Cylindrical battery case cutting method

A battery shell and cylindrical battery technology, which is applied in battery recycling, waste collector recycling, laser welding equipment, etc., can solve problems such as loud noise, cell expansion, and cell ejection cannot be guaranteed, so as to reduce consumption and benefit maximized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

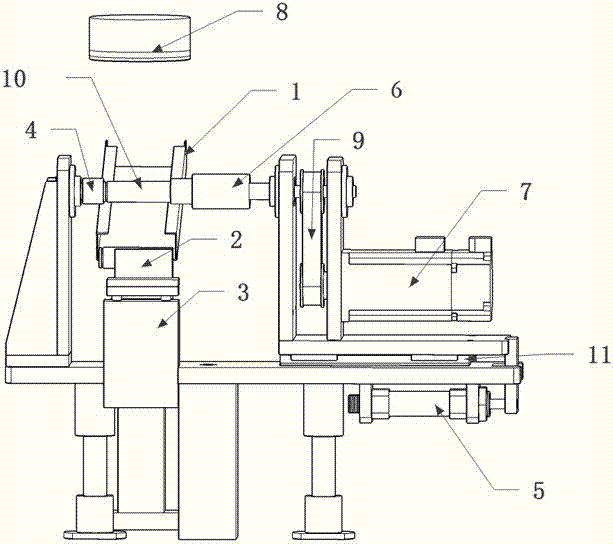

[0026] The 18650 lithium battery (diameter 18mm, height 65mm) is slid to the battery sensing position through the chute. The sensor of the sensing battery detects the battery signal, and the lifting cylinder pushes the battery sensing position up, raising the battery to the clamping position, and the battery is raised to the clamp Hold the position signal, clamp the cylinder action, clamp the battery and give the clamping signal, the stepping rotating motor that gets the signal drives the clamping device to drive the battery to rotate while the laser head does the cutting action, and the clamp is controlled by the program Rotation and laser cutting are carried out synchronously. First, circumscribe the two ends, cut directly through the middle, and then perform circumcision of the rest until the cutting is completed.

Embodiment 2

[0028] The nickel-metal hydride battery 2100A (diameter 17mm, height 50mm) slides to the battery sensing position through the chute. The sensor of the sensing battery detects the battery signal, and the lifting cylinder pushes the battery sensing position up, raising the battery to the clamping position, and the battery is raised to The signal of the clamping position, the clamping cylinder moves, clamping the battery and giving the clamping signal, the servo rotating motor that gets the signal drives the clamping device to drive the battery to rotate while the laser head does the cutting action, and the clamp is controlled by the program Rotation and laser cutting are performed synchronously. First, circumscribe one end, then circulate the other end, and finally complete direct cutting.

Embodiment 3

[0030] The No. 5 nickel-cadmium battery (diameter 14.5mm, height 50.5mm) slides to the battery sensing position through the chute, the sensor of the sensing battery detects the battery signal, and the lifting cylinder pushes the battery sensing position up, and the battery is raised to the clamping position. The signal that the battery rises to the clamping position, the clamping cylinder moves, clamping the battery and giving a clamping signal, the stepping rotating motor that receives the signal drives the clamping device to drive the battery to rotate, and the laser head does the cutting action. The rotation of the program-controlled fixture is synchronized with the laser cutting. First, circular cutting is performed at both ends, interspersed to cut directly, and then the rest of the circular cutting is performed. After the circular cutting is completed, a straight line cutting is performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com