Method for coalbed gas draining and colleting of water and gas producing of oil pipe

A technology for coalbed methane and coalbed methane wells, which is applied in the fields of fluid production, earthwork drilling, and wellbore/well valve devices. , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

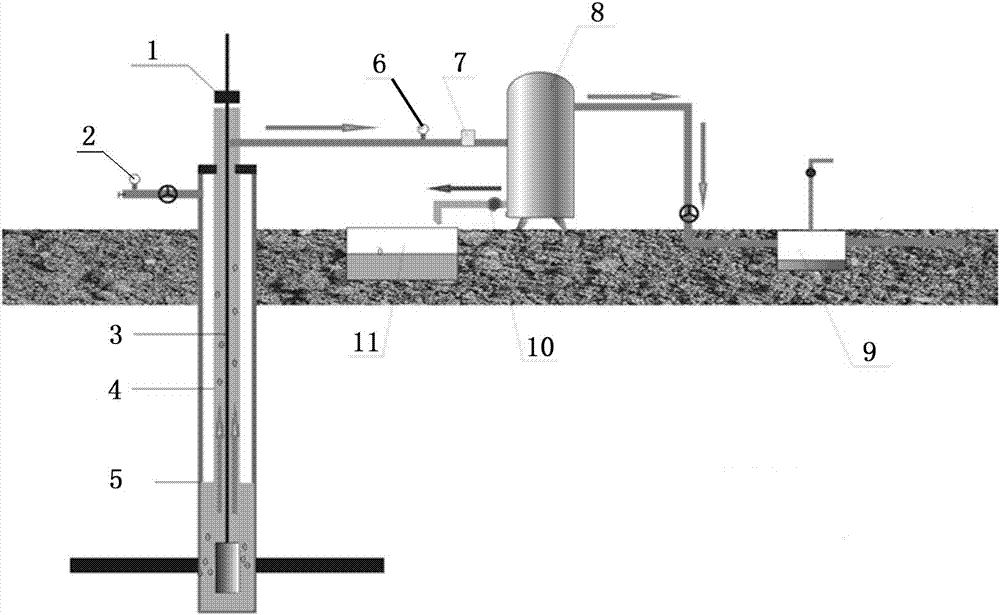

[0019] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

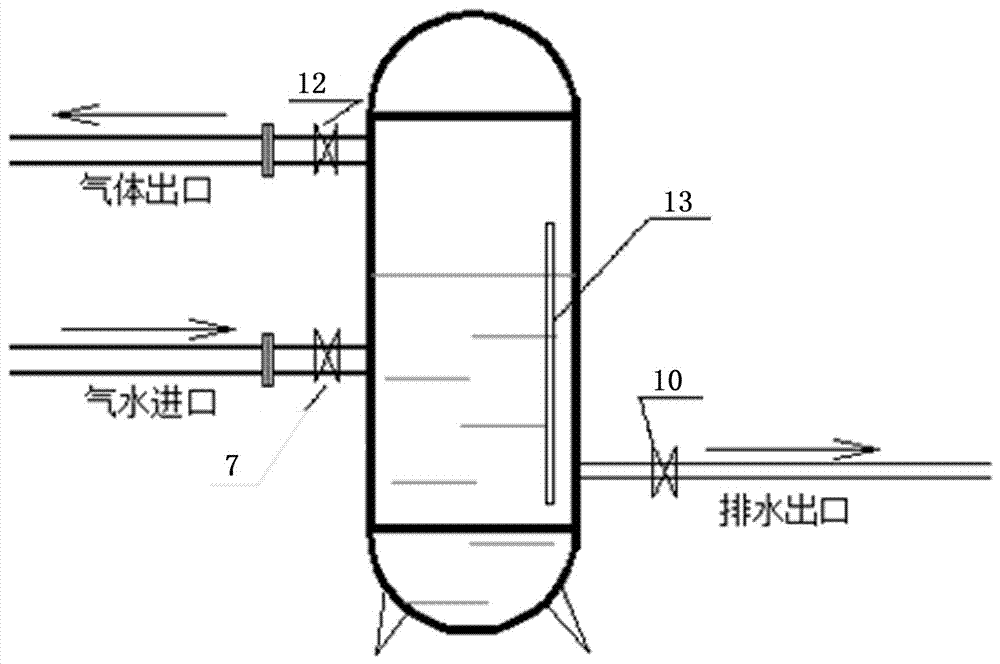

[0020] Press as figure 1 Install a high-efficiency gas-water separator as shown, connect the water and gas main pipe, gas outlet pipeline, and water outlet pipeline as required, and set the pressure value of the solenoid valve to the expected value.

[0021] After drainage starts, water and gas are discharged from the oil pipe, and enter the gas-water separator through the pressure limiting valve, the gas enters the manifold through the gas outlet pipeline, and the water enters the pool through the drain pipe.

[0022] When the coal powder is high, chemical reagents are added to the annulus of the oil jacket, and the formed foam gas carries the coal powder and is discharged from the oil pipe.

[0023] The specific construction process requirements are as follows:

[0024] (1) During coalbed methane well drainage, the oil casing annulus is closed, gas and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com