FeSe2 nanocomposite material and synthetic method and application thereof

A nanocomposite material and iron diselenide technology are applied in the field of iron diselenide nanocomposite materials and their synthesis, and can solve the problems of poor hydrogen production performance, poor distribution uniformity of iron diselenide nanocomposite materials, and the like, Achieve the effects of good electrochemical hydrogen production performance, improved electron transport efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

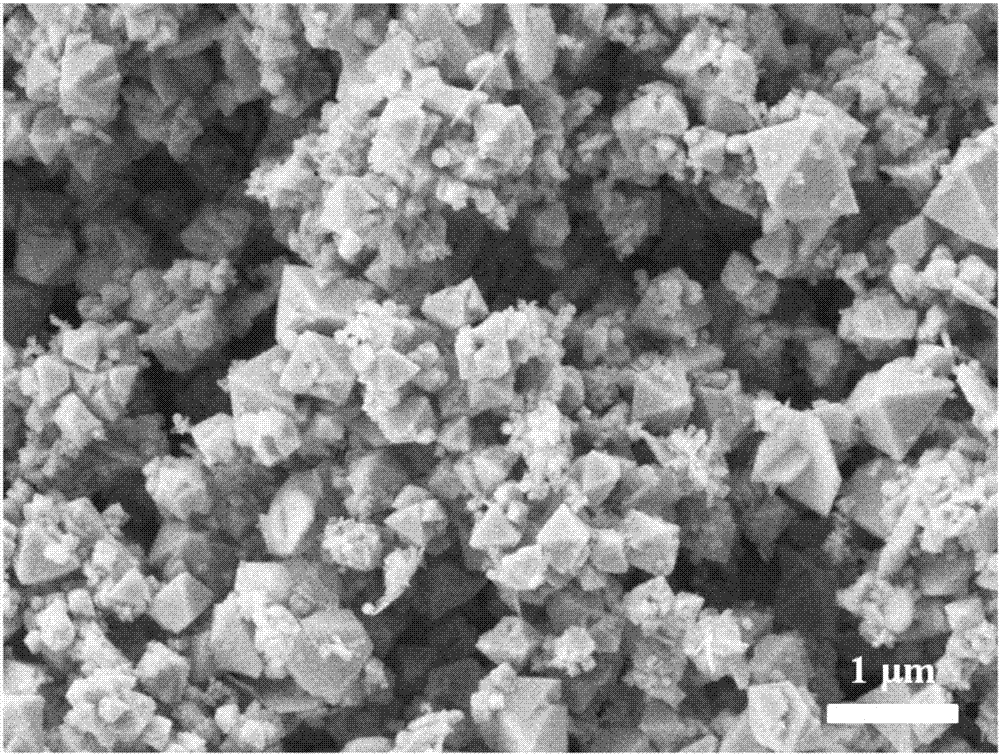

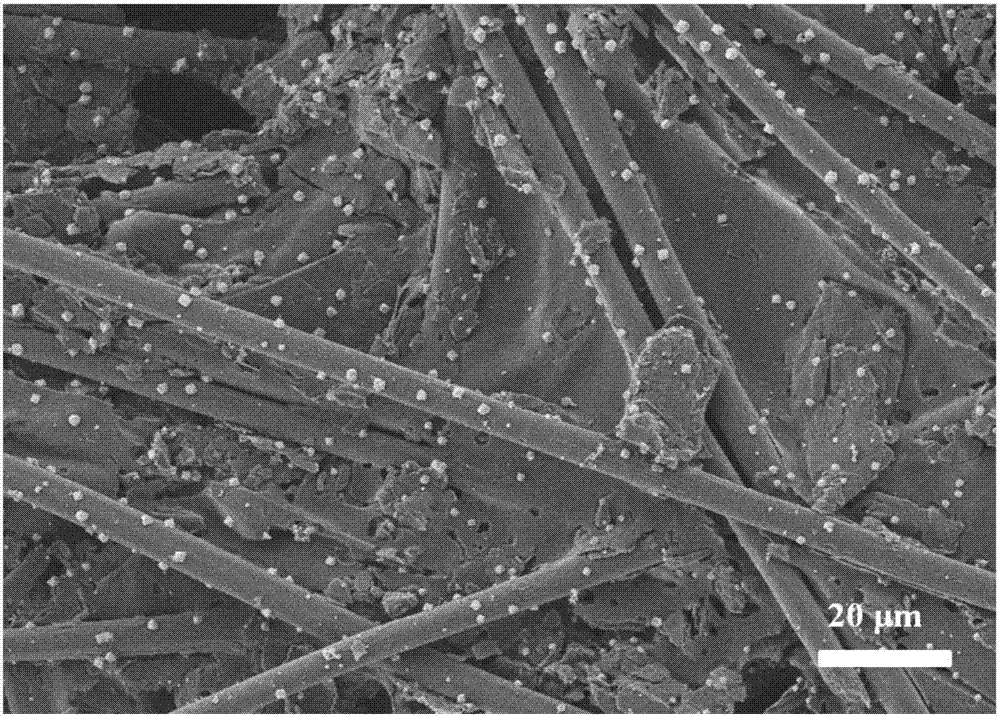

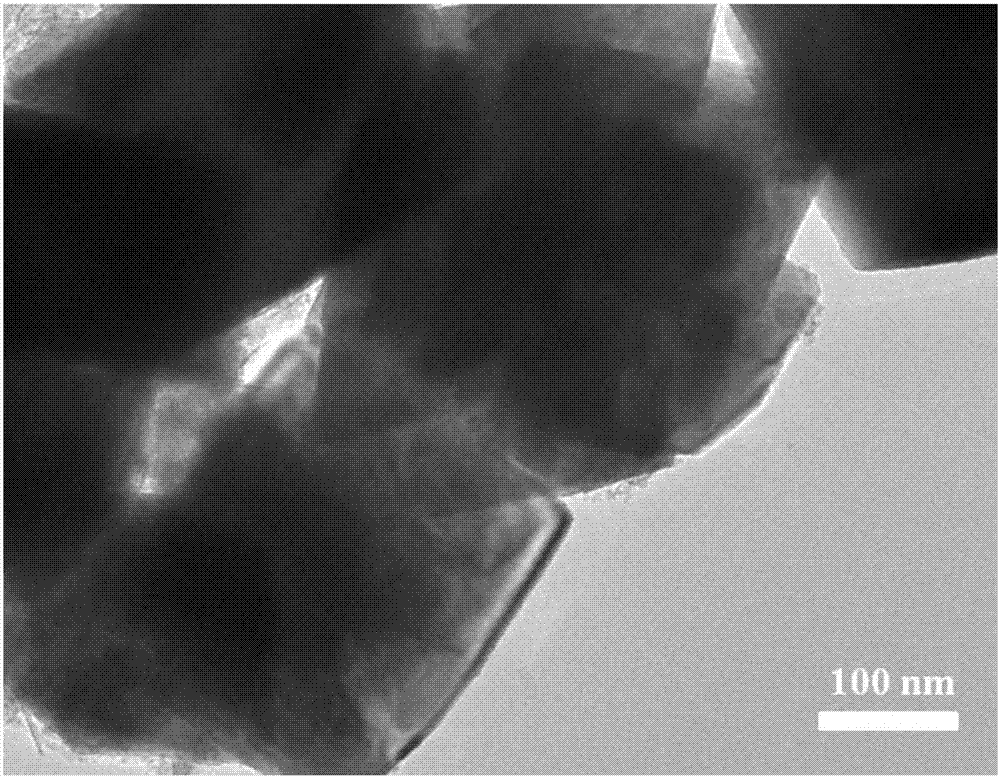

[0057] Embodiment 1, the preparation of iron diselenide nanocomposite material

[0058] Cut 2×3cm 2 Long strips of carbon fiber paper were sonicated in 6M HCl, deionized water, and absolute ethanol for 10 minutes, and then dried in a vacuum oven at 60°C for 1 hour. After treatment, they were placed in an autoclave liner. Measure 15ml of dimethylamide (DMF) and 15ml of absolute ethanol in a clean beaker, and stir them with a magnetic force to mix them evenly. Then add 0.5 mmol of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and the selenium powder of 1mmol, stir 10min. Finally, 1 mmol of urea was added and stirred for five minutes. After the stirring was completed, the solution was transferred into a reaction kettle and reacted at 180° C. for 12 hours. After the reaction is complete, take out the reaction kettle, cool it to room temperature, rinse the carbon fiber paper with FeSe2 with water and ethanol several times in sequence, and wash the precipitated product in the ke...

Embodiment 2

[0069] Embodiment 2, the preparation of iron diselenide nanocomposite material

