material enters the thread groove of the internal screw 3 through the molten material channel 4-4 between the additional thread 4-2 and the main thread 4-1, and the unmelted raw material continues to the mold 1 After melting, it enters the thread groove of the internal screw 3 through the molten material channel 4-4, and the molten raw material in the thread groove of the internal screw 3 rotates along the thread groove and continues to be transported to the direction of the mold 1 until it enters through the rectifying disc 2 Die 1 completes the extrusion process.

[0028] Preferably, the molten raw material enters the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com