Diamond wire cooling liquid as well as preparation method and application thereof

A technology of diamond wire and cooling liquid, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of non-recycling, difficulty in processing waste cooling liquid, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

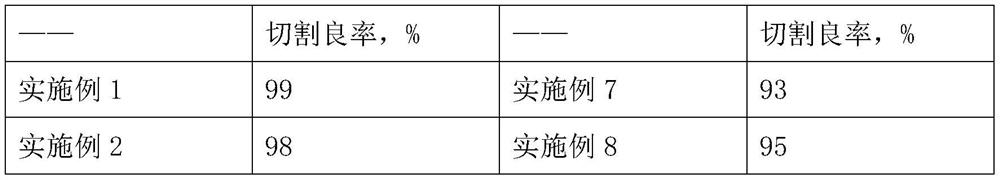

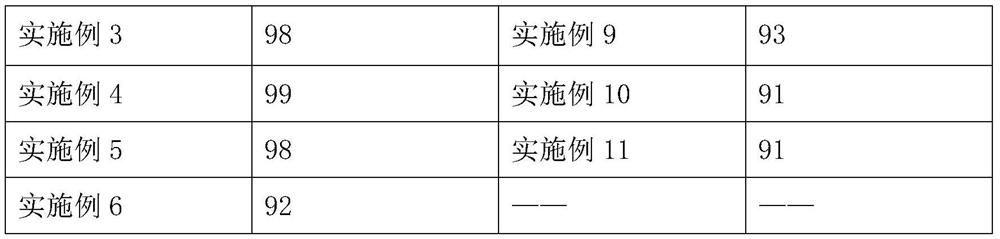

Examples

Embodiment 1

[0038](1) Weigh raw materials according to the number of parts by mass: 50 parts of water, 50 parts of polymer polyether, 5 parts of fatty alcohol polyoxyethylene ether, 8 parts of acetylene glycol polyoxyethylene ether, 3 parts of organic acid, and 3 parts of organic amine , 0.5 part of defoamer;

[0039] (2) Disperse fatty alcohol polyoxyethylene ether and acetylene glycol polyoxyethylene ether in water at 55°C to obtain a mixed solution; add polymer polyether to the mixed solution under stirring at 1000r / min, and then add organic acid in sequence , an organic amine, and a defoamer to obtain the diamond wire cooling liquid.

Embodiment 2

[0041] (1) Weigh raw materials according to the number of parts by mass: 80 parts of water, 64 parts of polymer polyether, 3 parts of fatty alcohol polyoxyethylene ether, 3 parts of acetylene glycol polyoxyethylene ether, 5 parts of organic acid, and 1 part of organic amine , 0.1 part of defoamer;

[0042] (2) Disperse fatty alcohol polyoxyethylene ether and acetylene glycol polyoxyethylene ether in water at 60°C to obtain a mixed solution; add polymer polyether to the mixed solution under stirring at 800r / min, and then add organic acid in sequence , an organic amine, and a defoamer to obtain the diamond wire cooling liquid.

Embodiment 3

[0044] (1) Weigh raw materials according to mass parts: 64 parts of water, 80 parts of polymer polyether, 4 parts of fatty alcohol polyoxyethylene ether, 4 parts of acetylene glycol polyoxyethylene ether, 3 parts of organic acid, 3 parts of organic amine , 0.3 parts of defoamer;

[0045] (2) Disperse fatty alcohol polyoxyethylene ether and acetylene glycol polyoxyethylene ether in water at 50°C to obtain a mixed solution; add polymer polyether to the mixed solution under stirring at 500r / min, and then add organic acid in sequence , an organic amine, and a defoamer to obtain the diamond wire cooling liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com