Glass fiber reinforced PA6 composition with improved surface fiber exposing phenomenon, and preparation method thereof

A technology of composition and glass fiber, which is applied in the field of glass fiber reinforced PA6 composition and its preparation to improve the floating fiber phenomenon, can solve the problems affecting the performance of pressure-resistant parts and the appearance of PA parts, and achieve the improvement of mechanical properties. Strength, increased absorption and dissipation effects, torque reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

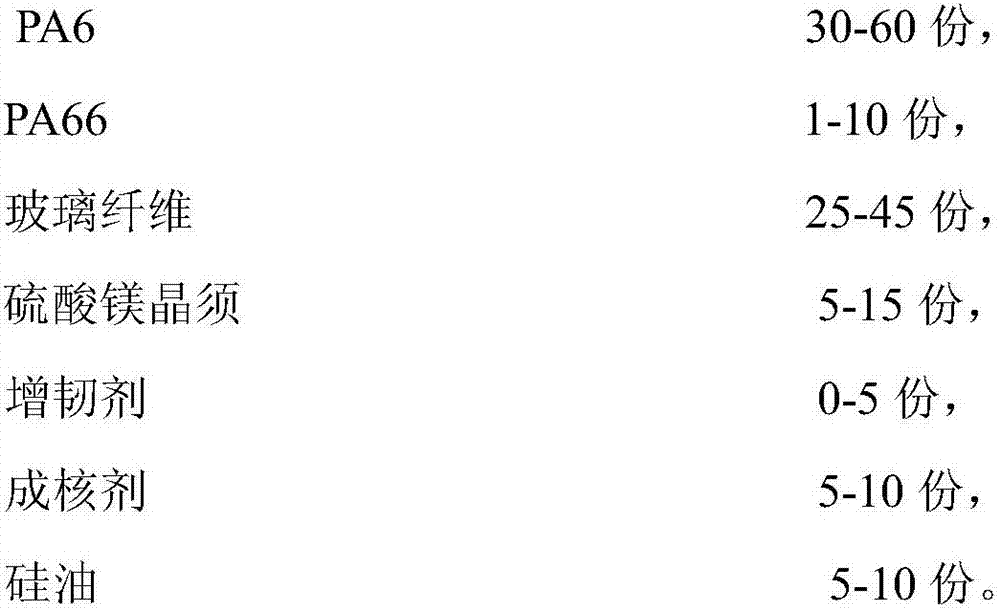

Method used

Image

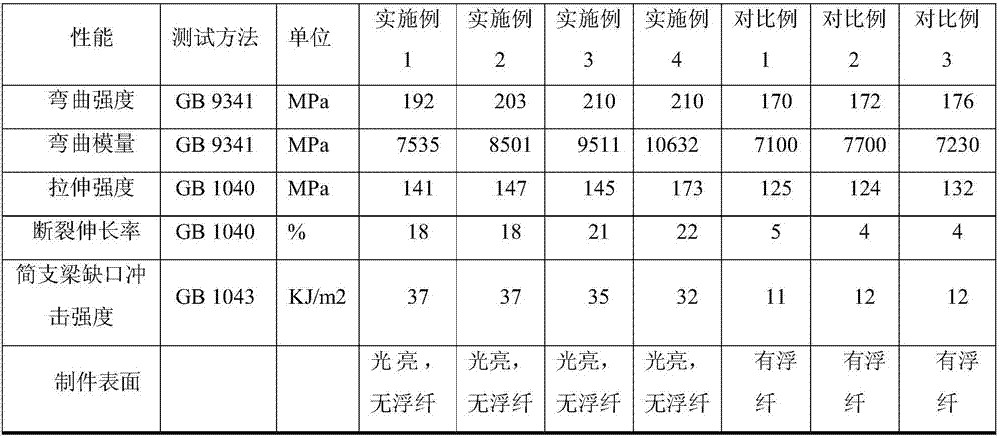

Examples

Embodiment 1

[0034] (1) Dry PA6 at 110°C for 4 hours; PA66 at 110°C for 4 hours;

[0035] (2) Take by weighing 60 parts of dry PA6, 1 part of PA66, 25 parts of glass fibers, 5 parts of magnesium sulfate whiskers, 5 parts of sodium benzoate, and 5 parts of silicone oil;

[0036] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3 minutes;

[0037] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0038] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0039] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the second zone is 245°C, the temperature of the third zone is 255°C, the temperature of the fourth zone is 265°C, the temperature of the fifth zone is 260°C, and the temperature of the sixth zone The temperature is 265°C, the head temperature is 265°C, an...

Embodiment 2

[0041] (1) Dry PA6 at 110°C for 4 hours; PA66 at 110°C for 4 hours;

[0042] (2) take by weighing dry 40 parts of PA6, 10 parts of PA66, 30 parts of glass fiber, 15 parts of magnesium sulfate whiskers, 5 parts of toughening agent maleic anhydride grafted ethylene-octene copolymer, 10 parts 10 parts of sodium benzoate, 10 parts of silicone oil;

[0043] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3 minutes;

[0044] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0045] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0046] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 220°C, the temperature of the second zone is 225°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 245°C, the temperature of the fifth zone is 240°C, and the ...

Embodiment 3

[0048] (1) Dry PA6 at 140°C for 4-5h; PA66 at 120°C for 5h;

[0049] (2) Weigh dry 40 parts of PA6, 5 parts of PA66, 35 parts of glass fiber, 10 parts of magnesium sulfate whiskers, 3 parts of toughening agent ethylene-methyl acrylate copolymer, 5 parts of sodium benzoate , 5 parts of silicone oil;

[0050] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3 minutes;

[0051] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0052] (5) The material is melted and extruded by a twin-screw extruder, and granulated;

[0053] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 240°C, the temperature of the second zone is 255°C, the temperature of the third zone is 265°C, the temperature of the fourth zone is 275°C, the temperature of the fifth zone is 270°C, and the temperature of the sixth zone is 270°C. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com