Preparation method for conductive wear-resistant butadiene-acrylonitrile rubber material

A kind of technology of nitrile rubber and preparation steps, which is applied in the field of preparation of conductive and wear-resistant nitrile rubber materials, can solve the problems of poor electrical conductivity and easy wear of rubber, and achieve the effects of improving adhesion, broad application prospects, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

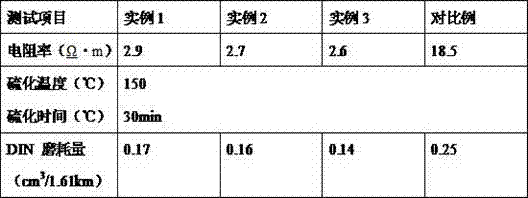

example 1

[0023] Weigh 20g expandable graphite and place it in a vacuum drying oven, set the temperature of the vacuum drying oven to 100℃, put 100g phosphorus pentoxide in the vacuum drying oven, dry for 8 hours, and put the dried expandable graphite into a beaker , Then put the beaker under the microwave and process it with 700W power for 40s, take out the beaker and cool to room temperature to expand the expandable graphite, so the microwave treatment heats and expands 3 times to obtain expanded graphite; combine 20g of sodium lauryl sulfate with Mix 200 mL of deionized water and stir for 10 minutes to obtain an emulsion. Soak 10 g of expanded graphite in the emulsion to obtain a mixed suspension. Perform ultrasonic treatment on the mixed suspension. Set the ultrasonic frequency to 30KHz. After ultrasonic treatment, nano graphite flakes are obtained. The aqueous suspension of the layer; add 100g of acrylonitrile and 90g of butadiene into a three-necked flask with a stirrer and a thermo...

example 2

[0025] Weigh 25g of expandable graphite and place it in a vacuum drying oven. Set the temperature of the vacuum drying oven to 105°C. Put 110g of phosphorus pentoxide into the vacuum drying oven and dry for 9 hours. Put the dried expandable graphite into a beaker. , Then put the beaker in the microwave for 42s with a power of 750W, take out the beaker and cool to room temperature to expand the expandable graphite, so the microwave treatment heats and expands 4 times to obtain expanded graphite; combine 23g of sodium lauryl sulfate with Mix 210mL of deionized water and stir for 13 minutes to obtain an emulsion. Soak 13g of expanded graphite in the emulsion to obtain a mixed suspension. The mixed suspension is subjected to ultrasonic treatment, and the ultrasonic frequency is set to 31KHz. After ultrasonic treatment, nano graphite flakes are obtained The aqueous suspension of the layer; add 105g acrylonitrile and 95g butadiene into a three-necked flask with a stirrer and a thermom...

example 3

[0027] Weigh 30g of expandable graphite and place it in a vacuum drying oven. Set the temperature of the vacuum drying oven to 110°C. Put 120g of phosphorus pentoxide in the vacuum drying oven and dry for 10 hours. Put the dried expandable graphite into a beaker. , Then put the beaker under the microwave and treat it with 800W power for 45s, take out the beaker and cool it to room temperature to expand the expandable graphite, so the microwave treatment heats and expands 5 times to obtain expanded graphite; combine 25g of sodium lauryl sulfate with Mix 220mL of deionized water and stir for 15min to obtain an emulsion. Soak 15g of expanded graphite in the emulsion to obtain a mixed suspension. The mixed suspension is subjected to ultrasonic treatment, and the ultrasonic frequency is set to 32KHz. After ultrasonic treatment, nano graphite flakes are obtained. The aqueous suspension of the layer; put 110g of acrylonitrile and 100g of butadiene into a three-necked flask with a stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com