A method for preparing metal foam from coke composite blowing agent

A composite foaming agent and metal foam technology, applied in the field of preparation of new metal materials, can solve the problems of long process, cumbersome operation, slow deposition speed, etc., achieve good mechanical properties, simple preparation process, and prevent gas from escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

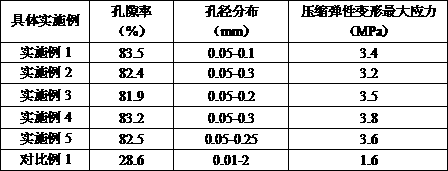

Examples

Embodiment 1

[0028] A method for preparing metal foam by coke composite foaming agent is characterized in that the specific steps are as follows:

[0029] (1) Mix 10kg of aluminum powder with a particle size of less than 0.5mm and 0.5kg of superfine coke with a particle size of 5-10μm, add 0.45% kg of dispersant barium stearate, and set the temperature in a high-speed mixer at 80-100 ℃, the rotation speed is 100~120r / min, the treatment time is 20min, and the dispersion is uniform, so that the dispersant forms a film and covers the surface of the metal powder and ultra-fine coke;

[0030] (2) After the mixed material obtained in step (1) is cooled to room temperature, mix the mixed material with water, and grind it in a kneader for 10 minutes to mix it evenly to form a paste, forming a stable viscous paste with a viscosity of 3500cP ; The consumption of the water is 20% of the mixed material quality.

[0031] (3) Raise the temperature of the viscous paste to make the superfine coke react w...

Embodiment 2

[0034] A method for preparing metal foam by coke composite foaming agent is characterized in that the specific steps are as follows:

[0035] (1) Mix 10kg of copper powder with a particle size of less than 0.5mm and 0.8kg of ultra-fine coke with a particle size of 5-10μm, add 0.56kg of dispersant zinc stearate in a high-speed mixer at a temperature of 80-100°C, The rotation speed is 100~120r / min, the processing time is 30min, and the dispersion is uniform, so that the dispersant forms a film and covers the surface of the metal powder and ultra-fine coke;

[0036](2) After the mixed material obtained in step (1) is cooled to room temperature, mix the mixed material with water, and grind it in a kneader for 15 minutes to mix it evenly to form a paste, forming a stable viscous paste with a viscosity of 6000cP ; The consumption of the water is 20% of the mixed material quality.

[0037] (3) Raise the temperature of the viscous paste to make the superfine coke react with water vap...

Embodiment 3

[0040] A method for preparing metal foam by coke composite foaming agent is characterized in that the specific steps are as follows:

[0041] (1) Mix 10kg of nickel powder with a particle size of less than 0.5mm and 1kg of superfine coke with a particle size of 5-10μm, add 0.4% kg of dispersant magnesium stearate, and set the temperature in a high-speed mixer at 80-100°C , the rotation speed is 100~120r / min, the processing time is 20min, and the dispersion is uniform, so that the dispersant forms a film and covers the surface of the metal powder and ultra-fine coke;

[0042] (2) After the mixed material obtained in step (1) is cooled to room temperature, mix the mixed material with water, and grind it in a kneader for 20 minutes to mix it evenly to form a paste, forming a stable viscous paste with a viscosity of 4000cP ; The consumption of the water is 35% of the mixed material quality.

[0043] (3) Raise the temperature of the viscous paste to make the superfine coke react w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com