A kind of method of pressure-enhanced leaching of copper fume

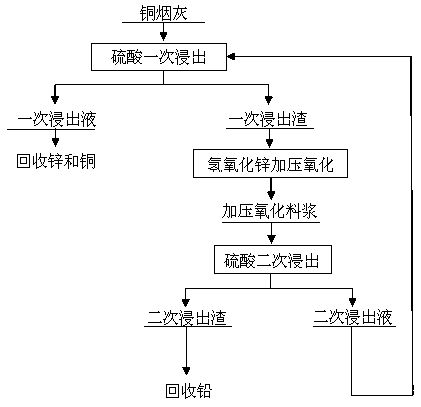

A technology for strengthening leaching and copper soot, applied in the direction of improving process efficiency, etc., can solve the problems of little research on soot treatment methods, complex composition, and difficulty in effectively leaching soot, etc., and achieve the effects of low production cost, efficient leaching, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Copper soot produced during the smelting process of a copper concentrate Osmet furnace in a domestic enterprise, its main components are (%): Cu3.37, Zn15.54, Pb28.70, As2.61 , Bi3.71, S14.72. The mass percentage of industrial grade sulfuric acid is not less than 98.0%. The mass percentage of industrial grade zinc hydroxide is not less than 99.0%, and the oxygen purity of industrial grade reagents is not less than 99.2%. Copper soot is sieved to make -0.074um account for 90%, and the ratio of the volume L of water to the mass kg of copper soot is 3:1, add water to make slurry, add sulfuric acid to control the pH value of the slurry to 1.5, and keep the slurry temperature at 80 ℃ and rotating speed 200r / min, react for 1.5h, and use plate and frame filter press to achieve solid-liquid separation to obtain primary leaching slag and primary leaching liquid after the reaction is completed. The slag rate obtained in the primary leaching process is 64.06%. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com