Capsule rhodobacter strain for degrading aspergillus flavus B1, application of capsule rhodobacter strain, degradation agent and application of degradation agent

A technology of capsulated rhodobacter and aspergillus flavus, which is applied in the field of aflatoxin degradation, can solve the problems of high energy consumption and insignificant effect, and achieve the effects of simplifying the process, shortening the production cycle, and eliminating toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the present invention, the preparation method of the acid-decomposed straw material preferably includes the following steps: mix and acidify the mass of the crushed moldy plant straw and the acidification solution in a volume ratio of 100mg:130ml, and perform acidification on the acidified mixture. After high-temperature and high-pressure treatment, the temperature of the high-temperature and high-pressure treated mixture is lowered to 36° C., neutralized to neutral with 1% ammonia water, and the acid-hydrolyzed straw mixture is obtained.

[0035] The invention also provides the application of the Aspergillus flavus B1 degradation agent in preparing animal feed.

[0036] In the present invention, the application of the Aspergillus flavus B1 degradation agent in the preparation of animal feed preferably comprises the following steps:

[0037] 1) Pretreating the mildewed plant stalks, adjusting the pH value to neutral, and then mixing with the Aspergillus flavus B1 deg...

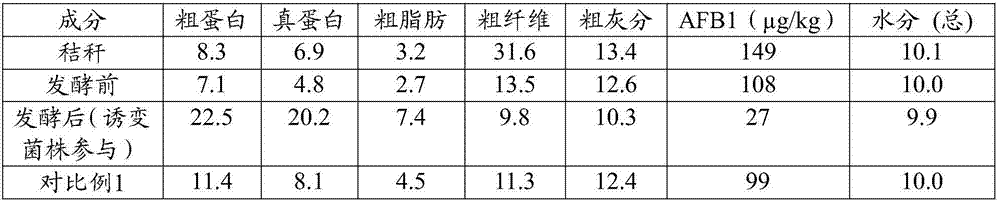

Embodiment 1

[0053] Activation of Rhodobacter capsulata, chemical-ultraviolet mutagenesis, and fermentative conversion of moldy straw acid hydrolyzate to reduce aflatoxin B1 to prepare feed include the following steps:

[0054] (1) Two chemical mutagenesis. The purchased capsulated Rhodobacter (Rhodobacter capsulatus (Rhodobacter capsulatus) is preserved in the China General Microorganism Culture Collection Management Center CGMCC, No. 1.3366) was inserted into the liquid activation culture for activation based on 28 ° C, and then transferred twice to make the strain Stable, culture conditions: 27°C, inoculum size 9%, culture time 5 days, shake well twice a day for static culture. 0.1 mL of the capsulated Rhodobacterium liquid (bacteria count 4.4 × 10 5 CFU / mL) was spread on the solid medium (I) and covered with a layer of 3mm solution layer (I). After 1 hour, the upper solution was sucked off, and deionized water was poured lightly and sucked 4 times repeatedly, and then the upper layer ...

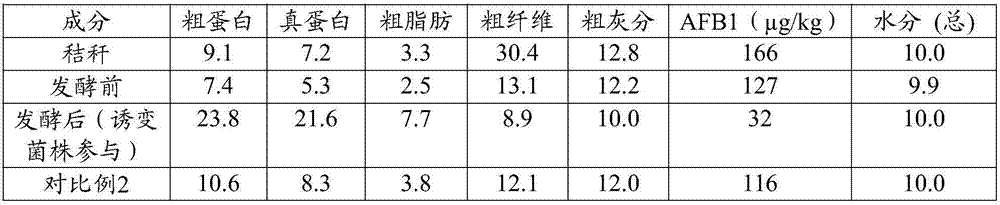

Embodiment 2

[0069] The mildewed corn stalks were placed in an incubator at 85°C to a constant weight, and after cooling, they were crushed to a 40-mesh sieve. Mix 100kg of crushed straw (moisture content 10.0%) with 100ml of 1% sulfuric acid solution, heat to 135°C for 2.5h, keep the pressure at 0.8MPa in a closed stainless steel container, then cool the mixture to 35°C and add 2% ammonia water for neutralization to neutrality (pH=7) to obtain the acidolysis straw mixture.

[0070] Get 100 parts of acid-hydrolyzed stalks and 9 parts of expanded cultured bacterial strains in Example 2 and mix them evenly in a 2L glass fermenter, so that the number of colonies contained in each gram of acid-hydrolyzed stalks is 3.1×10 6 CFU starter was mixed evenly in a 2L glass fermenter, and fermented under the conditions of light 800lux, temperature 36°C, and stirring speed 40r / min. When the pH of the fermented mash dropped to 6.2, 0.3% ammonia solution was added to adjust the pH to 7.8. Fermentation 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com