Electronic automatic pallet device

A pallet and electronic technology, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of destroying product quality, increasing labor costs, safety accidents, etc., to ensure product quality, improve production efficiency, and save money. The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

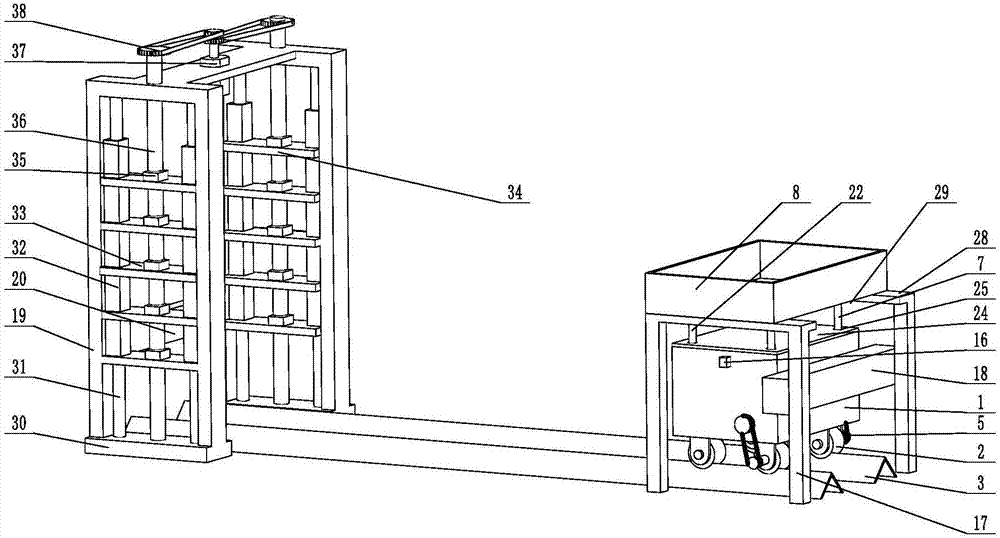

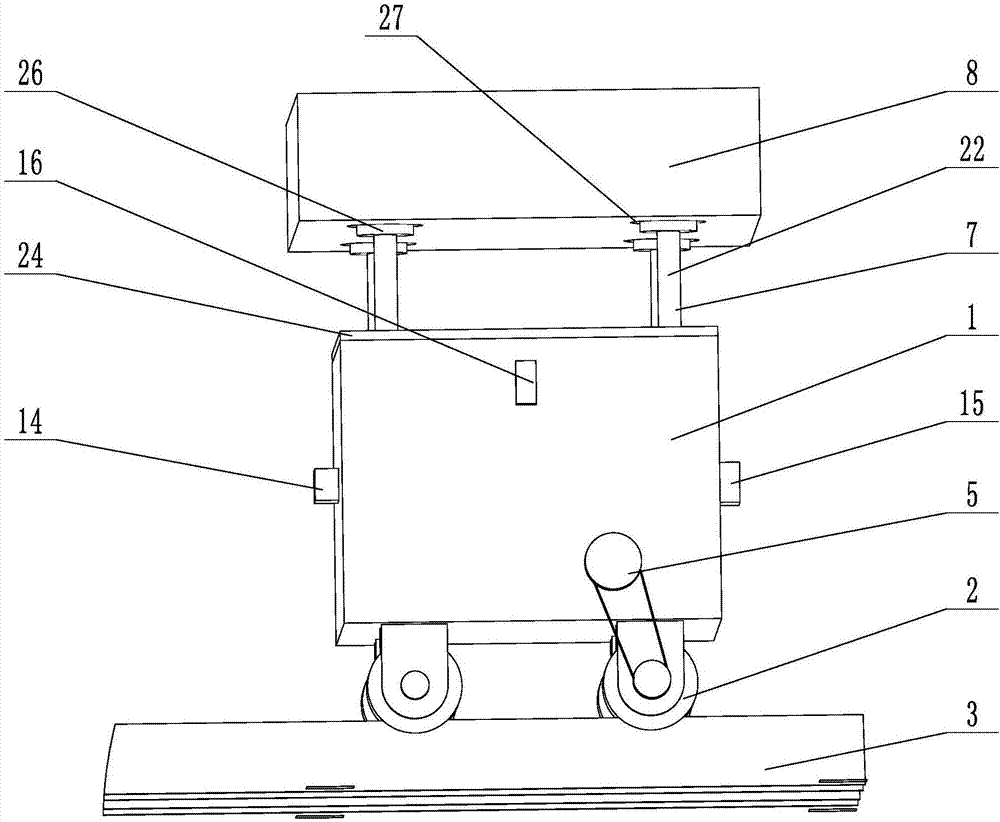

[0033] When the present invention is in use, the initial position of the present invention is at the bottom of the rack 17, and the inner contour of the rack 17 is compatible with the outer contour of the housing 1, and a rack 8 is placed above the rack, and the bottom of the rack 8 is in contact with the lifting device 7. The lifting device 7 is now in a raised state, and supports the storage board 8 . The storage board 8 is used to place the processed semi-finished products. After the semi-finished product is placed on the storage board 8, the operator touches the third travel switch 16, and the third travel switch 16 transmits the signal to the single-chip microcomputer 9, and the single-chip microcomputer 9 processes the signal and controls the first motor 4 through the first motor drive module 10 Running, the first motor 4 drives the wheel set 2 to advance on the track 3 through the first transmission device 5. When the device moves to the key point of the track 3, that i...

