Wireless inclinometer monitoring system based on FLEX bending sensing and 3D printing technologies

A 3D printing and monitoring system technology, applied in signal transmission systems, measuring devices, measuring fluid pressure, etc., can solve problems such as threats to people's normal life, difficult long-term real-time monitoring, and slow response to slope displacement, so as to facilitate collection and processing , light weight and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Example: such as Figure 4 Shown.

[0055] The method for using the wireless inclinometer monitoring system of the present invention includes the following steps:

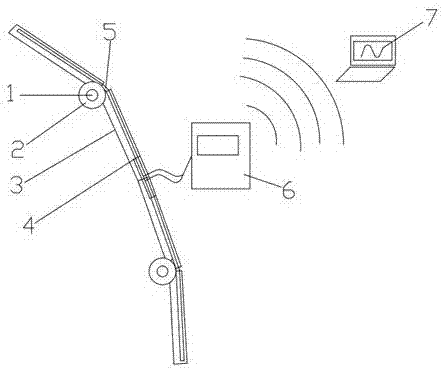

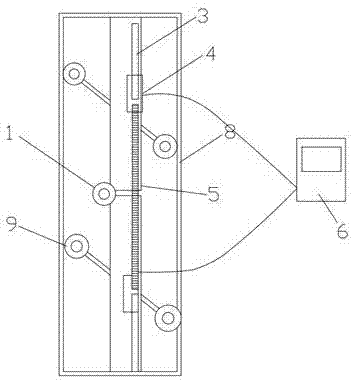

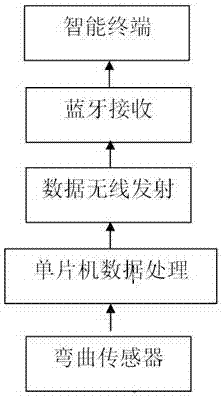

[0056] Step 1: First select the monitoring points on the slope to be monitored, drill each monitoring point to the required monitoring depth, and then drive the inclinometer 8 into the monitoring hole, and use cement mortar to seal and fix the hole. Inclined pipe 8; after the cement is completely hardened, divide the two according to the depth of the inclinometer pipe 8 and the preset monitoring point spacing to obtain the required design length of the package shell 3. It will be designed according to the required length and the size of the FLEX bending sensor A fixed number of 3D printed parts including a hinge bolt 1, a rotating link hinge 2 and a slotted package housing 3 connected to the sensor. The 3D printing assembly is completed, and the FLEX bending sensor is inserted one by one to complete the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com