Middle-heavy refractory castable in working linings of industrial furnaces and preparation method of refractory castable

A technology for refractory castables and working linings, applied in the field of refractory castables, can solve problems such as large heat loss, and achieve the effects of reducing porosity, improving volume stability, and reducing the amount of water added during construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

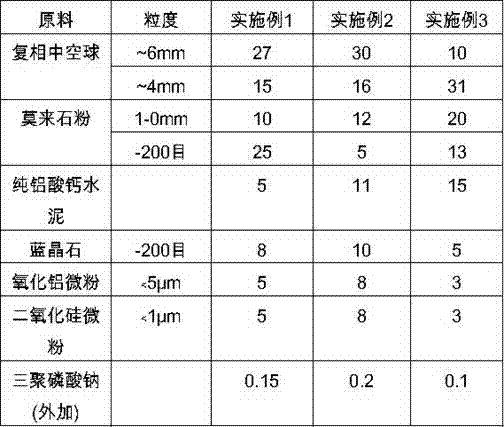

[0034] Preferred embodiments of the present invention will be described in detail below.

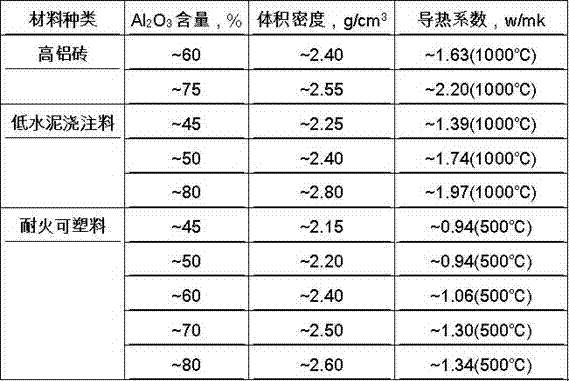

[0035] In order to achieve the purpose of the present invention, in one of the embodiments of the present invention, a medium-heavy refractory castable for the working lining of an industrial kiln is provided, which includes the following components according to mass percentage:

[0036] Complex phase hollow ball: ~6mm: 10-30%

[0037] ~4mm: 15-35%

[0038] Mullite: 1-0mm: 10-25%

[0039] Kyanite: -180 mesh: 5-25%

[0040] Mullite powder: -200 mesh: 5-15%

[0041] Pure calcium aluminate cement: 5-10%

[0042] Alumina micropowder: ﹤5μm 3-8%

[0043] Silica powder: ﹤1μm 3-8%

[0044] Additional water reducer: +0.1-0.2%.

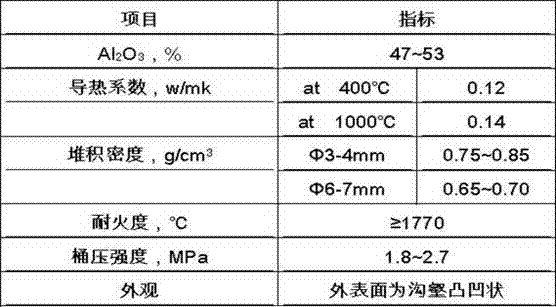

[0045] Among them, Al in the complex phase hollow sphere 2 o 3 The content of Al is 47-53%; Al in mullite 2 o 3 The content of Kyanite is ≥60%; Al in kyanite 2 o 3 The content of Al is ≥45%; Al in pure calcium aluminate cement 2 o 3 The content of Al is ≥68...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com