Preparation method of esterified maltodextrin

A technology of maltodextrin and esterification, which is applied in the field of maltodextrin, can solve the problems of complex refining process and low yield, and achieve the effect of expanding application field, high yield and promoting esterification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

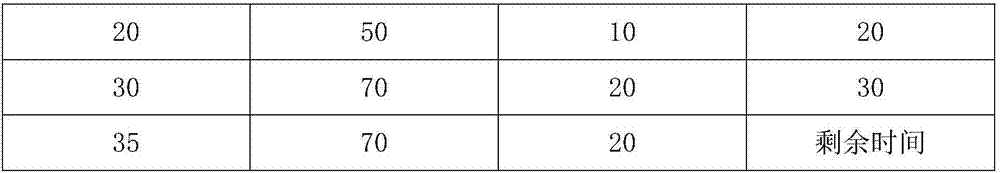

Examples

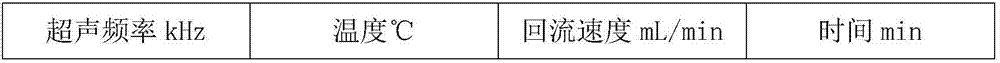

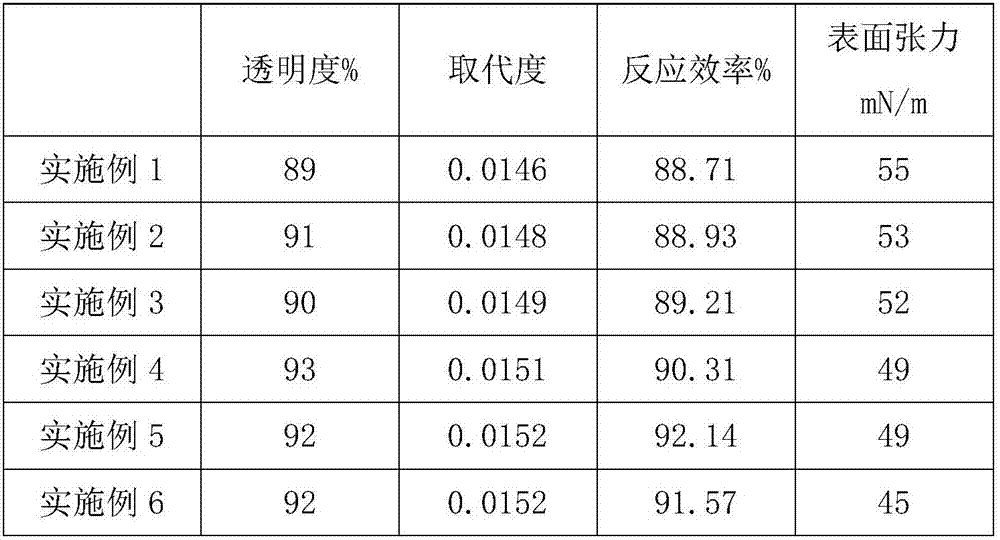

Embodiment 1

[0037] A preparation method of esterified maltodextrin, characterized in that: the preparation steps are as follows:

[0038] Step 1, adding maltodextrin into the aqueous ethanol solution, adding a pharmaceutical grade dispersant, stirring evenly to form a maltodextrin solution;

[0039] Step 2, slowly adding the acidifying agent dropwise into the maltodextrin solution, and ultrasonically reacting for 20 minutes at the same time, to obtain the acidified maltodextrin solution;

[0040] Step 3, put the acidified maltodextrin solution into the internal circulation reaction kettle, slowly add the pH regulator and modifier dropwise while ultrasonically reacting for 2 hours, to obtain the crude product of esterified maltodextrin;

[0041] Step 4, adding an inorganic initiator to the crude esterified maltodextrin, sealing, heating and pressurizing the internal circulation for 30 minutes, and filtering to obtain an esterified maltodextrin product;

[0042] Step 5: Put the esterified ma...

Embodiment 2

[0051] A preparation method of esterified maltodextrin, characterized in that: the preparation steps are as follows:

[0052] Step 1, adding maltodextrin into the aqueous ethanol solution, adding a pharmaceutical grade dispersant, stirring evenly to form a maltodextrin solution;

[0053] Step 2, slowly adding the acidifying agent dropwise into the maltodextrin solution, and ultrasonically reacting for 30 minutes at the same time, to obtain the acidified maltodextrin solution;

[0054] Step 3, put the acidified maltodextrin solution into the internal circulation reaction kettle, slowly add the pH regulator and modifier dropwise and ultrasonically react for 4 hours to obtain the crude esterified maltodextrin;

[0055] Step 4, adding an inorganic initiator to the crude product of esterified maltodextrin, reacting in a sealed, heated and pressurized internal cycle for 50 minutes, and filtering to obtain an esterified maltodextrin product;

[0056] Step 5: Put the esterified malto...

Embodiment 3

[0065] A preparation method of esterified maltodextrin, characterized in that: the preparation steps are as follows:

[0066] Step 1, adding maltodextrin into the aqueous ethanol solution, adding a pharmaceutical grade dispersant, stirring evenly to form a maltodextrin solution;

[0067] Step 2, slowly drop the acidifying agent into the maltodextrin solution, and at the same time ultrasonically react for 25 n to obtain the acidified maltodextrin solution;

[0068] Step 3, put the acidified maltodextrin solution into the internal circulation reaction kettle, slowly add the pH regulator and modifier while ultrasonically reacting 3, and obtain the crude product of esterified maltodextrin;

[0069] Step 4, adding the inorganic initiator to the crude esterified maltodextrin, sealing, heating and pressurizing the internal circulation for 30-50 minutes, and filtering to obtain the esterified maltodextrin product;

[0070] Step 5: Put the esterified maltodextrin product into a reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com