A kind of diamond wire cooling liquid and its preparation method and application

A technology of diamond wire and coolant, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of waste of materials, increase of environmental treatment burden, loss of crystal silicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

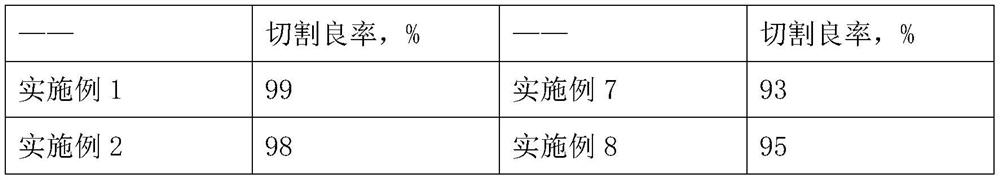

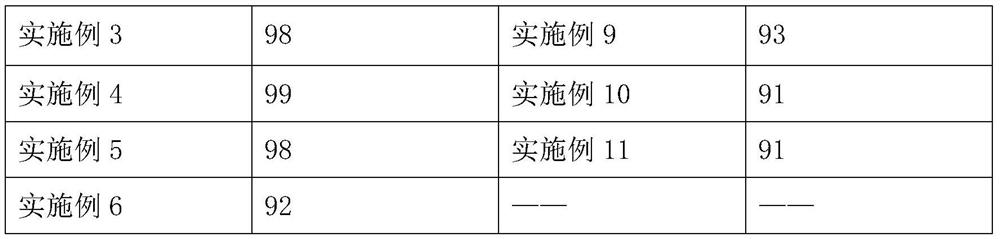

Examples

Embodiment 1

[0038](1) Weigh raw materials according to parts by mass: 50 parts of water, 50 parts of polymer polyethers, 5 parts of fatty alcohol polyoxyethylene ethers, 8 parts of acetylenic glycol polyoxyethylene ethers, 3 parts of organic acids, 3 parts of organic amines , 0.5 part of defoamer;

[0039] (2) Disperse fatty alcohol polyoxyethylene ether and acetylene glycol polyoxyethylene ether in water at 55°C to obtain a mixed solution; add polymer polyether to the mixed solution under stirring at 1000 r / min, and then add organic acid in turn , organic amine and defoamer to obtain the diamond wire cooling liquid.

Embodiment 2

[0041] (1) Weigh raw materials according to parts by mass: 80 parts of water, 64 parts of polymer polyethers, 3 parts of fatty alcohol polyoxyethylene ethers, 3 parts of acetylenic glycol polyoxyethylene ethers, 5 parts of organic acids, 1 part of organic amines , 0.1 part of defoamer;

[0042] (2) Disperse fatty alcohol polyoxyethylene ether and acetylene glycol polyoxyethylene ether in water at 60°C to obtain a mixed solution; add polymer polyether to the mixed solution under stirring at 800 r / min, and then add organic acid in turn , organic amine and defoamer to obtain the diamond wire cooling liquid.

Embodiment 3

[0044] (1) Weigh the raw materials according to the parts by mass: 64 parts of water, 80 parts of polymer polyethers, 4 parts of fatty alcohol polyoxyethylene ethers, 4 parts of acetylenic glycol polyoxyethylene ethers, 3 parts of organic acids, 3 parts of organic amines , 0.3 part of defoamer;

[0045] (2) Disperse fatty alcohol polyoxyethylene ether and acetylene glycol polyoxyethylene ether in water at 50°C to obtain a mixed solution; add polymer polyether to the mixed solution under stirring at 500 r / min, and then add organic acid in turn , organic amine and defoamer to obtain the diamond wire cooling liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com