Preparation method of fig concentrated solution Maillard reaction type perfume for cigarette

A Maillard reaction and tobacco flavor technology, which is applied in the field of cigarette flavors and fragrances, can solve the problems of bitterness and irritation, easy to affect taste, dark color, etc., and achieves reduction of bitterness and irritation, rich aroma, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

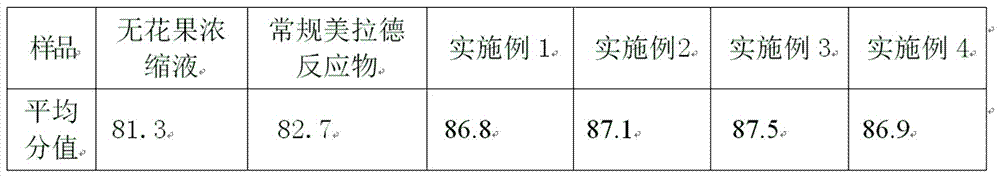

Examples

Embodiment 1

[0027] (1) After drying the figs, cut them into slices of 2-5 mm, add 3 times the quality of pure water, soak for 10 hours, and reflux extraction twice at 85°C for 3 hours each time, after the two extractions , filter and combine the filtrates to obtain a fig extract, which is cooled for later use.

[0028] (2) Add 0.4% of its mass non-starch polysaccharase to the extract in step (1), control the enzymatic hydrolysis temperature at 40°C, and process for 2.5 hours under constant stirring. After the enzymatic hydrolysis, add 5 times the mass of 95% ethanol solution to the enzymatic hydrolysis solution, mix well and let it stand at room temperature for 12 hours, after alcohol precipitation, filtration, and concentration under reduced pressure to a relative density of 1.0500±0.0050g / mL , to obtain fig concentrate.

[0029] (3) Put the fig concentrate into the Maillard reaction vessel, add alanine according to the mass ratio of 5%, add vitamin C according to 0.025% of the initial ...

Embodiment 2

[0032] (1) After drying the figs, cut them into slices of 2-5mm, add 4 times the quality of pure water, soak for 12 hours, and reflux extraction twice at 90°C for 4 hours each time, after the two extractions , filter and combine the filtrates to obtain a fig extract, which is cooled for later use.

[0033] (2) Add 0.6% of the mass of non-starch polysaccharase to the extract in step (1), control the enzymatic hydrolysis temperature at 45°C, and treat for 3 hours under constant stirring. After enzymatic hydrolysis, add 6 times the mass of 95% ethanol solution to the enzymatic hydrolysis solution, mix well and let it stand at room temperature for 18 hours, after alcohol precipitation, filtration, and concentration under reduced pressure to a relative density of 1.0500±0.0050g / mL , to obtain fig concentrate.

[0034] (3) Put the fig concentrate into the Maillard reaction vessel, add aspartic acid at a mass ratio of 8%, add vitamin C at 0.03% of the weight of the initial mixture, ...

Embodiment 3

[0037] (1) After drying the figs, cut them into slices of 2-5 mm, add 2.5 times the quality of pure water, soak for 9 hours, and reflux extraction twice at 75°C, each time for 3.5 hours, and the two extractions are over Finally, filter and combine the filtrates to obtain the fig extract, which is cooled for later use.

[0038] (2) Add 0.8% of its mass non-starch polysaccharase to the extract in step (1), control the enzymatic hydrolysis temperature at 50°C, and treat for 4 hours under constant stirring. After enzymatic hydrolysis, add 4 times the mass of 95% ethanol solution to the enzymatic hydrolysis solution, mix well and let it stand at room temperature for 20 hours, after alcohol precipitation, filtration, and concentration under reduced pressure to a relative density of 1.0500±0.0050g / mL , to obtain fig concentrate.

[0039](3) Put the fig concentrate into the Maillard reaction container, add proline according to the mass ratio of 10%, add vitamin C according to 0.02% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com