A method for preparing a self-repairing transducer based on a forest-type graphene interwoven network

An interweaving network and graphene technology, applied in the field of graphene, can solve the problems of inability to balance strain resistance and stability, unstable self-healing performance, and failure to use normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

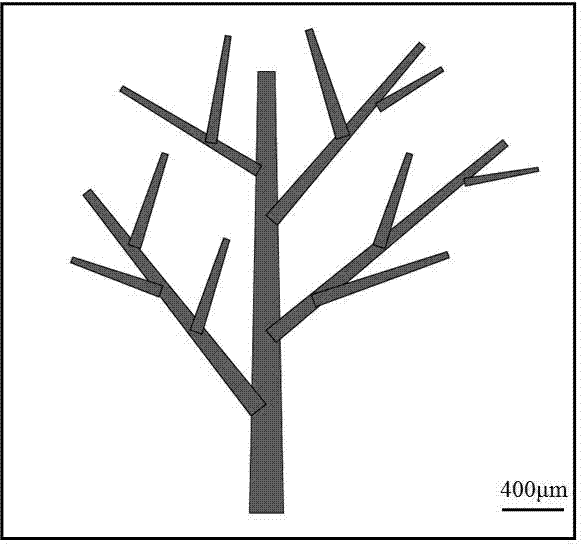

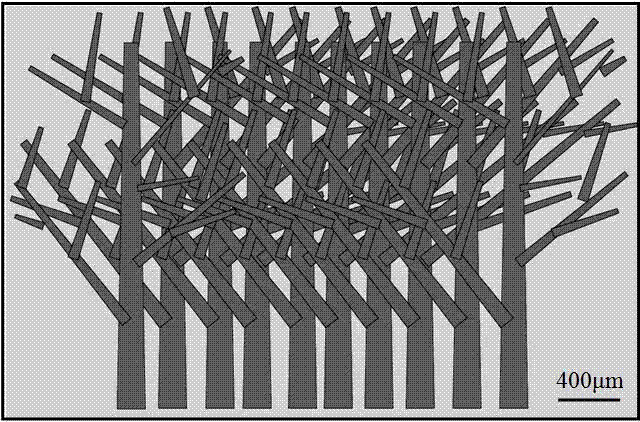

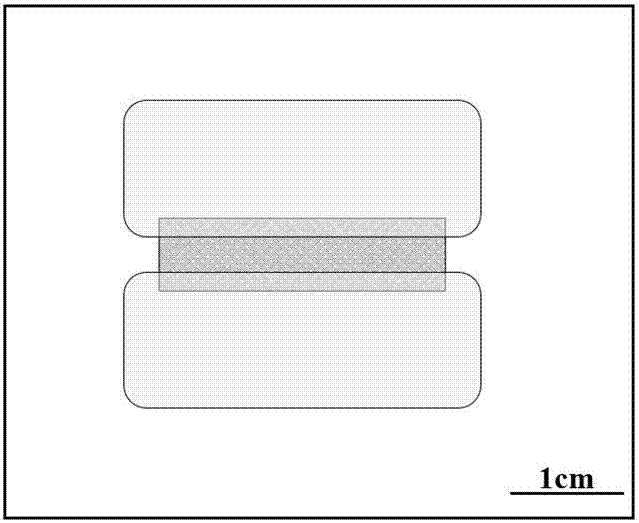

[0040] S1. Cut the forest-like nickel dendrite interwoven network with a dendrite diameter of about 200 μm, a dendrite length of 2000 μm, a thickness of 0.3 mm, and a pore density of 70% to a size of 2*3 cm, such as figure 1 and figure 2 As shown, put it into a mixed solution of equal volume of alcohol and acetone, clean it with ultrasonic waves of 200-400W for 40-80 minutes, rinse it with deionized water repeatedly, and then dry it with argon to obtain a cleaned and dried forest. A nickel dendrite interwoven network template, using the cleaned and dried forest-like nickel dendrite interwoven network as a growth template, using a chemical vapor deposition method, a growth temperature of 1005 ° C, a methane flow of 30 sccm, a hydrogen flow of 10 sccm, a growth time of 25 minutes, and cooling. To room temperature, obtain the forest-like graphene interwoven network grown on the growth template;

[0041] S2. Mix the polydimethylsiloxane and its silane coupling agent uniformly in...

Embodiment 2

[0046] S1. Cut the forest-like nickel dendrite interwoven network with a dendrite diameter of about 10 μm, a dendrite length of 2200 μm, a thickness of 0.5 mm, and a pore density of 90% to a size of 2*3 cm, and put it into an equal volume of alcohol and acetone. In the mixed solution, ultrasonically cleaned at 200-400W for 40-80 minutes, then rinsed repeatedly with deionized water, and then dried with argon to obtain a cleaned and dried forest-like nickel dendrite interwoven network template. The forest-like nickel dendrite interwoven network that was cleaned and dried was used as a growth template, and a chemical vapor deposition method was used, the growth temperature was 1000 ° C, the methane flow rate was 35 sccm, the hydrogen flow rate was 15 sccm, and the growth time was 20 minutes. The forest-like graphene interwoven network on ;

[0047] S2. Mix the polydimethylsiloxane and its silane coupling agent uniformly in a mass ratio of 10:1, naturally level for 10 minutes, and...

Embodiment 3

[0052] S1. Cut the forest-like nickel dendrite interwoven network with a dendrite diameter of about 100 μm, a dendrite length of 2000 μm, a thickness of 0.8 mm, and a pore density of 80% to a size of 2*3 cm, and put in an equal volume of alcohol and acetone. In the mixed solution, ultrasonically cleaned at 200-400W for 40-80 minutes, then rinsed repeatedly with deionized water, and then dried with argon to obtain a cleaned and dried forest-like nickel dendrite interwoven network template. The forest-like nickel dendrite interwoven network that was cleaned and dried was used as a growth template, and a chemical vapor deposition method was used, the growth temperature was 1010 ° C, the methane flow rate was 40 sccm, the hydrogen flow rate was 20 sccm, and the growth time was 20 minutes, and cooled to room temperature to obtain the growth template. The forest-like graphene interwoven network on ;

[0053] S2. Mix the polydimethylsiloxane and its silane coupling agent uniformly in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com