Red bismuth phosphate fluorescent material, preparation method and application thereof

A technology of bismuth phosphate and fluorescent material, applied in the field of red bismuth phosphate fluorescent material and its preparation, can solve the problems of environmental pollution, poor chemical stability, loss and the like, and achieve the effect of high luminous brightness and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

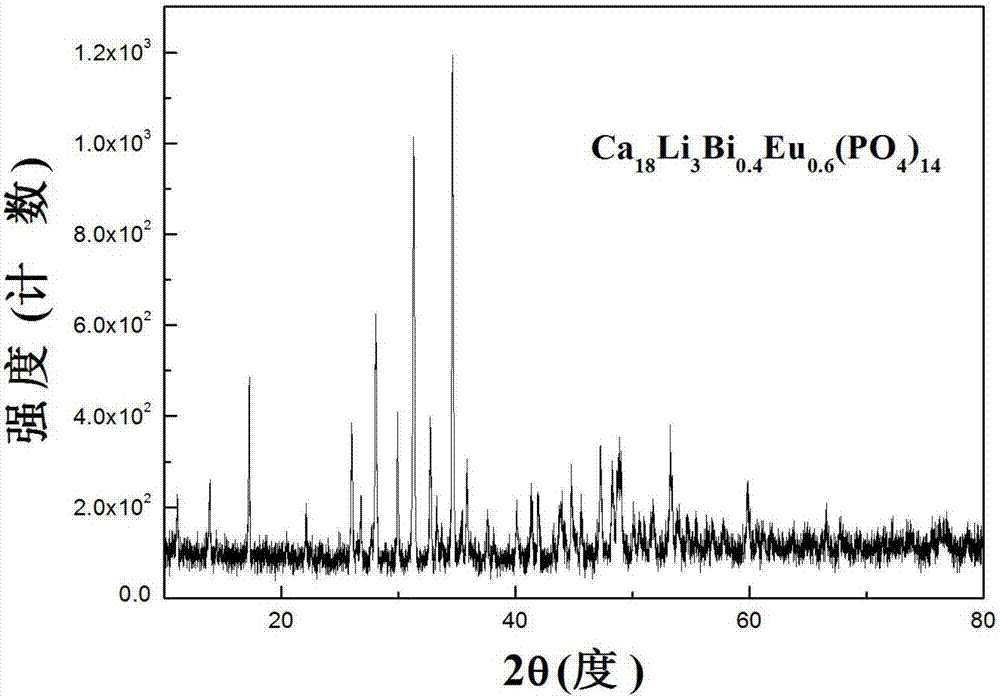

[0046] (1) According to the chemical formula Ca 18 Li 3 Bi 0.4 Eu 0.6 (PO 4 ) 14 Composition Weigh 0.8019gCaCO 3 , 0.0493g Li 2 CO 3 , 0.0415gBi 2 o 3 ,0.1191g Eu(NO 3 ) 3 ·6H 2 O and 0.8229g (NH 4 ) 2 HPO 4 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder.

Embodiment 2

[0049] (1) According to the chemical formula Ca 18 Li 3 Bi 0.2 Eu 0.8 (PO 4 ) 14 Composition Weigh 1.9017gCa(NO 3 ) 2 4H 2 O, 0.0321gLiOH, 0.0208gBi 2 o 3 ,0.1311gEuCl 3 ·6H 2 O and 0.4445gP 2 o 5 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder.

Embodiment 3

[0052] (1) According to the chemical formula Ca 18 Li 3 Bi 0.005 Eu 0.995 (PO 4 ) 14 Composition Weigh 1.2801gCa(CH 3 COO) 2 , 0.0323gLiOH, 0.0005gBi 2 o 3 ,0.1647gEuCl 3 ·6H 2 O and 0.4468gP 2 o 5 , and grind for 30 minutes to mix the raw materials evenly to obtain a mixed powder.

