Double-station bent arm connecting rod motor structure

A double-station, electric motor technology, applied in other household appliances, household appliances, applications, etc., can solve the problems of low output efficiency of blow molding, time loss of invalid waiting, and inability to realize double-station cycle blow molding, etc., to achieve Compact structure, fast mold clamping and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

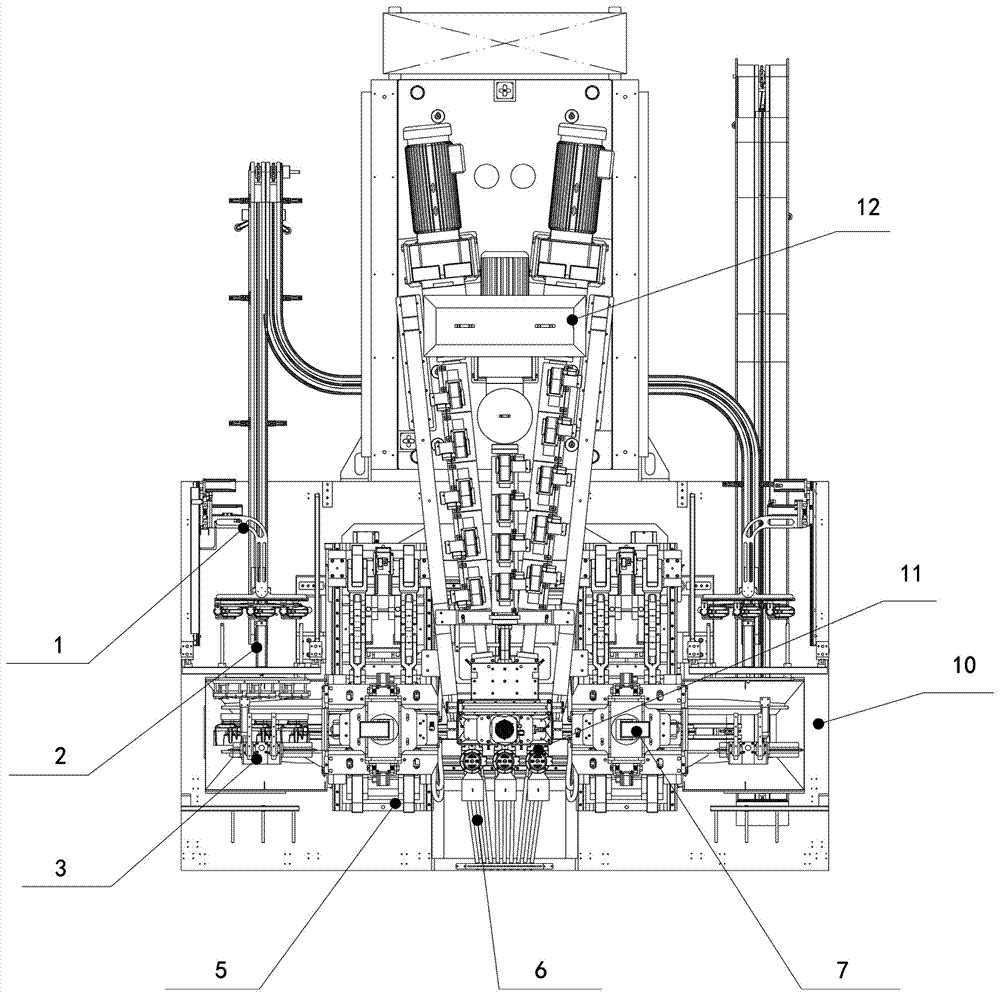

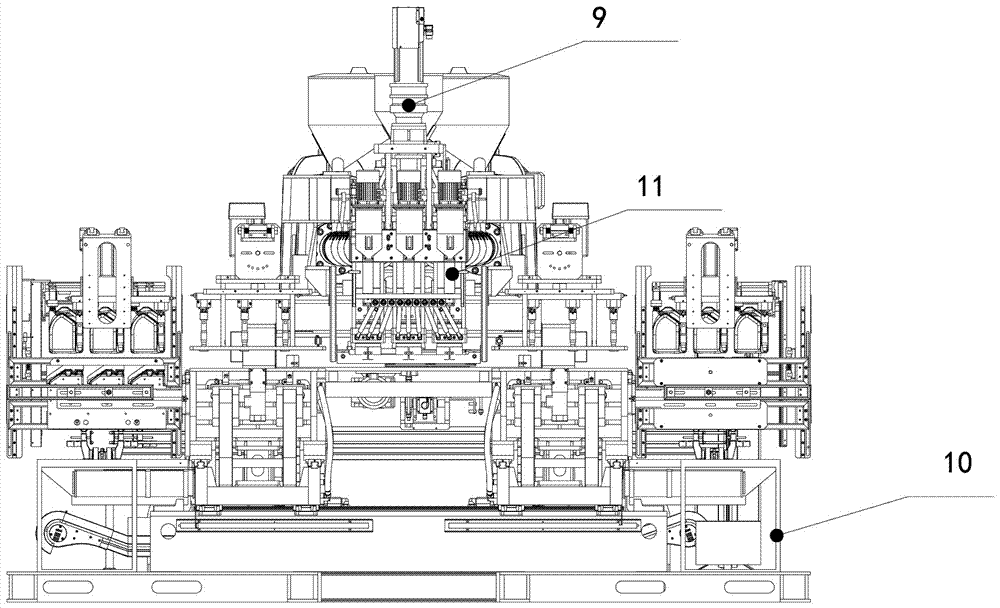

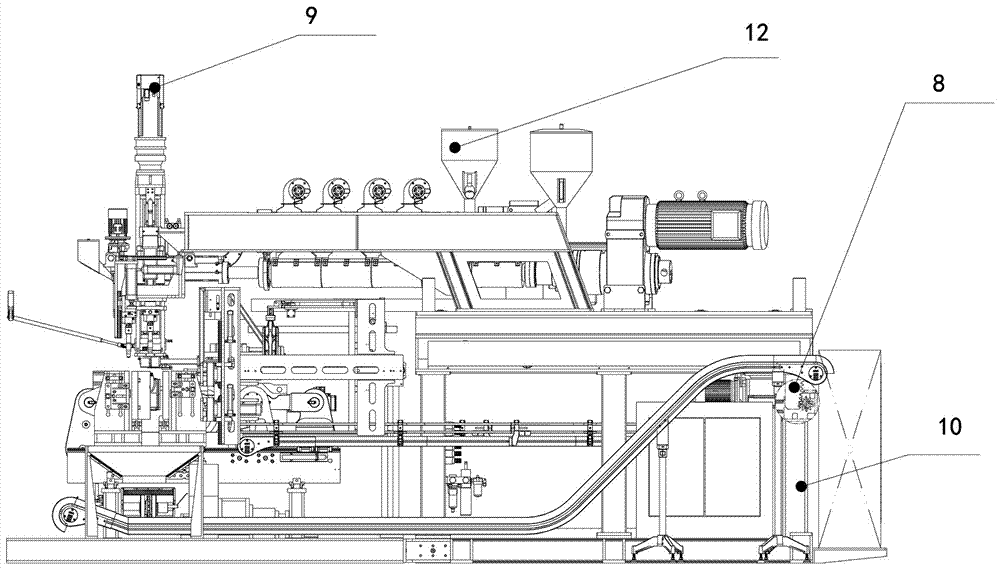

[0040] The structure of a double-station crank arm connecting rod motor described in Embodiment 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a frame workbench 10, an extruder 12 with an extruder head 11 is arranged on the frame workbench, and a blow molding mechanism with double stations and the same structure is arranged symmetrically on the left and right sides of the extruder; The blow molding mechanism includes a mold clamping device 5 that can move in and out of the center of the extruder head to realize mold clamping, mold removal and film change, and also includes a mold clamping device that can blow the liquid glue after injecting the mold and moving the mold. Air-forming blowing seat device 7. The secondary sizing device installed on the blowing seat device for secondary sizing of the formed product by cold air 3. Set on the workbench of the machine frame to sizing the formed product after the secondary sizing of the cold air Mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com