Sorting equipment with high sorting efficiency

A high-efficiency, high-equipment technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of high input cost and operating cost, low applicability, and non-universal use, and achieve low input cost and operating cost. Simple, Efficiency-Enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

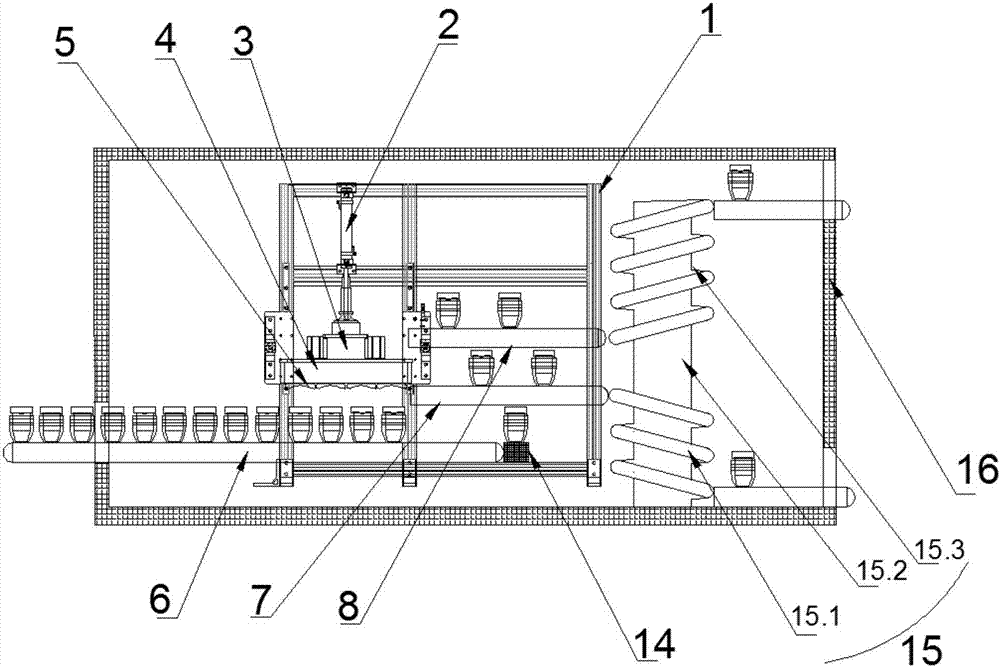

[0021] Such as figure 1 As shown, a sorting equipment with high sorting efficiency includes a hollow housing 16, and the housing 16 is provided with a bracket 1, an empty bottle grip 4 and a conveying device 15, and the bottom of the empty bottle grip 4 is A plurality of grippers 5 are provided, and the distance between the grippers 5 is consistent with that of the empty bottles. A drive motor 3 is arranged above the gripper 4 of the empty bottles, and a cylinder 2 is connected above the drive motor 3. The cylinder 2 2. The other end is connected to the top of the bracket 1. The bracket 1 is provided with a filling layer 6, a half-filling layer 7 and an empty bottle layer 8 in sequence from bottom to top. One side of the filling layer 6 is provided with a rotation axis 14. The semi-filled layer 7 and the empty bottle layer 8 can move left and right, and the conveying device 15 includes a central rotating shaft 15.2, an upward spiral body 15.3 located above the central rotating...

