Mid-infrared pulsed laser device

A pulsed laser and infrared technology, applied in the laser field, can solve the problems of poor functional ductility, high system cost, difficult ultra-short pulse laser output, etc., and achieve the effects of low cost, simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

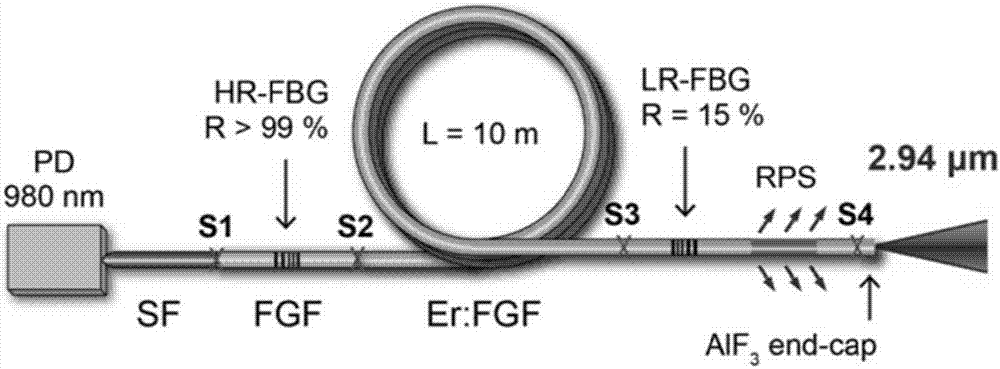

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

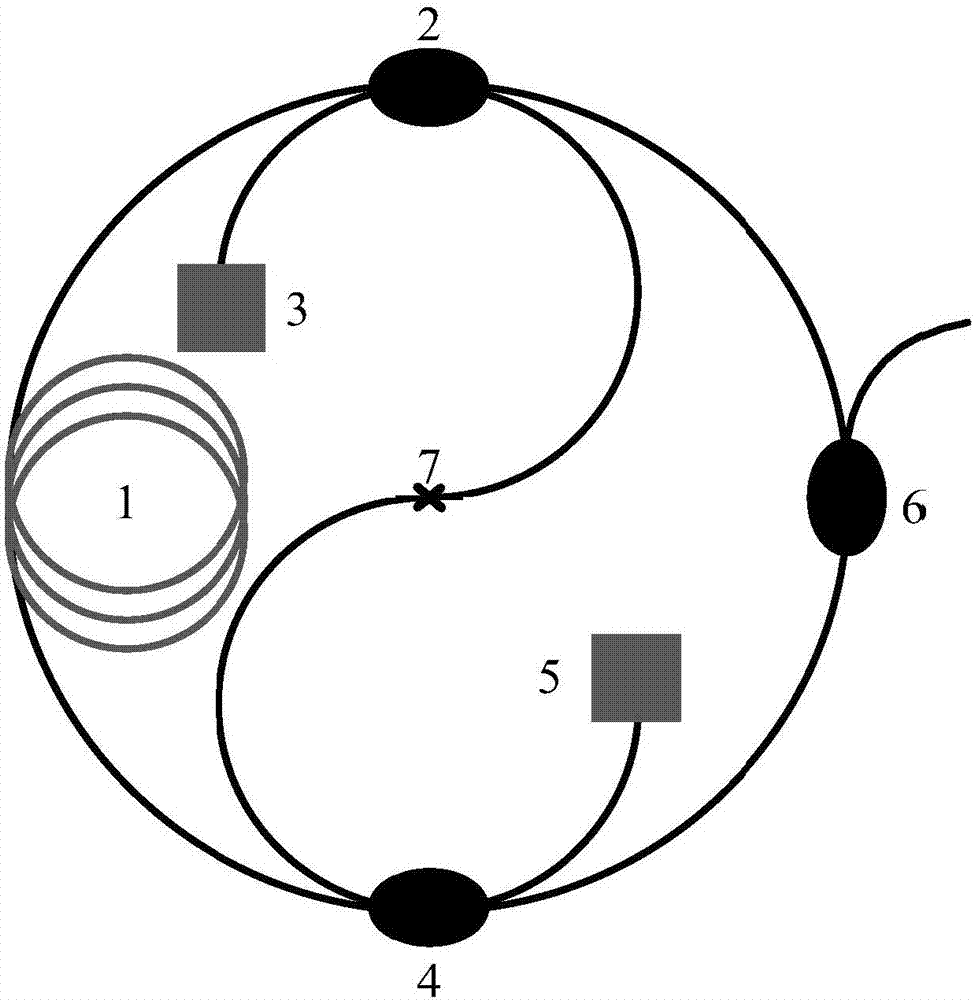

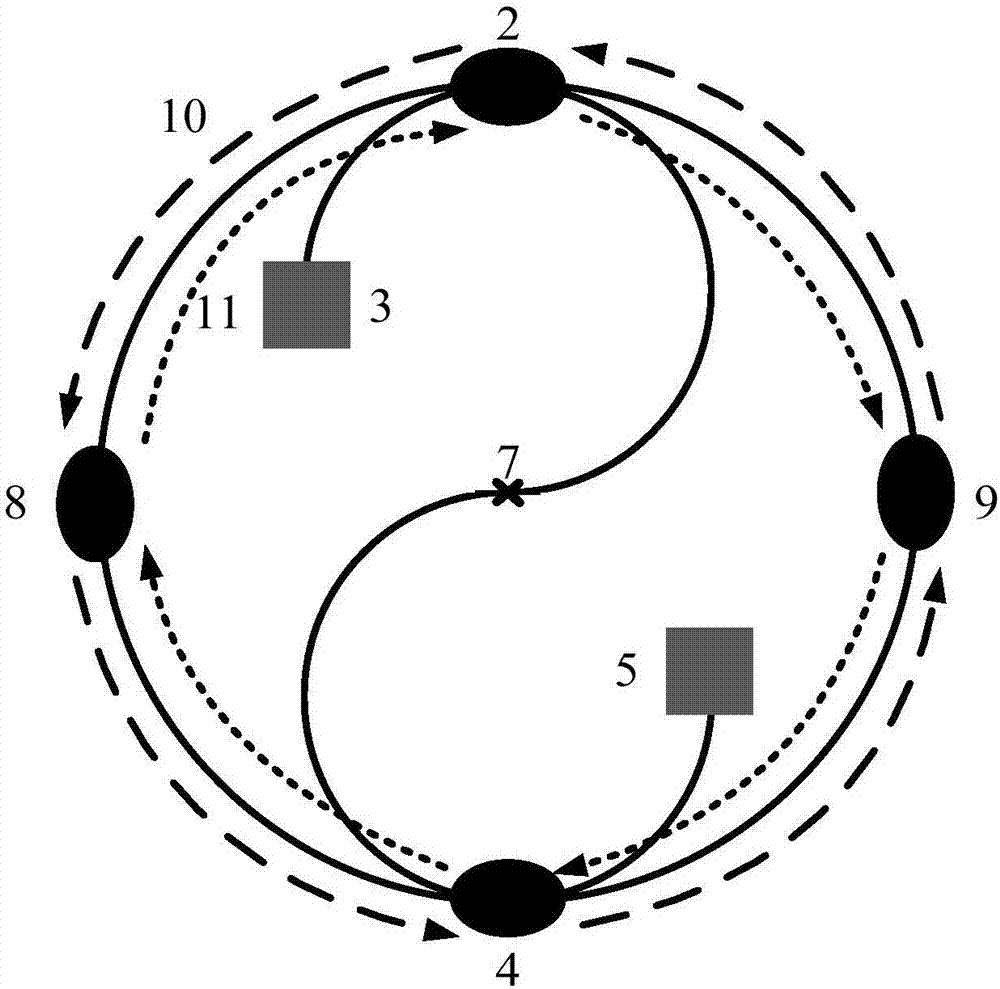

[0024] Such as figure 2 Shown is a schematic structural diagram of a mid-infrared laser according to an embodiment of the present invention, including a THETA resonator, and the THETA resonator is in the shape of a ring; specifically, it includes: a first fluoride fiber coupler 2, a second fluoride fiber coupler 4, Amplifying unit 1 and fluoride output coupler 6;

[0025] The first end of the amplifying unit 1 is connected with the pigtail at the first end of the first fluoride fiber coupler 2; the second end of the amplifying unit 1 is connected with the pigtail at the first end of the second fluoride fiber coupler 4; the The first end of the fluoride output coupler 6 is connected with the pigtail at the second end of the first fluoride fiber coupler 2; the second end of the fluoride output coupler 6 is connected with the pigtail at the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com