[0070] Cut 2×3cm 2 Long strips of carbon fiber paper were sonicated in 6M HCl, deionized water, and absolute ethanol for 10 minutes, and then dried in a vacuum oven at 60°C for 1 hour. After treatment, they were placed in an autoclave liner. Measure 20ml of dimethylamide (DMF) and 10ml of absolute ethanol in a clean beaker, and stir them with a magnetic force to mix them evenly. Then add 0.5 mmol of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and 1mmol of selenium powder, stirred for 10min. Finally, 1 mmol of urea was added and stirred for five minutes. After the stirring was completed, the solution was transferred into a reaction kettle and reacted at 180° C. for 12 hours. After the reaction is completed, the reactor is taken out, cooled to room temperature, and FeSe 2 The carbon fiber paper was rinsed several times with water and ethanol in turn, and the precipitated product in the kettle...

Embodiment 3

[0071] Embodiment 3, the preparation of iron diselenide nanocomposite material

[0072] Cut 2×3cm 2 Long strips of carbon fiber paper were sonicated in 6M HCl, deionized water, and absolute ethanol for 10 minutes, and then dried in a vacuum oven at 60°C for 1 hour. After treatment, they were placed in an autoclave liner. Measure 15ml of dimethylamide (DMF) and 15ml of absolute ethanol in a clean beaker, and stir them with a magnetic force to mix them evenly. Then add 0.5 mmol of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) and the selenium powder of 1mmol, stir 10min. Finally, 2 mmol of urea was added and stirred for five minutes. After the stirring was completed, the solution was transferred into a reaction kettle and reacted at 180° C. for 12 hours. After the reaction is completed, the reactor is taken out, cooled to room temperature, and FeSe 2 The carbon fiber paper was rinsed several times with water and ethanol in turn, and the precipitated product in the kettle wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com