Virgin refining-free camellia oil production method

A production method, the technology of camellia oil, is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of low oil yield by pressing method and lower nutrient content of finished oil by leaching method, so as to shorten the production cycle , improve quality and health care function, reduce the effect of high temperature refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

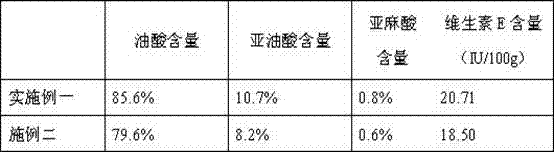

Examples

Embodiment 1

[0025] (1) Seed selection: select camellia seeds with normal color, no mildew, no impurities and plump, and dry them to obtain 1000kg of camellia seeds.

[0026] (2) Coarse crushing: the tea seeds obtained in step (1) are crushed with a crusher; in this step, the camellia seeds are broken in half with a crusher. Air selection is then carried out to remove part of the tea seed husk debris. This step obtains 945kg of mixed material of tea seed shell and tea seed kernel, wherein tea seed shell accounts for 25%, and tea seed kernel 75%.

[0027] (3) Drying: put the tea seeds obtained in step (2) into a frying pan, and stir-fry at a temperature not higher than 65°C until the water content of the tea seeds is 9%. The specific temperature is controlled at 60~65°C.

[0028] (4) Fine crushing: the material obtained in step (3) is crushed into tea seed powder; in this step, 8 kg of calcium bicarbonate is evenly added to the material to neutralize the acid value of the material.

[00...

Embodiment 2

[0036] (1) Seed selection: select camellia seeds with normal color, no mildew, no impurities and plump, and dry them to obtain 1000kg of camellia seeds.

[0037] (2) Coarse crushing: the tea seeds obtained in step (1) are crushed with a crusher; in this step, the camellia seeds are broken in half with a crusher. Carry out winnowing then, remove part of tea seed husk debris. This step obtains 942kg of mixed material of tea seed shell and tea seed kernel, wherein tea seed shell accounts for 25%, and tea seed kernel 75%.

[0038] (3) Drying: put the tea seeds obtained in step (2) into a frying pan, and stir-fry at a temperature not higher than 65°C until the water content of the tea seeds is 9%. The specific temperature is controlled at 60~65°C.

[0039] (4) Fine crushing: the material obtained in step (3) is crushed into tea seed powder; in this step, 7 kg of calcium bicarbonate is uniformly added to the material.

[0040] (5) Cake making by steaming bran: put the material ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com