Embodiment

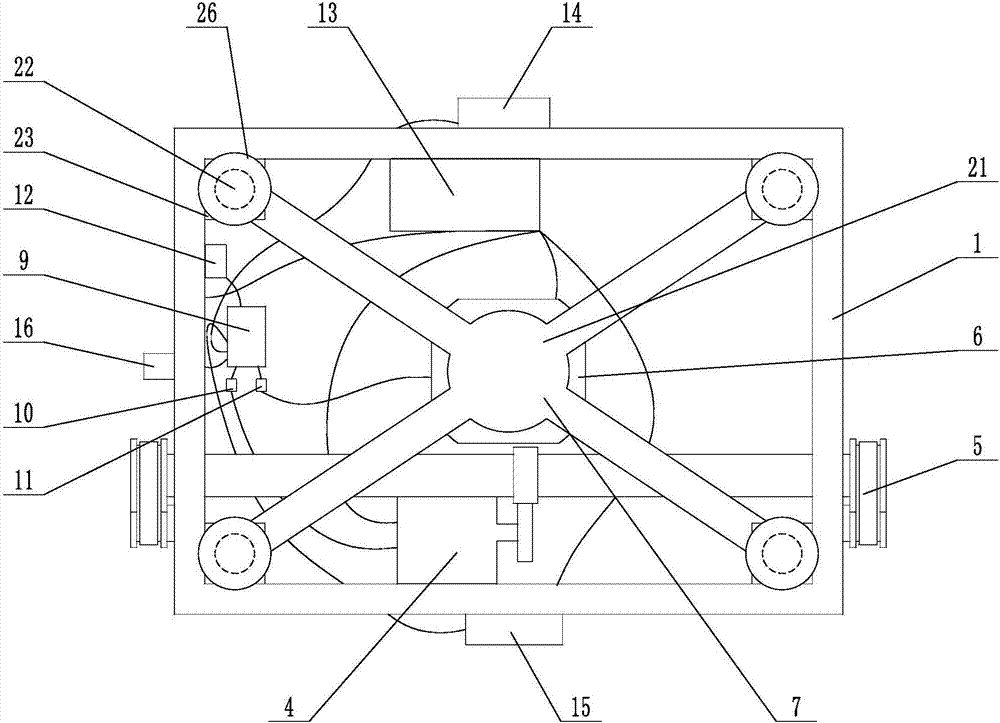

[0035] The electronic automation tray device includes a housing 1, which can be made of hard plastic or metal. In this embodiment, metal plates are welded and formed. In this embodiment, the housing is in the shape of a cuboid. The bottom of the housing 1 is provided with a wheel set 2. In this embodiment, the wheel set includes two pairs of wheels, and the two pairs of wheels are arranged opposite to each other. The middle part of the outer profile of the wheel is provided with an annular groove, the bottom of the wheel set 2 is provided with a track 3, and the track 3 is fixed on the ground, and the height of the track 3 is lower than the ground level. In this embodiment, the track 3 is made of two parallel undercut angle steels, and the track matches with the annular groove so that the wheels can rotate on the track. A first motor 4 is arranged on the bottom surface of the inner contour of the housing 1, and the first motor is fixed to the bottom of the housing by bolts, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com