an anti-slip fluid

A technology of anti-slip liquid and organic acid, applied in the field of anti-slip liquid, can solve the problems of unsuitable anti-skid treatment of household floors, aging of floor paint, and restricted wide use, etc. The effect of slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

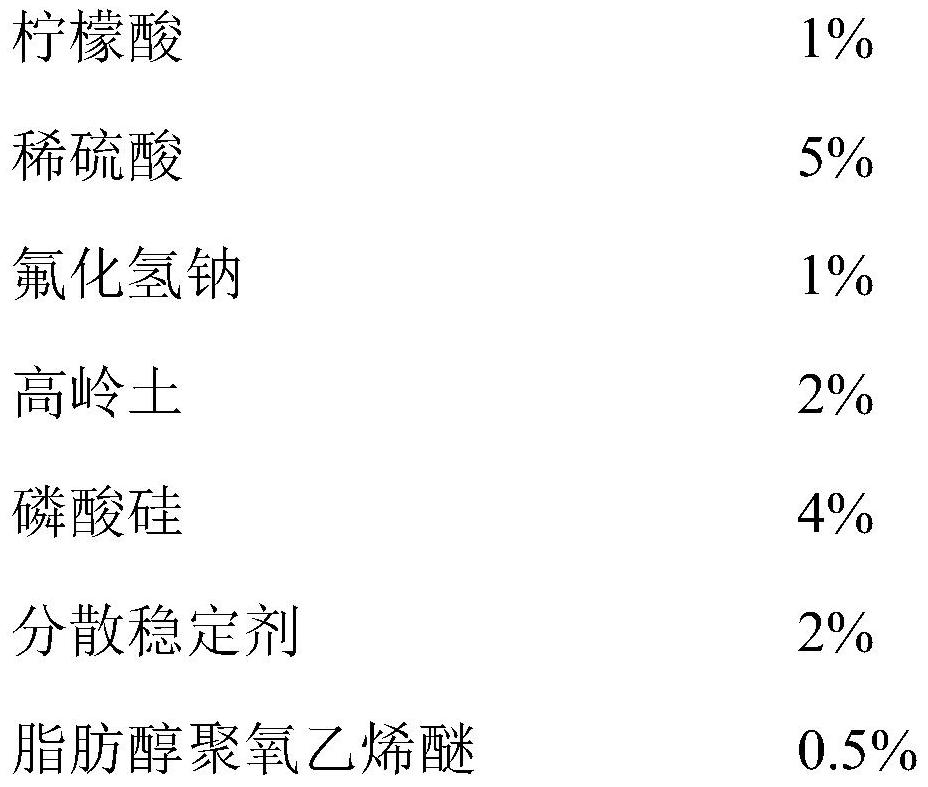

[0058] This kind of anti-slip liquid, with the total weight of anti-slip liquid as 100%, comprises the following raw materials in weight percentage:

[0059]

[0060]

[0061] Wherein, the dispersion stabilizer is a two-component mixture composed of ethylene glycol monobutyl ether and isopropanol, and the weight ratio of ethylene glycol monobutyl ether and isopropanol is 1.5:1.

Embodiment 2

[0063] A kind of anti-slip liquid, with the total weight of anti-slip liquid as 100%, comprises the raw material of following percentage by weight:

[0064]

[0065] Wherein, the dispersion stabilizer is a two-component mixture composed of ethylene glycol monobutyl ether and isopropanol, and the weight ratio of ethylene glycol monobutyl ether and isopropanol is 2:1.

Embodiment 3

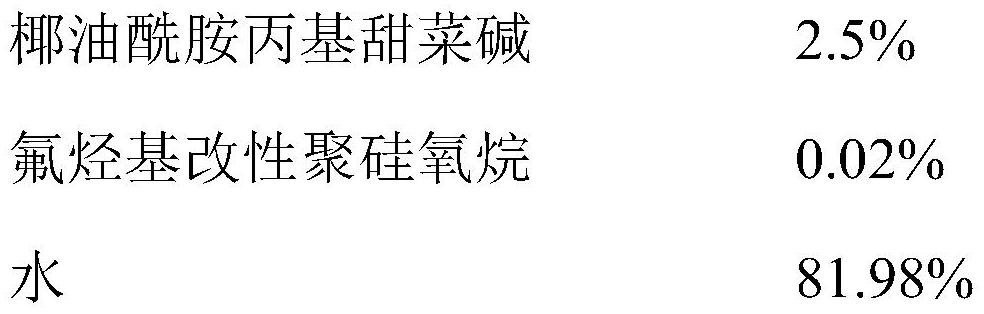

[0067] A kind of anti-slip liquid, with the total weight of anti-slip liquid as 100%, comprises the raw material of following percentage by weight:

[0068]

[0069]

[0070] Wherein, the dispersion stabilizer is a two-component mixture composed of ethylene glycol monobutyl ether and isopropanol, and the weight ratio of ethylene glycol monobutyl ether and isopropanol is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com