Straw modified elastomer pen rod, and preparation method thereof

An elastomer and straw technology, applied in the direction of pen, printing, writing utensils, etc., can solve the problems of low surface hardness and thermal deformation temperature of ultra-high molecular weight polyethylene, poor bending strength and creep performance, etc., to improve wear resistance and Feel, improve antibacterial properties, feel good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

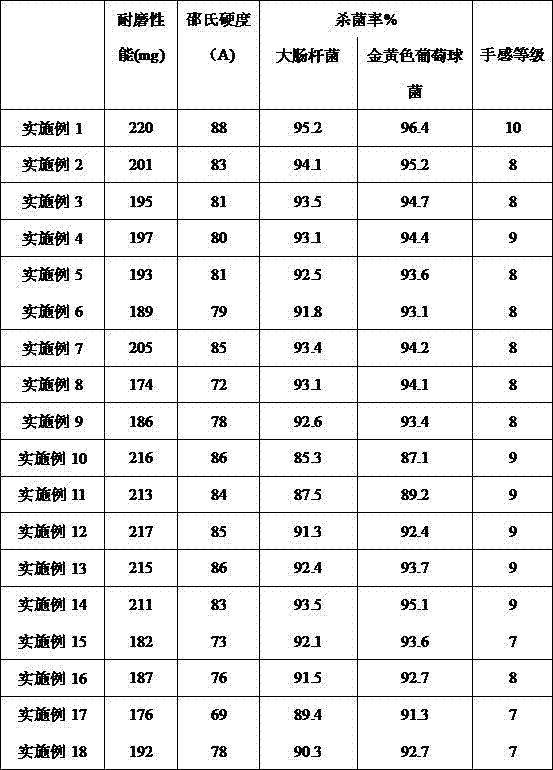

Examples

Embodiment 1

[0030] (1) putting 10 parts by weight of wheat straw and 4 parts by weight of soybean straw into 10% sodium bicarbonate solution and soaking for 6 hours, washing them with clean water, and then performing dispersing and refining treatment to obtain straw pulp fibers;

[0031] (2) 25 parts by weight of styrene-butadiene-styrene block copolymer, 75 parts by weight of styrene-isoprene-styrene block copolymer, 46 parts by weight of ultra-high molecular weight polyethylene (molecular weight 200000) , 0.4 parts by weight of azodicarbonamide, 0.3 parts by weight of sodium bicarbonate, 0.7 parts by weight of dicumyl peroxide, 2 parts by weight of lanthanum oxide, and 0.8 parts by weight of zinc oxide. Mix evenly in the machine, add it to the hopper of the twin-screw extruder, and through melting reaction, add 10 parts by weight of carbon black, 5 parts by weight of wollastonite powder and 2 parts by weight of talc powder in the fourth zone by side feeding , and then extruded and granu...

Embodiment 2

[0034] (1 Put 10 parts by weight of wheat straw and 4 parts by weight of soybean straw into 10% sodium bicarbonate solution and soak for 6 hours, wash them with clean water, and then perform disentanglement and grinding to obtain straw pulp fibers;

[0035] (2) 20 parts by weight of styrene-butadiene-styrene block copolymer, 80 parts by weight of styrene-isoprene-styrene block copolymer, 46 parts by weight of ultra-high molecular weight polyethylene (molecular weight 200000) , 0.4 parts by weight of azodicarbonamide, 0.3 parts by weight of sodium bicarbonate, 0.7 parts by weight of dicumyl peroxide, 2 parts by weight of lanthanum oxide, and 0.8 parts by weight of zinc oxide. Mix evenly in the machine, add it to the hopper of the twin-screw extruder, and through melting reaction, add 10 parts by weight of carbon black, 5 parts by weight of wollastonite powder and 2 parts by weight of talc powder in the fourth zone by side feeding , and then extruded and granulated to obtain the...

Embodiment 3

[0038] (1 Put 10 parts by weight of wheat straw and 4 parts by weight of soybean straw into 10% sodium bicarbonate solution and soak for 6 hours, wash them with clean water, and then perform disentanglement and grinding to obtain straw pulp fibers;

[0039] (2) 33 parts by weight of styrene-butadiene-styrene block copolymer, 67 parts by weight of styrene-isoprene-styrene block copolymer, 46 parts by weight of ultra-high molecular weight polyethylene (molecular weight 200000) , 0.4 parts by weight of azodicarbonamide, 0.3 parts by weight of sodium bicarbonate, 0.7 parts by weight of dicumyl peroxide, 2 parts by weight of lanthanum oxide, and 0.8 parts by weight of zinc oxide. Mix evenly in the machine, add it to the hopper of the twin-screw extruder, and through melting reaction, add 10 parts by weight of carbon black, 5 parts by weight of wollastonite powder and 2 parts by weight of talc powder in the fourth zone by side feeding , and then extruded and granulated to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com