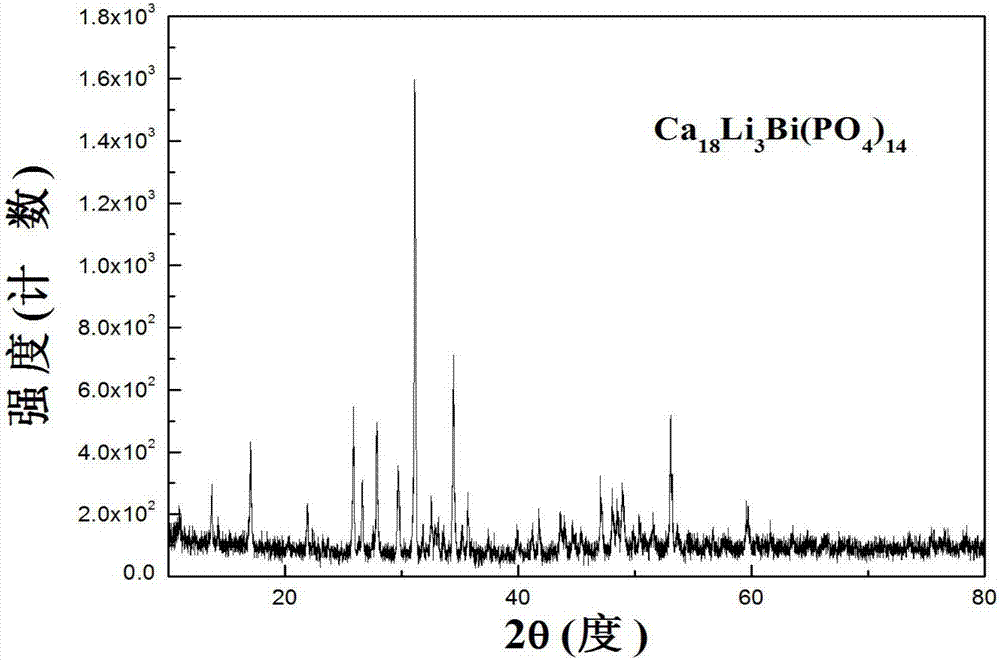

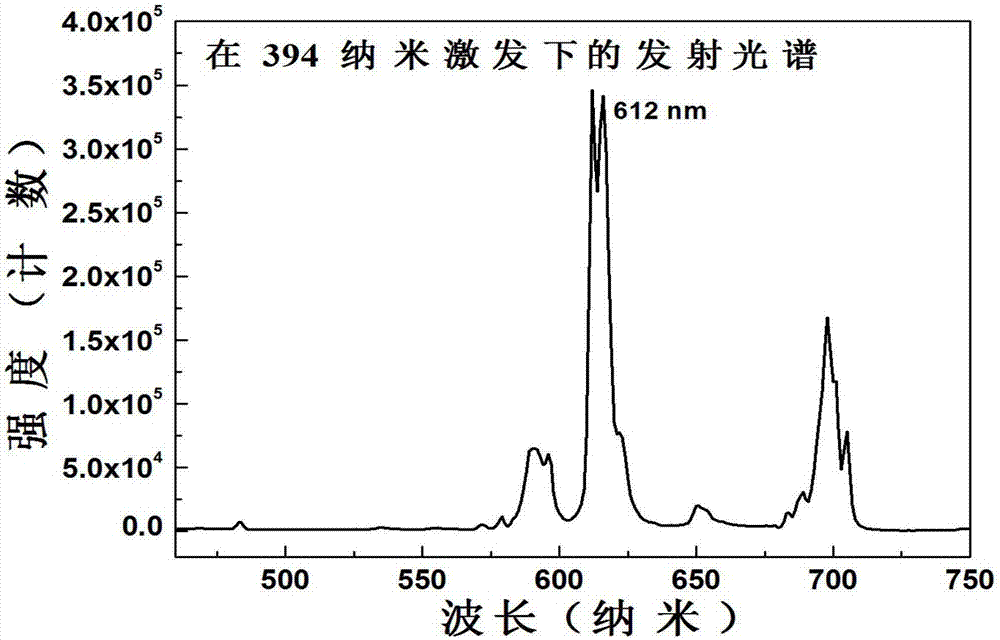

[0053] (2) Put the mixed powder into a corundum crucible, put it into a tubular atmosphere furnace, raise the temperature to 800°C at a rate of 5°C / min, keep it warm for 2 hours, and then increase the temperature to 1180°C at a rate of 5°C / min ℃, keep it warm for 8 hours, then lower it to 500 ℃ at a rate of 5 ℃ / min, then cool it down to room temperature naturally, take out the obtained powder and grind it into powder to obtain the required phosphor material. Figure 10 The XRD spectrum of the sample obtained in Example 4 is shown, and its basic structure is composed of β-Ca 3 (PO 4 ) 2 Structure and composition. Figure 11 with Figure 12 The excitation and emission spectra of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com