A mixed material of lithium cobalt oxide and three elements and a preparing method thereof

A mixed material, three-element technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of high raw material cost, limited material performance improvement, low compaction density and energy density, etc., and meet the requirements of preparation equipment low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

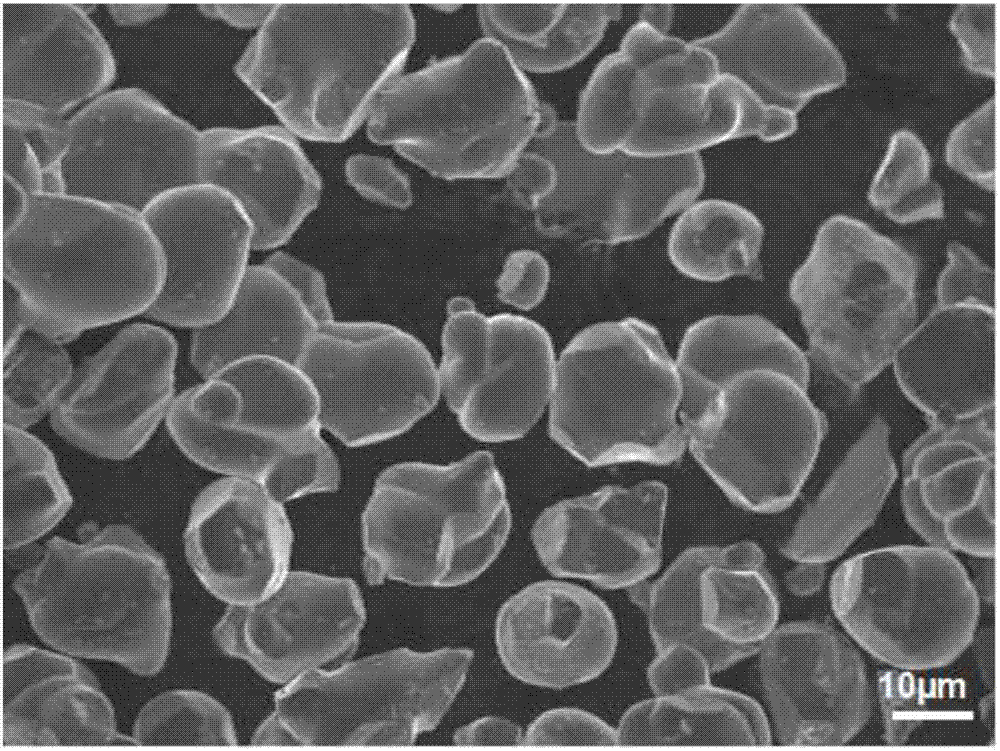

[0047] Design Li 1.08 co 0.90 al 0.10 o 2 Average D50 for large particles = 19.4 μm. Li is calculated according to the Horsfield model 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 The average D50 range of small particles is 0-8.0μm, the design Li 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 Average D50 for small particles = 8.0 μm.

[0048] According to the chemical formula Li 108 co 090 al 010 o 2 The molar ratio of cobalt oxyhydroxide and nano aluminum oxide is weighed and placed in a ball mill jar, the mass ratio of the ball to material is 2:1, ball milled for 3 hours, and mixed uniformly.

[0049] According to the chemical formula Li 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 Weigh the three-element hydroxide and ammonium metatungstate and place them in a ball mill tank with a mass ratio of ball to material of 2:1, ball mill for 3 hours, and mix well.

[0050] According to the chemical formula 0.50Li 1.08 co 0.90 al 0.10 o 2 0.50 Li 1.02 Ni 0.33 co 0.33...

