Tube bus split wire clip

A technology of splitting wires and pipe busbars, which is applied in the direction of open busbar installation, etc., can solve the problems of mechanical wear, magnetic loss, eddy current flux ring, etc., prevent tip discharge, improve contact and grip force, and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

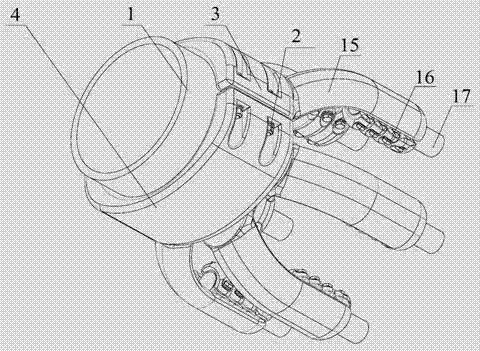

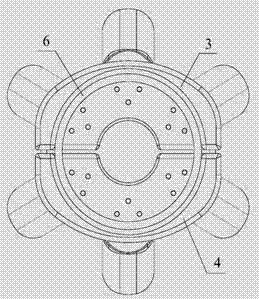

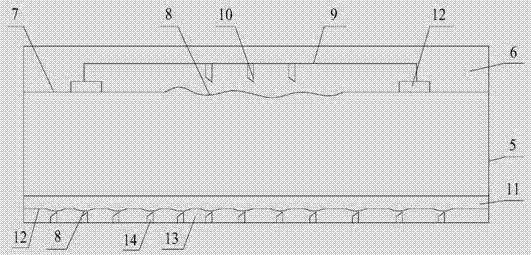

[0036] Combined with the manual figure 1 — image 3 , the present invention is a pipe busbar split wire clamp, including a pipe busbar clamp sleeved on the surface of the tubular busbar 1 and a plurality of flexible wire clamps for splitting wires arranged on one side of the pipe busbar clamp. The busbar clamp includes a first pipe busbar clamp 3 and a second pipe busbar clamp 4 that are symmetrically connected by fastening bolts 2 at both ends. The first pipe busbar clamp 3 and the second pipe busbar clamp 4 are equipped with reinforcement devices, so The reinforcement device includes a gas-generating chamber 5 filled with ammonium bicarbonate, an airbag 6 placed on the top of the gas-generating chamber 5, and a temperature control structure located at the bottom of the gas-generating chamber 5. The gas-generating chamber 5 is respectively embedded in The first pipe bus clamp 3 and the second pipe bus clamp 4 are inside and surround the outer circumference of the tubular bus...

Embodiment 2

[0040] Combined with the manual figure 1 — Figure 4 , except that the number of flexible wire clamps is set to three, and the tubular busbar 1 is vertically connected with the tubular busbar clamps, the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com