Anhydrous foaming aerosol for removing makeup

A water foaming and aerosol technology, applied in skin care preparations, cosmetics, cosmetics, etc., can solve the problems of poor solubility of oily substances, incomplete removal of makeup, easy dripping of massage oil, etc., and achieve makeup removal ability Strong, rich and long-lasting foam, good foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method for anhydrous foaming aerosol for makeup removal:

[0045]

[0046] a. According to the above mass percentage content, weigh a total of 60% emollient oil of olive oil, camellia seed oil, jojoba oil, and squalane, stir with an IKA mixer at 500rpm for 10-20 minutes, and stir evenly to obtain phase A ;

[0047] b. According to the above mass percentage, weigh polyglyceryl-2 laurate, polyglycerol-5 trioleate, and lipopeptide sodium, add phase A in sequence, heat to 55°C, and stir with an IKA stirrer at 800rpm 20-30 minutes, stir until completely dissolved to obtain phase B;

[0048] c. According to the above mass percentage content, weigh tocopherol, BHT, and tocopheryl acetate with a total of 1% antioxidants, add phase B in sequence, heat to 75-80°C, and stir with an IKA stirrer at 500rpm for 20-30 Minutes, stir until completely dissolved, then cool down to 35°C with stirring. Get phase C;

[0049] d, filter the discharge with a 100 mesh stainle...

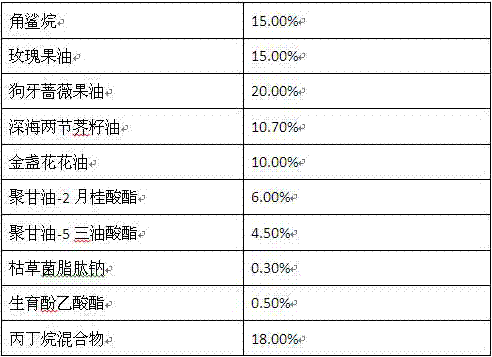

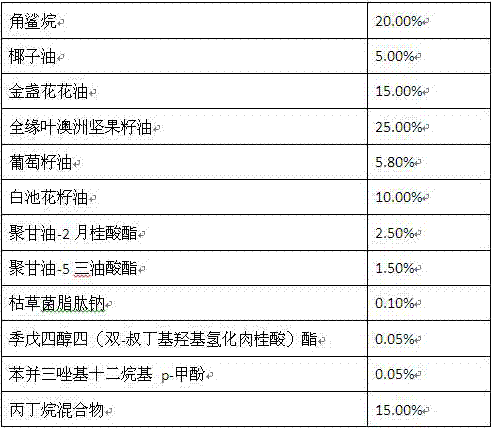

Embodiment 2

[0052] A preparation method for anhydrous foaming aerosol for makeup removal:

[0053]

[0054] a. According to the above mass percentage content, weigh squalane, coconut oil, calendula flower oil, whole margin leaf macadamia nut seed oil, grape seed oil, white pond flower seed oil and a total of 80.8% emollient oil, stir with IKA Stir at 500 rpm for 10-20 minutes, stir evenly, and obtain phase A;

[0055] b. According to the above mass percentage, weigh polyglyceryl-2 laurate, polyglycerol-5 trioleate, and lipopeptide sodium, add phase A in sequence, heat to 55°C, and stir with an IKA stirrer at 800rpm 20-30 minutes, stir until completely dissolved to obtain phase B;

[0056] c. According to the above mass percentage content, take pentaerythritol tetrakis (bis-tert-butyl hydroxyhydrogenated cinnamate) ester and benzotriazolyl dodecyl p-cresol as a total of 0.1% antioxidant, and add B phase, heated to 75-80°C, stirred with an IKA stirrer at 500rpm for 20-30 minutes, stirr...

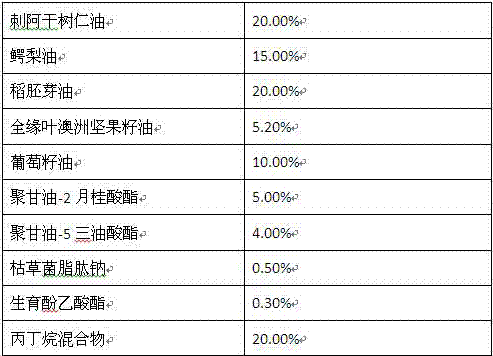

Embodiment 3

[0060] A preparation method for anhydrous foaming aerosol for makeup removal:

[0061]

[0062] a, according to the above mass percentage content, take argan tree kernel oil, avocado oil, rice germ oil, whole margin leaf macadamia nut seed oil, grape seed oil a total of 70.2% emollient oil, with IKA stirrer 500rpm Stir for 10-20 minutes, stir evenly, and obtain phase A;

[0063] b. According to the above mass percentage, weigh polyglyceryl-2 laurate, polyglycerol-5 trioleate, and lipopeptide sodium, add phase A in sequence, heat to 55°C, and stir with an IKA stirrer at 800rpm 20-30 minutes, stir until completely dissolved to obtain phase B;

[0064] c. According to the above mass percentage, weigh tocopheryl acetate, add phase B, heat to 70-75°C, stir with IKA stirrer at 500rpm for 20-30 minutes, stir until completely dissolved, then stir and cool down to 35°C . Get phase C;

[0065] d, filter the discharge with a 100 mesh stainless steel filter;

[0066] e, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com