Super-hydrophobic transparent glass and preparation method thereof

A transparent glass and super-hydrophobic technology, which is applied to the surface of super-hydrophobic and high-transparency glass and its preparation, and the field of super-hydrophobic and high-transparency glass and its preparation. Low efficiency and other problems, to achieve the effect of good superhydrophobicity, self-sturdy, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of superhydrophobic transparent glass preparation method that the present invention proposes, its specific steps are as follows:

[0026] 1) Ultrashort pulse laser is used to ablate discrete point-like pits on the glass surface; the ultrashort pulse laser is femtosecond laser or picosecond laser; the glass can be ordinary glass or quartz glass.

[0027] 2) Perform multiple variable-energy laser pulse processing on each point-shaped small pit, so that the pit presents a self-assembled micro-nano structure formed by multiple scanning superimpositions; The number of treatments is generally 1-3 times, and the energy of the laser pulse can be increased or decreased in a gradient; after multiple variable energy treatments, the small pit presents a rich micro-nano structure formed by multiple scanning superimpositions, which improves the micro-nano-level roughness in the pit , to improve superhydrophobic properties;

[0028] 3) Low free energy surface treatment is carr...

Embodiment 1

[0034] In this embodiment, a high-power femtosecond laser with energy gradient changes is used to prepare a super-hydrophobic transparent quartz glass surface through multiple direct writing, including the following steps:

[0035] 1), the preparation of quartz glass: carry out ultrasonic cleaning to quartz glass with alcohol and acetone, dry and set aside;

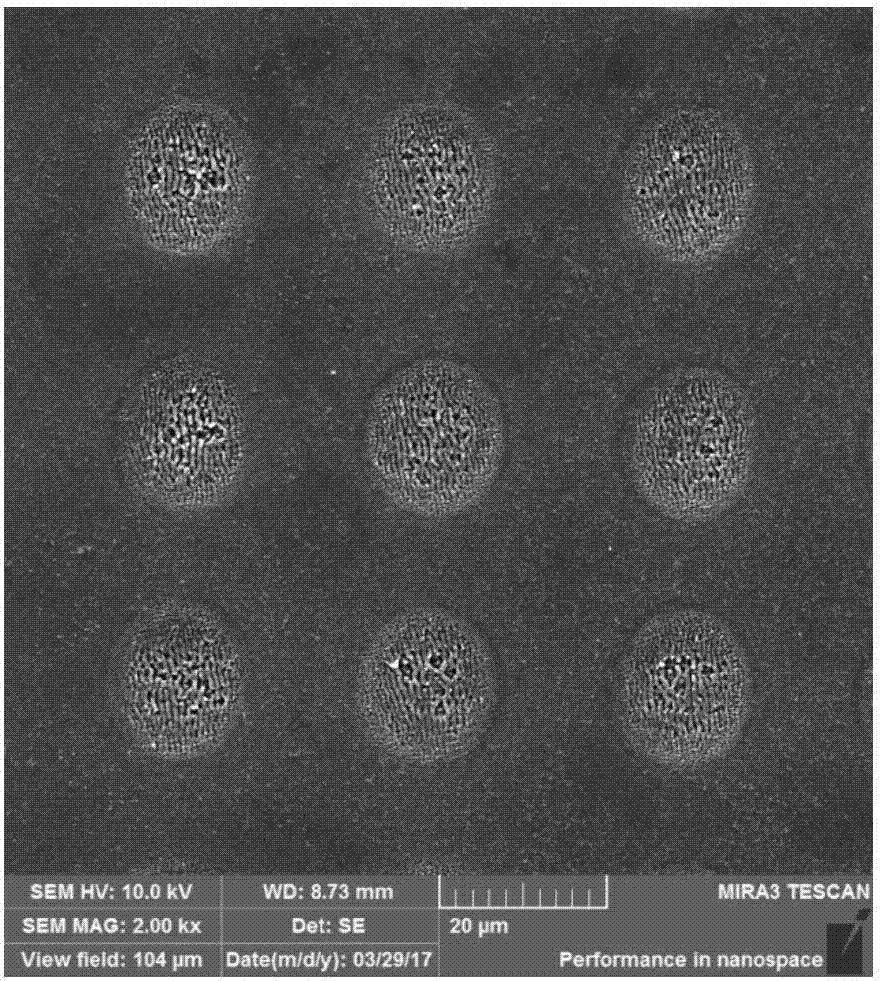

[0036] 2) Laser processing: using high-power femtosecond laser, combined with X-Y scanning galvanometer, ablate the same dot matrix pattern on the same glass surface three times, each time using laser energy with different energy flux density to ablate the glass surface, forming a The periodic pit structure of submicron stripes and nanoparticles, the pit diameter is 20 microns, the depth is 1 micron, and the spacing is 30 microns, the inner surface of the micron-scale pits is distributed with a period of about 500 nanometers. Particles, scanning electron micrographs of micro-nanostructures on the glass surface are shown i...

