Waste gas collecting device

A collection device and exhaust gas technology, applied in the direction of measuring device, sampling device, sampling, etc., can solve the problems of uneven sampling, high replacement frequency, low sensitivity, etc., and achieve the effect of being suitable for popularization, accurate detection results, economical and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

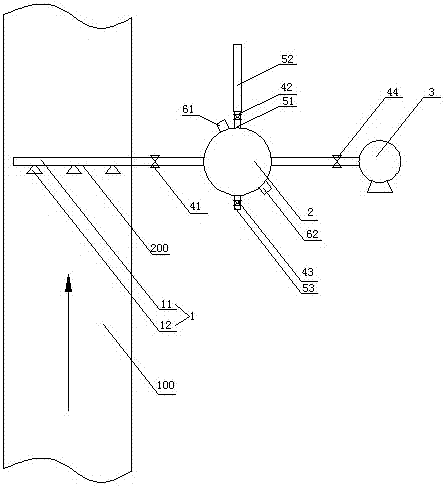

[0028] like figure 1 As shown, an exhaust gas collection device 100 is arranged on an exhaust gas discharge pipe 200 . Arrows in the figure indicate the flow direction of exhaust gas. The exhaust gas collection device includes a sampling pipe 1 , a sampler 2 connected to the sampling pipe, and an air pump 3 connected to the sampler.

[0029] The sampling pipe includes a main pipe 11, and several branch pipes 12 are arranged on one side of the main pipe. type, the activated carbon adsorption layer is filled in the sample loader; the upper side of the sample loader is provided with a liquid inlet 51, which is connected to a liquid inlet pipe 52, and a second valve 42 is arranged between the liquid inlet and the liquid inlet pipe. The lower side of the device is provided with a drain port 53, and the drain port is provided with a third valve 43.

[0030] As an improvement of the present invention, an activated carbon inlet 61 is provided on the upper side of the sample loader,...

Embodiment 2

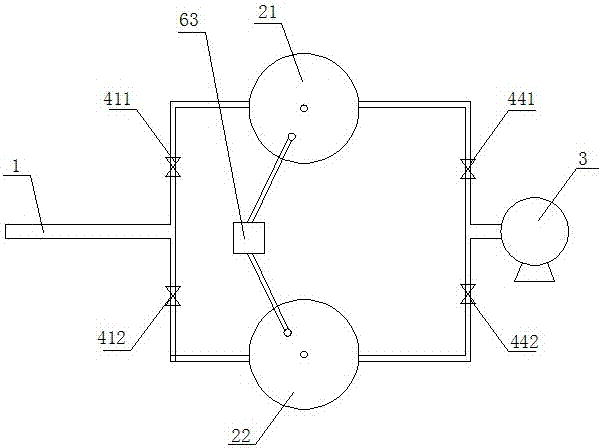

[0037] like figure 2 As shown, an exhaust gas collection device 100, the sampling tube of the exhaust gas collection device is connected to two sample loaders in parallel, the sample loader includes a sample loader A21 and a sample loader B22, and a second A valve A411, a fourth valve A441 is set between the sample loader A and the air pump, a first valve B412 is set between the sample loader B and the sampling tube, and a fourth valve B442 is set between the sample loader B and the air pump. All the other structures are consistent with Example 1.

Embodiment 3

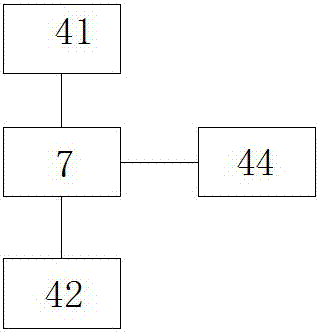

[0039] like image 3 As shown, the exhaust gas collection devices shown in Embodiment 1 and Embodiment 2 are equipped with a controller 7, the controller is electrically connected to the first valve, the second valve, and the fourth valve, and the controller can control the opening and closing of each valve. , can set the opening and closing time of each valve, opening and closing sequence, to achieve accurate operation and reduce errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com