Embodiment 2

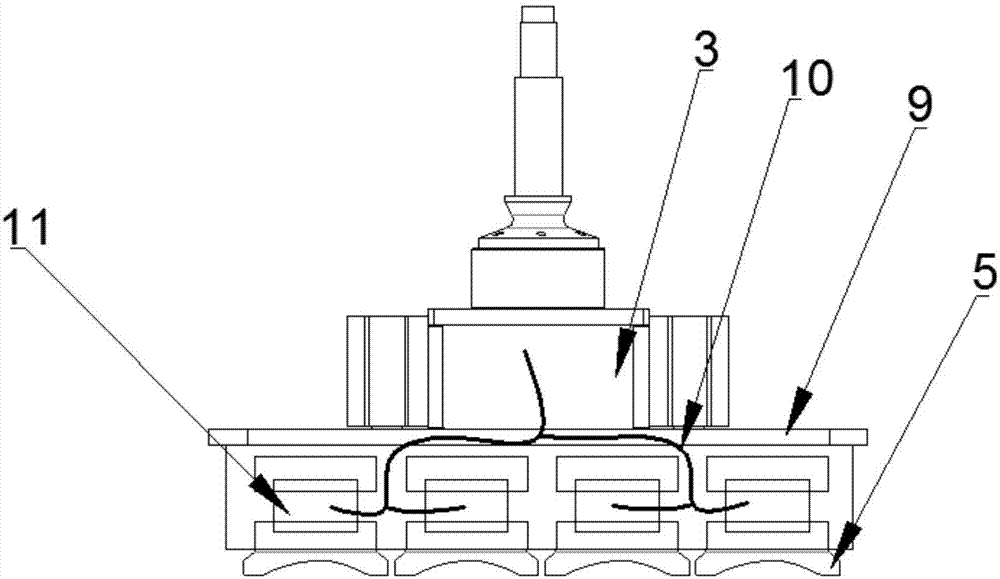

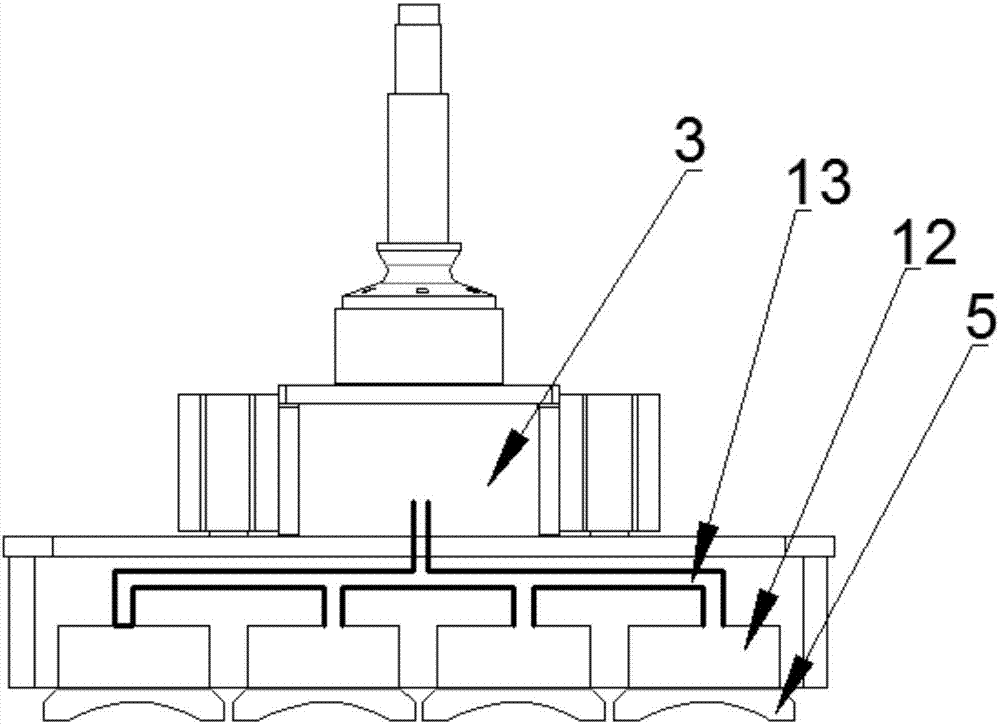

[0025] As a special case of embodiment one hollow bottle gripper, as figure 2 As shown, the empty bottle gripper 4 in the first embodiment includes a top cover 9, and a plurality of concave spaces are arranged between the bottom of the top cover 9 and the top of the gripper 5, and the spaces are sequentially arranged from bottom to top. Magnetic connection plate, strong magnet, magnetic substrate, the strong magnet is located on the magnetic substrate, a cylinder b11 is arranged between the magnetic substrate and the magnetic connection plate, and the cylinder b11 is connected to the drive motor 3 with an air pump through the air pipe a10.

[0026] The driving motor 3 with an air pump controls the pressure of the cylinder b11, thereby controlling the distance between the magnetic base plate and the magnetic joint plate, achieving the purpose of controlling the magnetic force of the magnetic joint plate, and finally controlling the suction force of the magnetic joint plate on t...

Embodiment 3

[0028] In order to further optimize the grasping effect of the packaging bottle in the second embodiment, the strong magnet described in the second embodiment is a neodymium-iron-boron supermagnet, which can enhance the efficiency of grasping the packaging bottle. Neodymium iron boron (NdFeB) is the most powerful permanent magnet among contemporary magnets. It not only has the characteristics of high remanence, high coercive force, high magnetic energy product, high performance and price ratio, but also is easy to process into various sizes. Widely used in aviation, aerospace, electronics, electro-acoustic, electromechanical, instruments, meters, packaging, toys, medical technology and other devices and equipment that require permanent magnetic fields, especially suitable for the development of high-performance, miniaturized and light-weight various A replacement product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com