NiS@C nanocomposite material for negative electrode of battery and preparation method of NiS@C nanocomposite material

A nano-composite material and battery anode technology, applied in the field of electrochemistry, can solve the problems of only theoretical capacity, restricting power batteries, lithium dendrite safety problems, etc., and achieve the effects of large specific surface area, improved performance, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

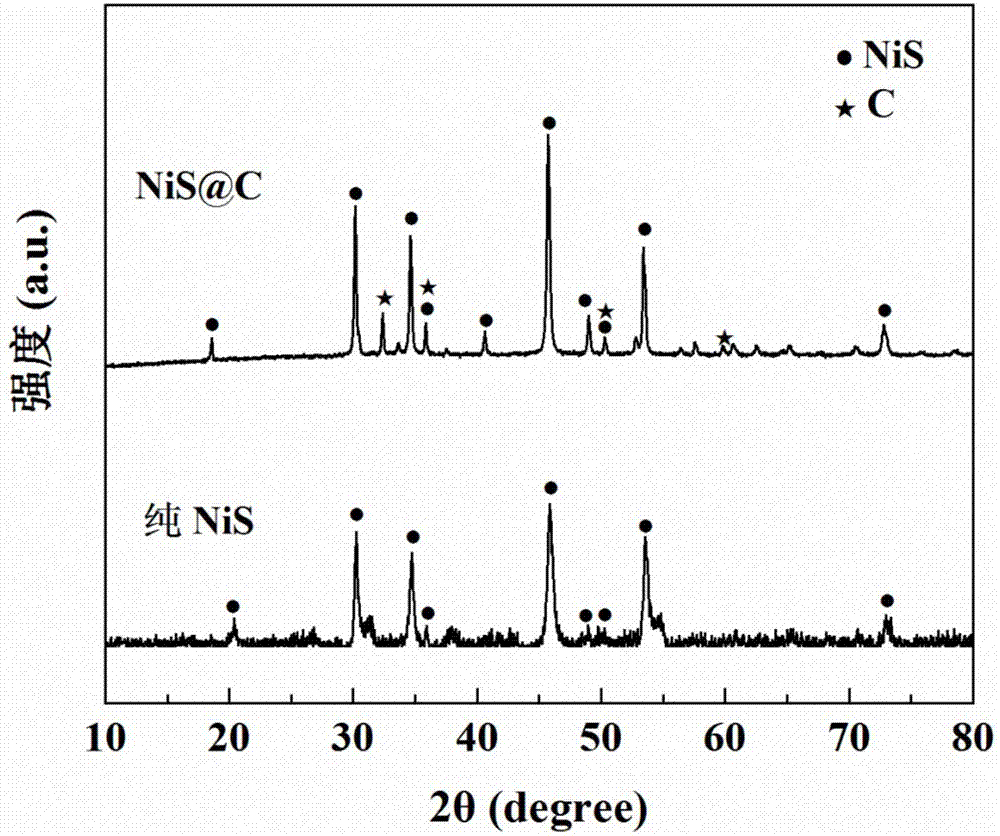

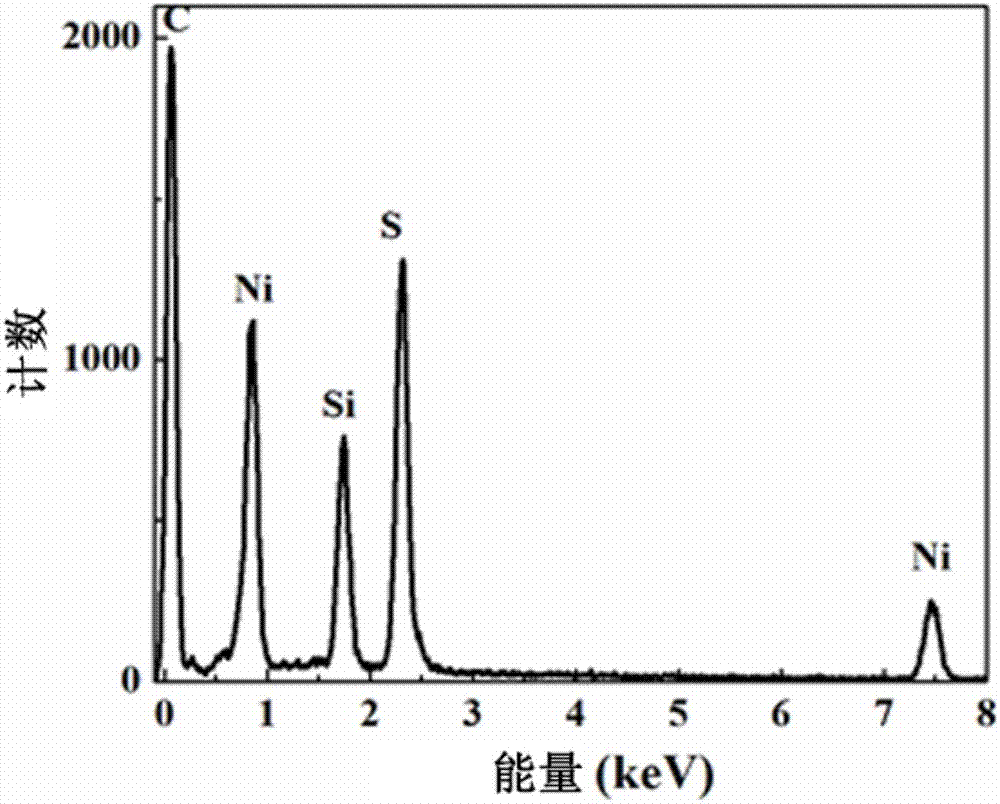

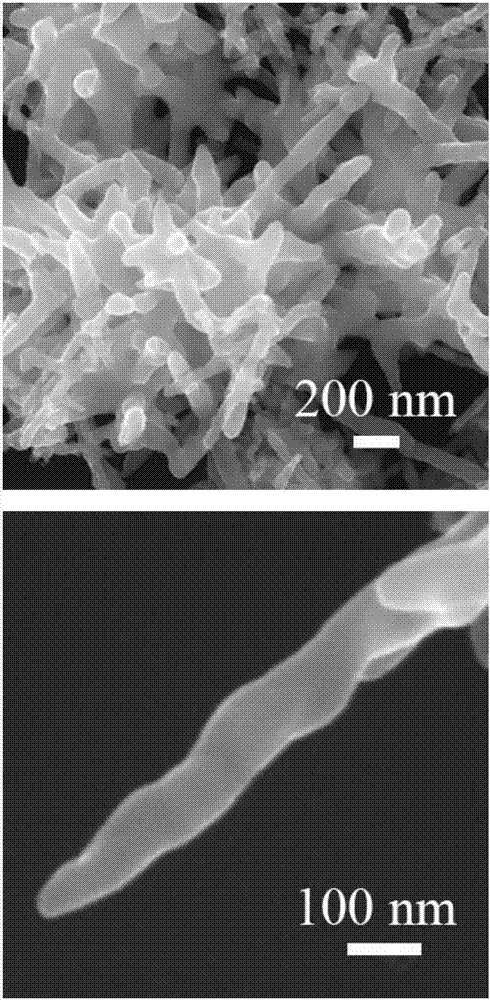

[0029] (1) Preparation of NiS by solvothermal method: Dissolve 0.4g of nickel chloride hexahydrate and 0.256g of thiourea in 33ml of absolute ethanol, stir for 10-20min, transfer to an autoclave for heating, the heating time is 10h, and the heating temperature Centrifuge at 180°C, then centrifuge the heated reaction solution at 8500rpm for 1 minute, discard the waste liquid, add absolute ethanol and centrifuge at 8500rpm for 1 minute, and discard the waste liquid. Then add deionized water and centrifuge at 8500 rpm for 1 minute, discard the waste liquid; add absolute ethanol and centrifuge at 8500 rpm for 1 minute, discard the waste liquid; repeat five times. After drying, dry in a vacuum oven at 60°C for 24 hours to obtain rod-shaped cross-nano-NiS;

[0030] (2) Coating carbon by hydrothermal method: Dissolve 0.100g NiS and 0.618g glucose in 30ml water, ultrasonically stir for 5min for 10-20min, transfer to an autoclave for heating, heating time is 3h, heating temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com