Embodiment 2

[0039] In this embodiment, a high-power femtosecond laser is used to prepare a superhydrophobic transparent quartz glass surface at one time, including the following steps:

[0040] 1), the preparation of quartz glass: carry out ultrasonic cleaning to quartz glass with alcohol and acetone, dry and set aside;

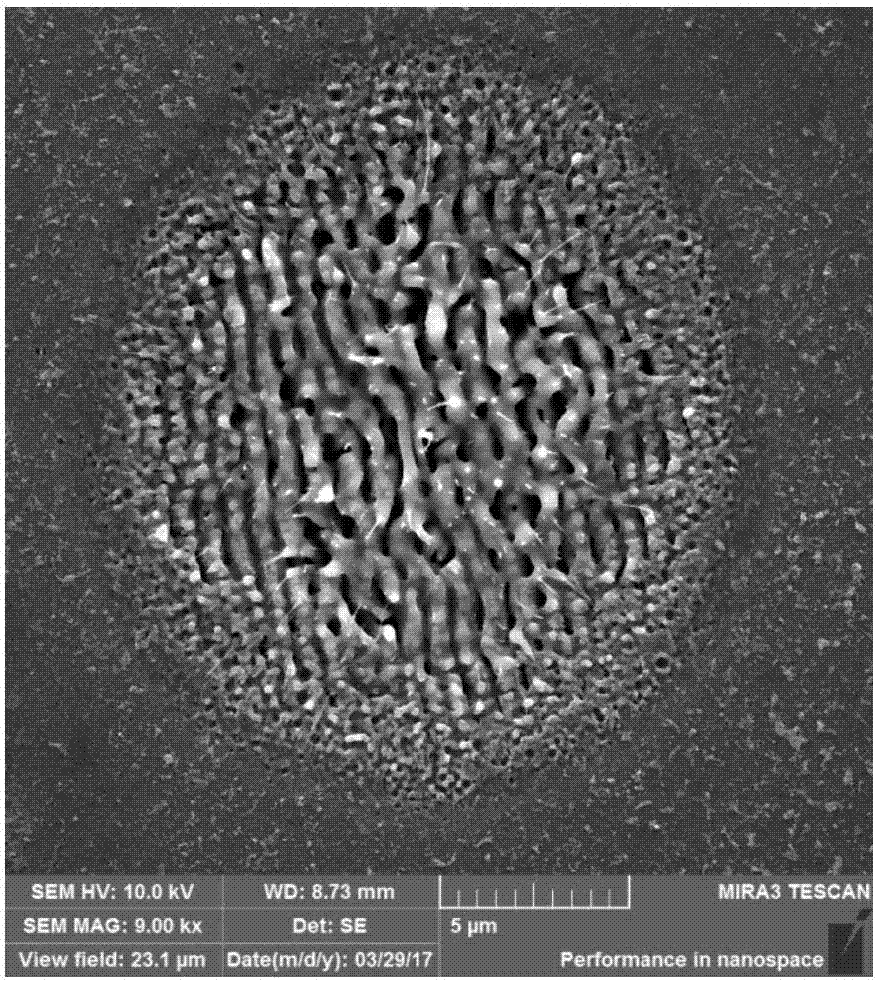

[0041] 2) Laser processing: Using high-power femtosecond laser, combined with X-Y scanning galvanometer, by setting the laser processing time, multiple equal pulse laser energies are applied to the same pit at the same time, and ablation with submicron on the glass surface at one time The periodic point pit structure of the stripes, the pit diameter is 20 microns, the depth is 2-4 microns, and the spacing is 30 microns. There are a large number of irregular corrugated substructures distributed on the inner surface of the micron-scale point pits. The micro-nano structure of the obtained glass surface Scanning electron microscope photos as Figure 5 shown.

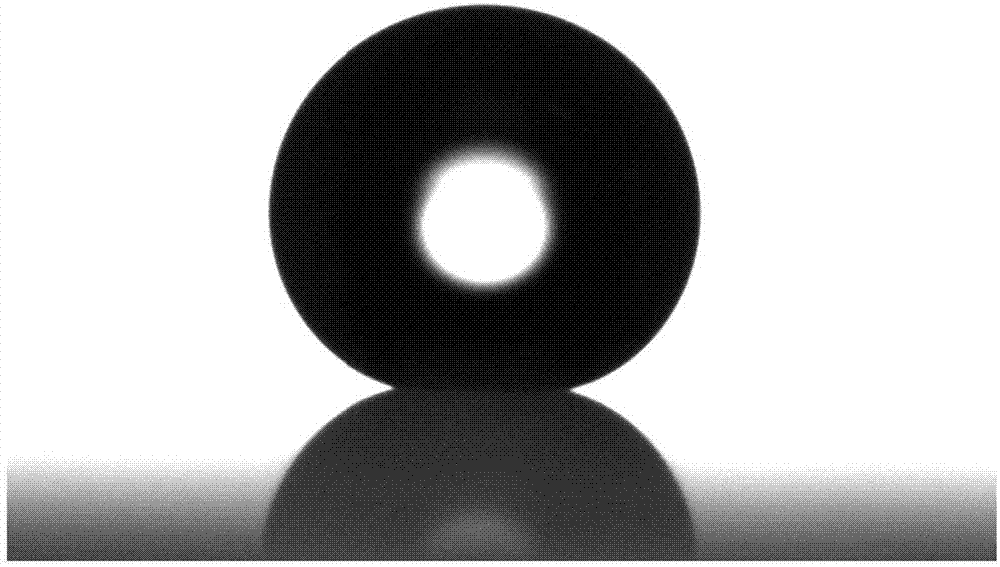

[0042] Using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com