Embodiment 2

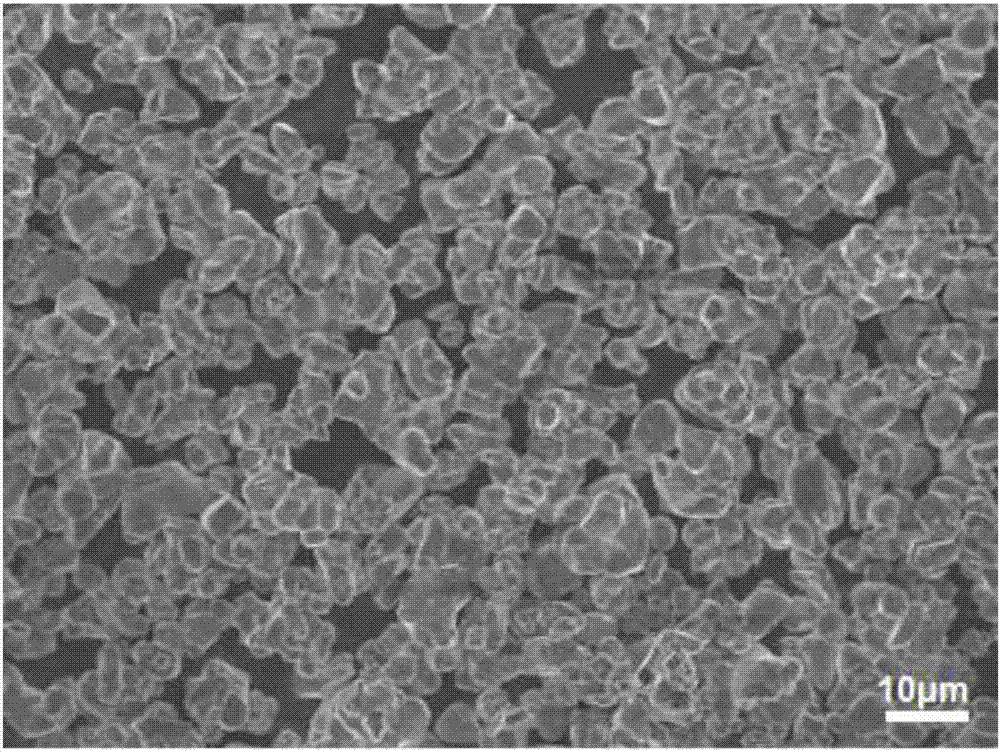

[0052] Design Li 1.08 co 0.90 al 0.10 o 2 Average D50 for large particles = 19.4 μm. Li is calculated according to the Horsfield model 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 The average D50 range of small particles is 0-8.0μm, the design Li 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 Average D50 for small particles = 8.0 μm.

[0053] According to the chemical formula Li 1.08 co 0.90 al 0.10 o 2 The molar ratio of cobalt oxyhydroxide and nano aluminum oxide is weighed and placed in a ball mill jar, the mass ratio of the ball to material is 2:1, ball milled for 3 hours, and mixed uniformly.

[0054] According to the chemical formula Li 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 Weigh the three-element hydroxide and ammonium metatungstate and place them in a ball mill tank with a mass ratio of ball to material of 2:1, ball mill for 3 hours, and mix well.

[0055] According to the chemical formula 0.60Li 1.08 co 0.90 al 0.10 o 2 0.40 Li 1.02 Ni 0.33 co 0...

Embodiment 3

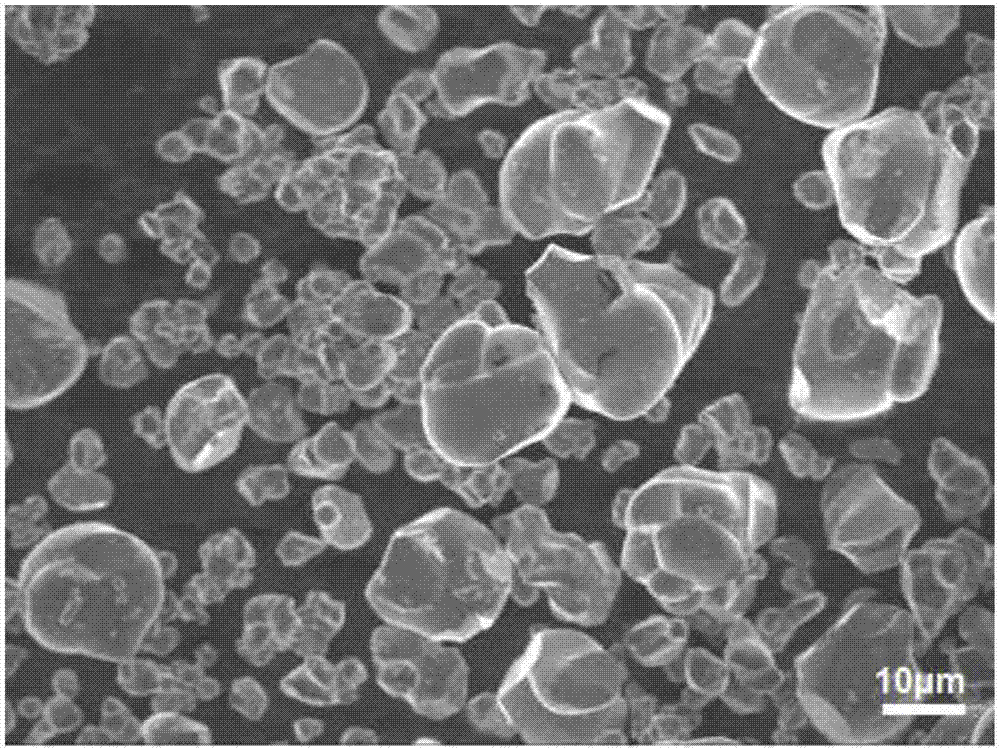

[0057] Design Li 1.08 co 0.90 al 0.10 o 2 Average D50 for large particles = 19.4 μm. Li is calculated according to the Horsfield model 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 The average D50 range of small particles is 0-8.0μm, the design Li 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 Average D50 for small particles = 8.0 μm.

[0058] According to the chemical formula Li 1.08 co 0.90 al 0.10 o 2 The molar ratio of cobalt oxyhydroxide and nano aluminum oxide is weighed and placed in a ball mill jar, the mass ratio of the ball to material is 2:1, ball milled for 3 hours, and mixed uniformly.

[0059] According to the chemical formula Li 1.02 Ni 0.33 co 0.33 mn 0.33 W 0.01 o 2 Weigh the three-element hydroxide and ammonium metatungstate and place them in a ball mill tank with a mass ratio of ball to material of 2:1, ball mill for 3 hours, and mix well.

[0060] According to the chemical formula 0.70Li 1.08 co 0.90 al 0.10 o 2 0.30 Li 1.02 Ni 0.33 co 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com