A method for enzyme-catalyzed organic chemical reactions in redox stimulus-responsive pickering emulsions

A stimuli-responsive, emulsion technology, applied in the field of physical chemistry, can solve the problems of low recycling rate, difficult enzyme recovery, low reaction efficiency, etc., and achieve the effect of enhancing contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

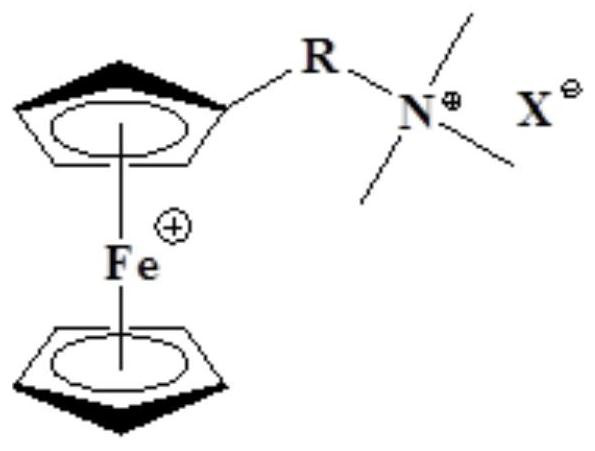

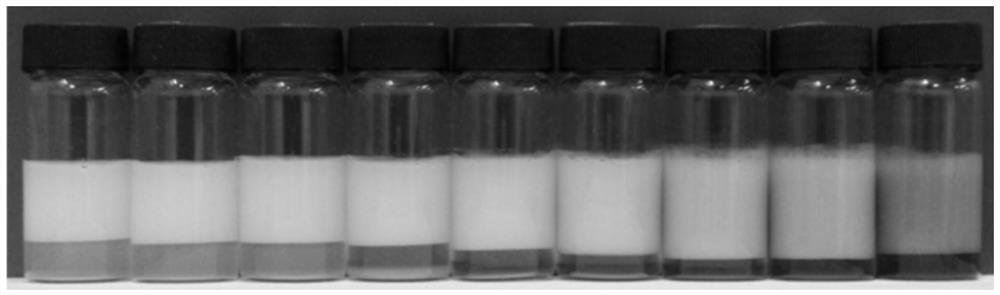

[0022] Example 1: Nano-SiO 2 Pickering emulsion prepared jointly by granules, FTMA and lipase. In a series of cylindrical flasks with a volume of 25mL, accurately weigh nano-SiO with a mass fraction of 0.5% (relative to the aqueous phase) 2 , add 7 mL of FTMA solution of different concentrations. Use an ultrasonic disperser to disperse the particles (90W, 15s). After the nanoparticles are uniformly dispersed, add a certain amount of lipase solution (the final concentration of lipase in the water phase is 1mg·mL -1 ) and 7mL of isooctane, emulsified with a homogenizer (IKA ULTRA-TURRAX T18basic) for 2min at a homogenization rate of 11000rpm to obtain an O / W Pickering emulsion, and the appearance of the emulsion was taken after standing, as shown in figure 2 and image 3 shown.

Embodiment 2

[0023] Example 2: Pickering emulsion prepared jointly by nano calcium carbonate particles, FTMA and reductase. Take 7mL of a series of surfactant aqueous solutions and put them into 25mL columnar vials, add 0.03g of commercial nano-calcium carbonate particles (primary particle diameter is about 10nm, BET specific surface area is 250m 2 / g), use an ultrasonic disperser to disperse the particles (50W, 1min), add 7mL of n-heptane and a certain amount of reductase solution (the final concentration of reductase in the aqueous phase is 1mg·mL -1 ), and emulsified for 2 minutes with a high-shear emulsifier to obtain a stable O / W Pickering emulsion.

Embodiment 3

[0024] Example 3: Pickering emulsion jointly prepared by nano-titanium dioxide particles, FTMA and transferase. Take 7mL of surfactant aqueous solutions with a series of concentrations and put them into 25mL columnar vials, add 0.03g of commercial nano-titanium dioxide particles (primary particle diameter is about 20nm, BET specific surface area is 300m 2 / g), use an ultrasonic disperser to disperse the particles (50W, 1min), add 7mL of isooctane and a certain amount of transferase solution (the final concentration of reductase in the aqueous phase is 1.5mg·mL -1 ), and emulsified for 2 minutes with a high-shear emulsifier to obtain a stable O / W Pickering emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com