Device for testing absorption heat of solution by adopting synchronous heat tracing method and testing method

A solution absorption and heat tracking technology, applied in the direction of thermal development of materials, can solve the problems of heat dissipation, large sample size, complicated operation, etc., and achieve the effect of ensuring rapid heating, promoting stirring effect, and high control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

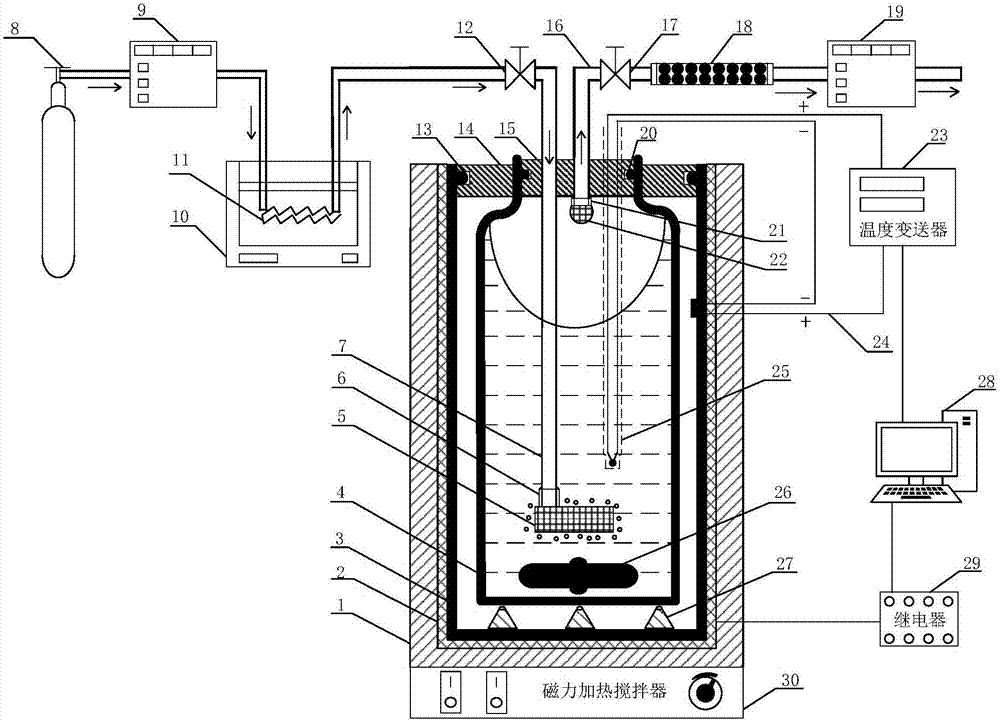

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The embodiment of the present invention measures the absorption heat of the absorption reaction between carbon dioxide gas and alcohol amine solution. The inner tube 4 is a quartz tube with an inner diameter of 250 mm, a height of 80 mm, and a wall thickness of 1.5 mm. The inner tube 4 is filled with 15 mL of solution. The outer tube 3 is a quartz tube with an inner diameter of 350 mm and a height of 85 mm. The inner tube 4 and the outer tube 3 are quartz tubes to prevent the measured liquid from being a corrosive liquid, and the diameter of the inner tube 4 is reduced to reduce heat loss caused by the tube opening. The solution temperature measuring thermocouple 25 is an armored K-type thermocouple, so that the solution temperature measuring ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com